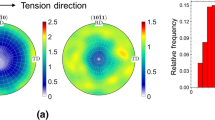

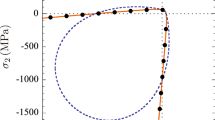

Sintered yttrium-stabilized zirconia is numerically and experimentally investigated during the Brazilian test. The strain and fracture of homogeneous and inhomogeneous cylindrical specimens under diametral compression are numerically simulated within the framework of mechanics of continuum mechanics. The specimen inhomogeneity is phenomenologically described by random assignment of the strength characteristics in computational cells. Unlike a homogeneous specimen, the strain localization and the formation of numerous fragments at fracture are observed in an inhomogeneous specimen. It is established that the zirconia strain is macroscopically localized. It is shown that sizes of coherently diffracting domains of the tetragonal phase and microdistortion of the lattice after sintering change compared to the initial state and differ for different fragments of a fractured specimen. The internal microstresses on different fragment surfaces change in the range 245–320 MPa depending on the arising strain inhomogeneity. The strain localization correlates with the inhomogeneity of the microstresses arising in the material undergoing deformation. The quantitative and qualitative agreement of the calculated results with the experimental data is observed.

Similar content being viewed by others

References

L. B. Zuev, V. I. Danilov, and S. A. Barannikova, Physics of Macrolocalization of a Plastic Flow [in Russiam], Nauka, Novosibirsk (2008).

2. I. A. Razumovskii, Interference and Optical Methods of Mechanics of a Deformable Soids [in Russian], Publishing House of Moscow State University, Moscow (2007).

A. Yu. Smolin, G. M. Eremina, and S. Yu. Korostelev, Russ. Phys. J., 62, No. 8, 1445–1454 (2019).

L. B. Zuev, Autowave Plasticity. Localization and Collective Modes [in Russian], Fizmatlit, Moscow (2018).

P. V. Makarov, I. Yu. Smolin, I. P. Prokopinsky, et al., Int. J. Fract., 100, No. 2, 121–131 (1999); https://doi.org/10.1023/A:1018765801332.

S. A. Barannikova, S. P. Buyakova, L. B. Zuev, et al., Pis’ma Zh. Tekhn. Fiz., 33, No. 11, 57–64 (2007).

I. N. Sevostyanova, T. Yu. Sablina, N. L. Savchenko, et al., IOP Conf. Ser.: Mater. Sci. Eng., 447, 012022-1-012022-4 (2018); https://doi.org/10.1088/1757-899X/447/1/012022.

M. Z. Sheikh, Z. Wang, B. Du, et al., Ceram. Int., 45, 7931–7944 (2019); https://doi.org/10.1016/j.ceramint.2019.01.106.

D. Li and L. N. Y. Wong, Rock Mech. Rock Eng., 46, 269–287 (2003); https://doi.org/10.1007/s00603-012-0257-7.

M. Mousavi Nezhad, Q. J. Fisher, E. Gironacci, et al., Rock Mech. Rock Eng., 51, 1755–1775 (2018); https://doi.org/10.1007/s00603-018-1429-x.

V. Yu. Goltsev, A. V. Osintsev, and A. S. Plotnikov, Lett. Mater., 7, No. 1, 21–25 (2017); https://doi.org/10.22226/2410-3535-2017-1-21-25.

K. Matsui, H. Horikoshi, N. Ohmichi, et al., J. Am. Ceram. Soc., 86, 1401–1408 (2003); https://doi.org/10.1111/j.1151-2916.2003.tb03483.x.

Ya. S. Umanskii, Yu. A. Skakov, A. N. Ivanov, et al., Crystallography, Radiography, and Electron Microscopy [in Russian], Metallurgiya, Moscow (1982).

K. I. Grant, R. D. Rawlings, and R. J. Sweeney, Mater. Sci. Mater. Med., 12, No. 6, 557–564 (2001).

S. P. Timoshenko and J. N. Goodier, Theory of Elasticity [Russian translation], Nauka, Moscow (1975).

C. C. Garcia-Fernandez, C. Gonzalez-Nicieza, M. I. Alvarez-Fernandez, et al., Int. J. Rock Mech. Min. Sci., 103, No. 3, 254-265 (2018); https://doi.org/10.1016/j.ijmms.2018.01.45.

M. A. Sutton, J. J. Orteu, and H. Schreier, Image Correlation for Shape, Motion and Deformation Measurements. Theory and Applications, Springer, Berlin; Heidelberg (2009).

I. N. Sevostyanova, T. Yu. Sablina, V. V. Gorbatenko, et al., Tech. Phys. Lett., 45, No. 9, 943–946 (2019); https://doi.org/10.1134/S1063785019090281.

V. Le Corre, N. Brusselle-Dupend, and M. Moreaud, Mech. Mat., 114, 161–171 (2017); https://doi.org/10.1016/j.mechmat.2017.08.002.

V. A. Mikushina, I. Yu. Smolin, Vestn. Tomsk. Gosud. Univ. Matem. Mekh., No. 58, 99–108 (2019); https://doi.org/10.17223/19988621/58/8.

M. L. Wilkins, Computer Simulation of Dynamic Phenomena, Springer Verlag, Berlin; Heidelberg (1999).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 6, pp. 70–76, June, 2020.

Rights and permissions

About this article

Cite this article

Kulkov, S.N., Smolin, I.Y., Mikushina, V.A. et al. Studying Strain Localization in Brittle Materials during the Brazilian Test. Russ Phys J 63, 976–983 (2020). https://doi.org/10.1007/s11182-020-02126-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-020-02126-z