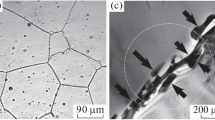

The results of an experimental study of the temperature dependence of mechanical properties and fracture mechanisms of cast multi-principal-element 20.0Fe–20.0Mn–20.0Cr–20.0Ni–20.0Co (high-entropy Cantor alloy), 19.7Fe–20.0Mn–20.0Cr–19.9Ni–19.0Co–1.4N and 20.4Fe–20.4Mn–20.3Cr–20.3Ni–17.0Co–1.6N (at.%) alloys under uniaxial static tension in the temperature interval from 77 K to 473 K are presented. The alloys possess an austenitic structure with dendritic segregations, and nitrogen-alloying is accompanied by the precipitation of the grain-boundary phase (at nitrogen concentration of 1.6 at.%). Their alloying with nitrogen causes an increase in the yield stress values and a stronger temperature dependence of σ0.2(T) over the whole experimental temperature range. In the Cantor alloy, containing no interstitial atoms, a test temperature decrease is accompanied by a simultaneous increase in its strength and elongation. This alloy is characterized by a ductile fracture in the entire test temperature range. Both nitrogen-containing alloys have higher strength properties and plasticity than those of the Cantor alloy. In the temperature range from 183 K to 473 K, both alloys fracture in the transgranular mode and contain numerous dimples on the fracture surfaces. Furthermore, there are secondary intergranular cracks observed on the fracture surfaces of the alloy with 1.6 at.% nitrogen. The elongation of both nitrogen-bearing alloys sharply decreases with the temperature going down to 77 K, and numerous brittle intergranular cracks are observed on the fracture surfaces. In the alloy with 1.4 at.% nitrogen, some regions with ductile transcrystalline fracture are also seen, while a portion of transgranular cleavage-like brittle facets is typical of the alloy with 1.6 at.% nitrogen. In other words, cast nitrogen-doped multicomponent alloys exhibit a ductile-to-brittle transition in a low-temperature deformation regime. According to the energy-dispersive SEM analysis, the low-temperature embrittlement of the alloy with 1.4 at.% nitrogen is due to the formation of grain-boundary segregations. Both these factors contribute to the intergranular fracture of the specimens. In alloy with 1.6 at.% nitrogen, the presence of brittle quasi-cleavages inside the austenite grains indicates the development of a ductile-to-brittle transition in the austenitic phase along with the brittle intergranular cracking due to the presence of grain-boundary nitrides.

Similar content being viewed by others

References

B. Cantor, I. T. H. Chang, P. Knight, and A. J.B. Vincent, Mater. Sci. Eng., 375–377, 213 (2004).

J. W. Yeh, S. K. Chen, S. J. Lin, et al., Adv. Eng. Mater., 6(5), 299 (2004).

Y. L. Chen, Y. H. Hu, C. A. Hsieh, et al., J. Alloys Compd., 481, 768 (2009).

D. B. Miracle and O. N. Senkov, Acta Mater., 122, 448 (2017).

A. Gali and E. P. George, Intermetallics, 39, 74 (2013).

F. Otto, A. Dlouhy, Ch. Somsen, et al., Acta Mater., 61, 5743 (2013).

Z. Han, W. Ren, J. Yang, et al., J. Alloys Compd., 791, 962 (2019).

I. V. Kireeva, Yu. I. Chumlyakov, A. V. Vyrodova, et al., Mater. Sci. Eng. A, 784, 139315 (2020).

O. N. Senkov, G. B. Wilks, J. M. Scott, and D. B. Miracle, Intermetallics, 19, 698 (2011).

M. Schneider and G. Laplanche, Acta Mater., 204, 116470 (2021).

Z. Wu, C. M. Parish, and H. Bei, J. Alloys Compd., 647, 815 (2015).

M. V. Klimova, A. O. Semenyuk, D. G. Shaysultanov, et al., J. Alloys Compd., 811, 152000 (2019).

E. G. Astafurova, K. A. Reunova, E. V. Melnikov, et al., Mater. Lett., 276, 128183 (2020).

Z. Li, Acta Mater., 164, 400 (2019).

E. Astafurova, E. Melnikov, S. Astafurov, et al., Mater. Lett., 285, 129073 (2021).

L. Guo, X. Ou, S. Ni, et al., Mater. Sci. Eng. A, 746, 356 (2019).

J. Y. Ko and S. I. Hong, J. Alloys Compd., 743, 115 (2018).

N. Saenarjhan, J. H. Kang, and S. J. Kim, Mater. Sci. Eng., A, 742, 608 (2019).

M. V. Klimova, D. G. Shaysultanov, A. O. Semenyuk, et al., J. Alloys Compd., 849, 156633 (2020).

V. G. Gavriljuk and H. Berns, High Nitrogen Steels, Springer Verlag, Berlin (1999).

I. Moravchik, V. Hornik, P. Minarik, et al., Mater. Sci. Eng. A, 781, 139242 (2020).

N. Saenarjhan, J. H. Kang, and S. J. Kim, Mater. Sci. Eng. A, 742, 608 (2019).

T. Masumura, N. Nakada, T. Tsuchiyama, et al., Acta Metall., 84, 330 (2015).

K. H. Lo, C. H. Shek, and J. K. L. Lai, Mat. Sci. Eng. R, 65, 39 (2009).

I. Moravcik, J. Cizek, L. de Almeida Gouvea, et al., Entropy, 21, 363 (2018).

I. Moravcik, H. Hadraba, L. Li, et al., Scr. Mater., 178, 391 (2020).

Z. He, N. Jia, H. Yan, et al., Int. J. Plast., 139, 102965 (2021).

J. Gubicza, IGI Global, 359 (2014).

I. V. Kireeva, Yu. I. Chumlyakov, Z. V. Pobedennaya, et al., Tech. Phys. Lett., 43 (13), 615 (2017).

A. Haglund, M. Koeheler, D. Catoor, et al., Intermetallics, 58, 62 (2015).

Yu. I. Chumlyakov, I. V. Kireeva, E. G. Zakharova, et al., Russ. Phys.J., 45, No. 3, 274 (2002).

G. Laplanche, A. Kostka, O. M. Horst, et al., Acta Mater., 118, 152 (2016).

Y. Tomota, Y. Xia, and K. Inoue, Acta. Mater., 5, 1577 (1998).

B. B. Straumal, Y. O. Kucheev, L. I. Efron, et al., J. Mater. Eng. Perf., 21, 667 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 2, pp. 111–120, February, 2022.

Rights and permissions

Springer Nature or its licensor holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reunova, K.A., Astafurov, S.V. & Astafurova, E.G. A Temperature Dependence of Mechanical Properties and Fracture Mechanisms in Cast Multiprincipal Element Alloys of the FeMnCrNiCo(N) System. Russ Phys J 65, 317–326 (2022). https://doi.org/10.1007/s11182-022-02638-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-022-02638-w