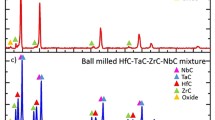

Structure formation during hot pressing of an equimolar powder mixture HfC–ZrC–TiC–NbC in the temperature range from 1400 to 1900°C is investigated. It is found that a monophase substitutional solid solution (Hf, Zr, Ti, Nb)C based on hafnium carbide forms at a temperature of 1700°C. It is shown that the formation of the ceramic solid solution (Hf, Zr, Ti, Nb)C proceeded in many stages with the formation of intermediate two- and three-component ceramic solid solutions (Hf, Zr)C, (Nb, Zr)C, and (Hf, Zr, Ti)C and their subsequent dissolution. The resulting ceramic multicomponent substitutional solid solution (Hf, Zr, Ti, Nb)C has improved mechanical properties compared to similar properties of initial carbides: E = (616 ± 77) GPa, H = (36 ± 8) GPa, and K1C = ( 3.4 ± 0.5) MPa ∙ m1/2.

Similar content being viewed by others

References

J. W. Yeh, S.-K. Chen, S.-J. Lin, et al., Adv. Eng. Mater., 6, No. 5, 299–303 (2004).

R. A. Andrievskii, Usp. Fiz. Nauk, 187, Vyp. 3, 296–310 (2017).

J. W. Yeh, JOM, 65, No. 12, 1759–1771 (2013).

Y. Zhang, T. T. Zuo, Z. Tang, et al., Prog. Mater. Sci., 61, 1–93 (2014).

J. W. Yeh, JOM, 67, No. 10, 2254–2261 (2015).

B. S. Murty, High-Entropy Alloys, Elsevier (2019).

C. M. Rost, E. Sachet, T. Borman, et al., Nat. Commun., 6, No. 1, 1–8 (2015).

Y. Dong, K. Ren, Y. Lu, et al., J. Eur. Ceram. Soc., 39, No. 7, 2574–2579 (2019).

J. Chen, W. Liu, J. Liu, et al., J. Phys. Chem. C, 123, No. 29, 17735–17744 (2019).

Z. Zhao, H. Xiang, F. Z. Dai, et al., J. Mater. Sci. Technol., 35, No. 10, 2227–2231 (2019).

J. Zhou, J. Zhang, F. Zhang, et al., Ceram. Int., 44, No. 17, 22014–22018 (2018).

A. Sarkar, L. Velasco, D. Wang, et al., Nat. Commun., 9, No. 1, 1–9 (2018).

Y. Zheng, Y. Yi, M. Fan, et al., Energy Storage Mater., 23, 678–683 (2019.

Q. Wang, A. Sarkar, D. Wang, et al., Energy Environ. Sci., 12, No. 8, 2433–2442 (2019).

B. Ye, T. Wen, D. Liu, and Y. Chu, Corros. Sci., 153, 327–332 (2019).

J. W. Yeh, Y. L. Chen, S. J. Lin, and S. K. Chen, Mater. Sci. Forum. Trans Tech Publications Ltd, 560, 1–9 (2007).

A. J. Wright, Q. Wang, C. Huang, et al., J. Eur. Ceram. Soc., 40, No. 5, 2120– 2129 (2020).

A. J. Wright and J. Luo, J. Mater. Sci., 55, No. 23, 9812–9827 (2020).

K. Niihara, R. Morena, and D. P. H. Hasselman, J. Mater. Sci. Lett., 1, No. 1, 13–16 (1982).

H. Bittermann and P. Rogl, J. Phase Equilibria., 23, 218–235 (2002).

O. Adjaoud, G. Steinle-Neumann, B. P. Burton, and A. Van de Walle, Phys. Rev. B, 80, No. 13, 134112 (2009).

X. G. Wang, J. X. Liu, Y. M. Kan, and G. J. Zhang, J. Eur. Ceram. Soc., 32, No. 8, 1795–1802 (2012).

Y. Li, H. Katsui, and T. Goto, Ceram. Int., 41, No. 10, 14258–14262 (2015).

S. V. Rempel and A. I. Gusev, Phys. Chem. Chem. Phys., 22, No. 26, 14918–14931 (2020).

E. Castle, T. Csanadi, S. Grasso, et al., Sci. Rep., 8, No. 1, 1–12 (2018).

A. A. Rempel and B. R. Gelchinskii, Izv. Vyssh. Uchebn. Zaved. Chern. Metallurg., 63, No. 3–4, 248–253 (2020).

C. Oses, C. Toher, and S. Curtarolo , Nat. Rev. Mater., 1 – 15 (2020).

I. V. Kireeva, Yu. I. Chumlyakov, Z. V. Pobedennaya, et al., Russ. Phys. J., 63, No. 1, 134 – 141 (2020).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 7, pp. 18–23, July, 2021.

Rights and permissions

About this article

Cite this article

Wang, D., Mirovoy, Y.A., Burlachenko, A.G. et al. Structure Formation in Equimolar Mixture of HfC–ZrC–TiC–NbC Carbides. Russ Phys J 64, 1191–1197 (2021). https://doi.org/10.1007/s11182-021-02443-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-021-02443-x