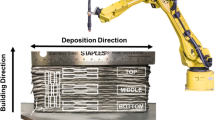

The paper studies the influence of wire-arc additive manufacturing process parameters of aluminum– manganese bronze CuAl9Mn2 products on the structure and mechanical properties of samples The microstructure of aluminum bronze is defined by the presence of α-Cu(Al) solid solution and residual martensitic β-phase of Cu3Al. Insignificant anisotropy of mechanical properties of the samples cut in sections parallel and perpendicular to the direction of printing has been revealed. Samples cut in the cross section parallel to the printing direction show the highest values of the tensile strength and less ductility compared to the samples cut in cross section perpendicular to the printing direction. The tensile strength values vary from 515 MPa to 591 MPa between blades cut along and across the ply application. The strength of the hot-rolled product (440 MPa) is 25% lower than the strength of the product obtained by the WAAM method (591 MPa). It is shown that a change in the heat input does not affect the average width of the dendritic grains in the cross section perpendicular to the printing direction. It was found that changing the printing mode can lead both to an increase in the mechanical properties of the samples and to violations of the geometry of the obtained samples.

Similar content being viewed by others

References

T. Feucht, J. Lange, M. Erven, et al., Constr. Robot., 4, 31 (2020).

S. W. Williams, F. Martina, A. C. Addison, et al., Mater. Sci. Technol., 32, No. 7, 641 (2016).

T. Artaza, A. Alberdi, M. Murua, et al., Procedia Manuf., 13, 778 (2017).

T. A. Rodrigues, V. Duarte, R. M. Miranda, et al., Materials, 12, 1121 (2019).

C. Liu, Z. Li, X. Pei, et al., Surf. Coat. Technol., 329, 42 (2017).

S. Selvi, A. Vishvaksenan, and E. Rajasekar, Def. Technol., 14, 28 (2018).

Y. Liang, J. Shen, S. Hu, et al., J. Mater. Process. Technol., 255, 161 (2018).

I. al Zamzami, B. Davison, and L. Susmel, Int. J. Fatigue, 123, 279 (2019).

I. al Zamzami, V. di Cocco, J. B. Davison, et al., Weld. World, 62, 1255 (2018).

S. M. Orzolek, J. K. Semple, and C. R. Fisher, Addit. Manuf., 56, 102859 (2022).

E. Aldalur, A. Suárez, and F. Veiga, J. Mater. Process. Technol., 297, 117271 (2021).

D. Ding, Z. Pan, S. van Duin, et al., Materials, 9, 652 (2016).

V. P. Gorbatenko and T. V. Novoselova, Materials Science [in Russian], El’Direct, Nevinnomyssk (2018).

S. Yoshida, T. Sasaki, M. Usui, and I. K. Park, Phys. Mesomech., 19, 41 (2016).

J. R. Davis, ed., ASM Specialty Handbook: Copper and Copper Alloys, ASM International, Materials Park (2001).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Semenchuk, V.M., Chumaevskii, A.V., Nepomnyaschiy, A.S. et al. Influence of 3D Printing Parameters of Aluminum–Manganese Bronze by Wire-Arc Additive Manufacturing on the Microstructure and Mechanical Properties. Russ Phys J 65, 1577–1583 (2023). https://doi.org/10.1007/s11182-023-02804-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-02804-8