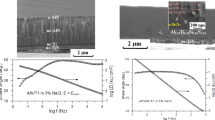

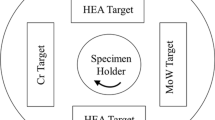

The paper studies the magnetron sputter-deposited multilayer, multicomponent Al–Si–N/Ni/Al–Si–N coating possessing higher corrosion resistance. Studied are the phase and elemental composition of the coating and its structural layers. It is found that all coating layers have a columnar structure. The structure of the Al–Si–N coating is nanocrystalline, while the structure of the nickel layer is finely crystalline. The X-ray diffraction (XRD) analysis shows that AlN and Si3N4 phases with the hexagonal closed packed crystal structure are present in the Al–Si–N layer, which is confirmed by the XRD patterns obtained on a transmission electron microscope. According to corrosion tests, the corrosion resistance of specimens coated by the Al–Si–N/Ni/Al–Si–N coating, is higher than that of uncoated specimens.

Similar content being viewed by others

References

P. Sambyal, G. Ruhi, S. Dhawan, et al., Prog. Org. Coat., 119, 203–213 (2018). DOI: https://doi.org/10.1016/j.porgcoat.2018.02.014.

J. Musil, G. Remnev, V. Legostaev, et al., Surf. Coat. Technol., 307, 1112–1118 (2016). DOI: https://doi.org/10.1016/j.surfcoat.2016.05.054.

D. Zhang, Z. Qi, B. Wei, et al., Surf. Coat. Technol., 309, 12–20 (2017). DOI: https://doi.org/10.1016/j.surfcoat.2016.11.042.

Wu Guizhi, Ma Shengli, Xu Kewei, J. Vac. Sci. Technol. A, 30, 021501 (2012). DOI: https://doi.org/10.1116/1.3676186.

M. S. Dorofeeva, T. I. Dorofeeva, B. P. Gritsenko, and V. P. Sergeev, in: Proc. 6th Int. Congress on Energy Fluxes and Radiation Effects, JPCS, 032067 (2018). DOI: https://doi.org/10.1088/1742-6596/1115/3/032067.

L. Jiang, J. A. Syed, Y. Gao, et al., Appl. Surf. Sci., 440, 1011–1021 (2018). DOI: https://doi.org/10.1016/j.apsusc.2018.01.145.

L. Zhang, S. Liu, H. Han, et al., Surf. Coat. Technol., 341, 95–102 (2018). DOI: https://doi.org/10.1016/j.surfcoat.2017.12.034.

S. Akhtar, A. Matin, A. M. Kumar, et al., Appl. Surf. Sci., 440, 1286–1297 (2018). DOI: https://doi.org/10.1016/j.apsusc.2018.01.203.

N. Petkov, T. Bakalova, T. Cholakova, et al., Superlattices Microstruct., 109, 402−413 (2017). DOI: https://doi.org/10.1016/j.spmi.2017.05.022.

T. A. Gubaidulina, T. I. Dorofeeva, V. P. Sergeev, and M. Fedorischeva, Metals, 12, No. 2, 254 (2022). DOI: https://doi.org/10.3390/met12020254.

T. I. Dorofeeva, T. A. Gubaidulina, V. P. Sergeev, et al., Russ. Phys. J., 63, No. 7, 1186–1194 (2020).

Xiurong Jiang, Fu-Chi Yang, Wei-Chih Chen, et al., Surf. Coat. Technol., 320, 138−145 (2017). DOI: https://doi.org/10.1016/j.surfcoat.2017.01.085.

J. Musil, M. Šašek, P. Zeman, et al., Surf. Coat. Technol., 202, 3485–3493 (2008). DOI: https://doi.org/10.1016/j.surfcoat.2007.12.024

Sonia, Mohammed Junaid Shekh, S. K. Sharma, and S. K. Mishra, Mater. Charact., 169, 110589 (2020). DOI: https://doi.org/10.1016/j.matchar.2020.110589.

H. Liu, W. Tang, D. Hui, et al., Thin Solid Films, 517, 5988–5993 (2009). DOI: https://doi.org/10.1016/j.tsf.2009.03.173.

C.-L. Chang and C.-S. Huang, Thin Solid Films, 519, 4923–4927 (2011). DOI: https://doi.org/10.1016/j.tsf.2011.01.054.

W. Y. Ho, C. H. Tsai, and C. H. Hsu, Adv. Mater. Res., 415–417, 1938–1941 (2011). DOI: https://doi.org/10.4028/www.scientific.net/amr.415-417.1938.

Y. Ye, Z. Liu, W. Liu, et al., Tribol. Int., 121, 410–419 (2018). DOI: https://doi.org/10.1016/j.triboint.2018.01.064.

A. Pélisson, M. Parlinska-Wojtan, H. Hug, and J. Patscheider, Surf. Coat. Technol., 202, 884–889 (2007). DOI: https://doi.org/10.1016/j.surfcoat.2007.05.094.

A. Pélisson-Schecker, H. J. Hug, and J. Patscheider, Surf. Coat. Technol., 257, 114–120 (2014). DOI: https://doi.org/10.1016/j.surfcoat.2014.08.053.

Rumana Akhtera, Zhifeng Zhou, Zonghan Xie, Paul Munroe, Appl. Surf. Sci., 538, 147987 (2021). DOI: https://doi.org/10.1016/j.apsusc.2020.147987.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 8, pp. 69–75, August, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Dorofeeva, T.I., Fedorischeva, M.V., Gubaidulina, T.A. et al. Structure and Phase Composition of Magnetronsputter-Deposited Corrosion Resistant Al–Si–N/Ni/Al–Si–N Coatings. Russ Phys J 65, 1311–1317 (2022). https://doi.org/10.1007/s11182-023-02767-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-023-02767-w