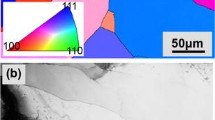

The paper presents the coarse- and ultrafine-grained microstructures, thermal diffusivity, and thermal capacity of commercial pure titanium at different deformation stages during quasi-static tension. The obtained new experimental results show that the ultrafine-grained microstructure of commercial pure titanium exerts a significant effect on its plastic deformation, fracture, and thermal properties.

Similar content being viewed by others

References

R. Z. Valiev, A. P. Zhilyaev, and T. G. Langdon, Bulk Nanostructured Materials: Fundamentals and Applications. John Wiley & Sons, New Jersey (2014).

L. B. Zuev, S. A. Barannikova, and A. G. Lunev, From Macro to Micro. Plastic Deformation [in Russian]. Nauka, Novosibirsk (2018).

S. M. Walley, Metall. Mater. Trans. A: Phys. Metall. Mater. Sci., 38A, 2629−2654 (2007).

M. A. Meyers and H. R. Pak, Acta Metall., 34, No. 12, 2493−2499 (1986).

D. R. Chichili, K. T. Ramesh, and K. J. Hempker, Acta Metall., 46, No. 3, 1025−1043 (1998).

B. K. Kardashev, M. V. Narykova, V. I. Betekhtin, et al., Fizich. Mezomekh., 22, No. 3, 71−76 (2019).

H. Wang, C. Ban, N. Zhao, et al., Mater. Lett., 266, 127485−127488 (2020).

O. A. Plekhov, S. V. Uvarov, O. B. Naimark, et al., Mat. Sci. Eng. A-Struct., 462, 367–369 (2007).

Yu. P. Sharkeev, E. V. Legostaeva, O. A. Belyavskaya, et al., Russ. Phys. J., 62, No. 8, 1349–1356 (2019).

Yu. P. Sharkeev, E. V. Legostaeva, A. Yu. Eroshenko, et al., Compos. Interface., 16, 535−546 (2009).

W. J. Parker, R. J. Jenkins, C. P. Butler, et al., J. Appl. Phys., 32, No. 9, 1679–1684 (1961).

ASTM E1269 Standard test Method for Determining Specific Heat Capacity by Differential Scanning Calorimetry (2011).

E. V. Kozlov, A. M. Glezer, N. A. Koneva, et al., Fundamentals of Plastic Deformation of Nanostructured Materials [in Russian], Fizmatlit, Moscow (2016).

T. M. Poletika, S. L. Girsova, and A. P. Pshenichnikov, Tech. Phys. Lett., 36, No. 4, 308–311 (2010).

A. V. Panin, V. E. Panin, Yu. I. Pochivalov, et al., Fizich. Mezomekh., 5, No. 4, 73−84 (2002).

V. V. Rybin, Large Plastic Deformations and Fracture of Metals [in Russian], Metallurgiya, Moscow (1986).

E. V. Legostaeva, Yu. P. Sharkeev, O. A. Belyavskaya, et al., Russ. Phys. J., 63, No. 11, 1867–1875 (2021).

V. I. Gorbatov, V. F. Polev, V. P. Pilugin, et al., High Temp., 51, 482−485 (2013).

Yu. P. Sharkeev, V. P. Vavilov, V. A. Skrypnyak, et al., Mat. Sci. Eng. A-Struct., 784, 139203–139221 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 10, pp. 141–148, October, 2021.

Rights and permissions

About this article

Cite this article

Legostaeva, E.V., Eroshenko, A.Y., Glukhov, I.A. et al. Ultrafine-Grained Microstructure and Thermal Properties of Titanium at Different Stages of Plastic Deformation. Russ Phys J 64, 1941–1948 (2022). https://doi.org/10.1007/s11182-022-02545-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-022-02545-0