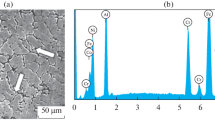

Wire arc additive manufacturing in pure argon is used to fabricate the high entropy alloy system Al–Co–Cr–Fe–Ni of the nonequiatomic composition: Al (35.67±1.34) at.%, Ni (33.79±0.46) at.%, Fe (17.28±1.83) at.%, Cr (8.28±0.15) at.%, and Co (4.99±0.09) at.%. According to the scanning electron microscopy, the high entropy alloy is a polycrystalline material with the grain size ranging between 4 and 15 μm. The second phase particles are observed along its grain boundaries. Mapping methods are used to show that the grains are enriched with aluminum and nickel, while the grain boundaries contain chromium and iron. A quasihomogeneous cobalt distribution is observed in the crystal lattice of the manufactured high entropy alloy. Tensile strength testing of the material shows its fracture by a transcrystalline rupture mechanism. The formation of brittle cracks occurs along the grain boundaries and point intersections, i.e., in places containing secondary phase inclusions. It is supposed that the higher brittleness of the high entropy alloy is caused by a nonuniform distribution of elements in the alloy microstructure and the presence of discontinuities of different shape in the bulk material.

Similar content being viewed by others

References

E. P. George, W. A. Curtin, and C. C. Tasan, Acta Mater., 18, 435−474 (2020).

Y. F. Ivanov, K. A. Osintsev, V. E. Gromov, S. V. Konovalov, and I. A. Panchenko, Steel Transl., 51, No. 1, 27−32 (2021).

A. S. Rogachev, Phys. Met. Metallogr., 121, No. 8, 733–764 (2020).

А. D. Pogrebnyak, A. A. Bagdasaryan, I. V. Yakushenko, and V. M. Beresnev, Russ. Chem. Rev., 83, No. 11, 1027–1061 (2014).

A. Kilmametov, R. Kulagin, A. Mazilkin, et al., Scripta Mater., 158, 29–33 (2019).

H. Cheng, Y. Xie, Q. Tang, et al., Trans. Nonferrous Met. Soc. China, 28, 1360–1367 (2018).

Q. Shen and X. Kong, J. Mater. Sci. Technol., 74, 136−142 (2021).

Y. Geng, S. V. Konovalov, and X. Chen, Prog. Phys. Met., 21, No. 1, 26−45 (2020).

J. M. Wu, S. J. Lin, J. W. Yeh, et al., Wear, 261, 513−519 (2006).

M. H. Chuang, M. H. Tsai, W. R. Wang, et al., Acta Mater., 59, 6308−6317 (2011).

Y. F. Kao, T. D. Lee, S. K. Chen, et al., Corros. Sci., 52, 1026−1034 (2012).

Q. Wang, Y. Ma, B. Jiang, et al., Scripta Mater., 120, 85−89 (2016).

T. Xiong, S. Zheng, J. Pang, et al., Scripta Mater., 186, 336−340 (2020).

R. John, A. Karati, J. Joseph, et al., J. Alloys Compd., 835, 155424 (2020).

X. Jin, Y. Liang, L. Zhang, et al., Mater. Sci. Eng. A, 745, 137−143 (2019).

Y. Liu, J. Chen, Z. Li, et al., J. Alloys Compd., 780, 558−564 (2019).

M. Chen, L. Lan, X. Shi, et al., J. Alloys Compd., 777, 180−189 (2019).

S. Qiu, X.-C. Zhang, J. Zhou, et al., J. Alloys Compd., 846, 156321 (2020).

Y. Zhang, T. T. Zuo, Z. Tang, et al., Prog. Mater. Sci., 61, 1–93 (2014).

D. B. Miracle and O. N. Senkov, Acta Mater., 122, 448–511 (2017).

B. S. Murty, J. W. Yeh, S. Ranganathan, and P. P. Bhattacharjee, High-Entropy Alloys, Elsevier, Amsterdam (2019).

Y. Zhang, High-Entropy Materials. A Brief Introduction, Springer Nature (2019).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 9, pp. 103–108, September, 2021.

Rights and permissions

About this article

Cite this article

Ivanov, Y.F., Gromov, V.E., Osintsev, K.A. et al. Deformation and Fracture of High Entropy AlCoCrFeNi Alloy. Russ Phys J 64, 1697–1702 (2022). https://doi.org/10.1007/s11182-022-02509-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-022-02509-4