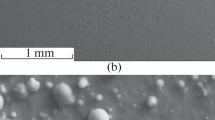

The paper analyzes the structure of quasi-equiatomic nanocrystalline ceramic (NbMoCrTiAl)N and (TiNbZrTaHf)N coatings formed by plasma-assisted vacuum arc deposition from multicomponent gas-metal plasma through simultaneous evaporation of Nb, Mo, Cr, TiAl cathodes and TiNbZrTaHf cathode in an argon–nitrogen mixture. The analysis shows that in the (NbMoCrTiAl)N coating, metal mononitrides are formed by the mechanism of internal stress relaxation. In the (TiNbZrTaHf)N coating, such relaxation is provided by the formation of nanosized lamellae in its columnar structure.

Similar content being viewed by others

References

B. Cantor, I. T. H. Chang, P. Knight, and A. J. B. Vincent, Mater. Sci. Eng. A, 375–377, 213–218 (2004); https://doi.org/10.1016/j.msea.2003.10.257.

J. W. Yeh, S.-K. Chen, S.-J. Lin, et al., Adv. Eng. Mater., 6, 299–303 (2004); https://doi.org/10.1002/adem.200300567.

T. K. Chen, T. T. Shun, J. W. Yeh, and M. S. Wong, Surf. Coat. Technol., 188–189, 193–200 (2004); https://doi.org/10.1016/j.surfcoat.2004.08.023.

Y. Zhang, High-Entropy Materials: Brief Introduction, Springer Nature, Singapore (2019).

Z. B. Bataeva, A. A. Ruktuev, I. V. Ivanov, et al., Obrab. Met. – Met. Work. Mater. Sci., 23, No. 2, 116–146 (2021); https://doi.org/10.17212/1994-6309-2021-23.2-116-146.

F. Marques F., M. Balcerzak, F. Winkelmann, et al., Energy Environ. Sci., 14, 5191–5227 (2021); https://doi.org/10.1039/d1ee01543e.

N. A. Azarenkov, O. V. Sobol, V. M. Beresnev, et al., Metallofiz. Noveishie Tekhnol., 2013, 35, No. 8, 1061–1084 (2013).

Y. A. Alshataif, S. Sivasankaran, F. A. Al‑Mufadi, et al., Met. Mater. Int., 26, 1099–1133 (2020); https://doi.org/10.1007/s12540-019-00565-z.

Yu. F. Ivanov, N. N. Koval, Yu. H. Akhmadeev, et al., Russ. Phys. J., 64, No. 12, 32–37 (2021); https://doi.org/10.1007/s11182-022-02578-5.

V. F. Gorban’, A. A. Andreev, L. R. Shaginyan, et al., J. Superhard Mater., J. Superhard Mater., 40, 88–101 (2018).

C. H. Lai, S. J. Lin, J. W. Yeh, and S. Y. Chang, Surf. Coat. Technol., 201, 3275 (2006); https://doi.org/10.1016/j.surfcoat.2006.06.048.

S. A. Firstov, V. F. Gorban’, A. O. Andreev, and N. A. Krapivka, Nauka Innov., 9, No. 5, 32–39 (2013).

Yu. F. Ivanov, Yu. H. Akhmadeev, N. N. Koval, et al., Russ. Phys. J., 65, No. 11, 1855–1861 (2023); https://doi.org/10.1007/s11182-023-02842-2.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Ivanov, Y.F., Akhmadeev, Y.H., Koval, N.N. et al. Structure and Phase State of Ceramic High-Entropy Alloy Coatings Formed by Plasma-Assisted Vacuum Arc Deposition. Russ Phys J 66, 829–834 (2023). https://doi.org/10.1007/s11182-023-03011-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-03011-1