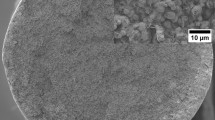

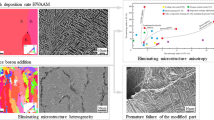

The present study compares two additive manufacturing methods, wire arc and electron beam ones, by analyzing the structural and mechanical characteristics of 3D printed Ti–Al–Zr–Mo–V alloy components. The macrostructure of the studied Ti–Al–Zr–Mo–V components is represented by columnar primary β grains of the Widmanstatten pattern with lamellar alpha colonies of different sizes and orientation. During the electron beam additive manufacturing (EBAM) process, the concentration of the α-stabilizing Al decreases from 3.81 ± 0.59 to 2.72 ± 0.53 wt.%. However, during the wire arc additive manufacturing (WAAM) process, the Al concentration is kept within the error range. The components printed by the EBAM method show anisotropy of mechanical properties. The ultimate strength is 757–767 MPa for the EBAM-fabricated components and 887– 896 MPa for the WAAM-fabricated components.

Similar content being viewed by others

References

B. A. Szost, S. Terzi, F. Martina, et al., Mater. Des., 89, 559–567 (2016); https://doi.org/10.1016/j.matdes.2015.09.115.

A. P. Zykova, A. V. Nikolaeva, A. V. Vorontsov, et al., Phys. Mesomech., 26, 107–125 (2023); https://doi.org/10.1134/S1029959923020017.

H. K. Rafi, N. V. Karthik, H. Gong, et al., J. Mater. Eng. Perform., 22, 3872–3883 (2013); https://doi.org/10.1007/s11665-013-0658-0.

S. A. Mantri, T. Torgerson, E. Ivanov, et al., Metall. Mater. Trans. A, 49, 806–810 (2018); https://doi.org/10.1007/s11661-017-4454-6.

M. Geetha, A. K. Singh, K. Muraleedharan, et al., J. Alloys Compd., 329, 264–271 (2001); https://doi.org/10.1016/S0925-8388(01)01604-8.

S. Liu and Y. C. Shin, Mater. Des., 164, 107552 (2019); DOI:https://doi.org/10.1016/j.matdes.2018.107552.

A. Gupta, C. J. Bennett, and W. Sun, Eng. Fail. Anal., 120, 105115 (2021); https://doi.org/10.1016/j.engfailanal.2020.105115.

N. Sanaei and A. Fatemi, Prog. Mater. Sci., 117, 100724 (2021); https://doi.org/10.1016/j.pmatsci.2020.100724.

K. Endoh, M. Thara, T. Inamura, et al., J. Alloys Compd., 695, 76–82 (2017); https://doi.org/10.1016/j.allcom.201.10.108.

D. Jafari, T. H. J. Vaneker, and I. Gibson, Mater. Des., 202, 109471 (2021); https://doi.org/10.1016/j.matdes.2021.109471.

E. A. Kolubaev, V. E. Rubtsov, A. V. Chumaevsky, et al., Phys. Mesomech., 25, 479–491 (2022); https://doi.org/10.1134/S1029959922060017.

V. K. Balla, J. Soderlind, and S. Bose, J. Mech. Behav. Biomed. Mater., 32, 335–344 (2014); https://doi.org/10.1016/j.jmbbm.2013.12.001.

Y. Kok, X. Tan, S. B. Tor, et al., Virt. Phys. Prototyp., 10, 13–21 (2015); https://doi.org/10.1080/17452759.2015.1008643.

A. P. Zykova, A. V. Vorontsov, A. V. Chumaevskii, et al., Russ. J. Non-Fer. Met., 63, 167–176 (2022); DOI:https://doi.org/10.3103/S1067821222020146.

V. Chawla, R. Jayaganthan, and R. Chandra, Mater. Charact. 59, 1015–1020 (2008); DOI:https://doi.org/10.1016/j.matchar.2007.08.017.

S. V. Fortuna, D. A. Gurianov, K. N. Kalashnikov, et al., Metall. Mater. Trans. A, 52, 857–870 (2021); https://doi.org/10.1007/s11661-020-06090-8.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Semenchuk, V.M., Nikolaeva, A.V., Savchenko, N.L. et al. Manufacturing of Ti–Al–Zr–Mo–V Alloy Components by Additive Methods. Russ Phys J 66, 1180–1188 (2024). https://doi.org/10.1007/s11182-023-03060-6

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-03060-6