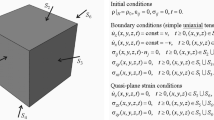

Plastic strain localization and fracture in the nugget and thermo-mechanically affected zone of a friction stir welded Al6061-T6 alloy are numerically investigated. Dynamic boundary-value problems are solved by the finite-difference method. A procedure for generating ordered and disordered polycrystalline microstructures experimentally observed in different weld zones is developed. A physically-based relaxation constitutive equation is developed to describe dynamic thermomechanical response of the aluminum alloy. Calculations of microstructure tension in polycrystals are performed. The effect of the degree of order and strain rate on the material dynamic strength and fracture are studied.

Similar content being viewed by others

References

V. P. Singh, J. Mater. Res. Technol., (2020). https://doi.org/10.1016/j.jmrt.2020.01.008.

R. S. Mishra and Z. Y. Ma, Mat. Sci. Eng. R., 50, 1–78 (2005).

C. B. Fuller, M. W. Mahoneya, M. Calabresea, et al., Mat. Sci. Eng. A-Struct., 527, 2233–2240 (2010).

S. Mironov, K. Masaki, Y. S. Sato, et al., Scripta Mater., 67, 983–986 (2012).

H. J. Liu, J. C. Hou, and H. Guo, Mater. Design, 50, 872–878 (2013).

O. Lorraina, V. Favier, H. Zahrounic, et al., J. Mater. Process. Tech., 210, 603– 609 (2010).

M. Dumont et al., Acta Mater., 54, 4793–4801 (2006).

M. F. X. Muthua and V. Jayabalan, J. Mat. Process. Tech., 217, 105–113 (2015).

H. J. Aval, Mater. Design, 67, 413–421 (2015).

H. M. Rao, W. Yuan, and H. Badarinarayan, Mater. Design, 66, 235–245 (2015).

M. H. Shojaeefard, Mater. Design, 64, 660–666 (2014).

A. Simar, Prog. Mater. Sci., 57, 95–183 (2012).

A. Timesli, B. Braikat, H. Lahmam, et al., Eng. Anal. Bound. Elem., 50, 372– 380 (2015).

H. Su, C. S. Wu, A. Pittner, et al., Energy, 77, 720–731 (2014).

G. Q. Chen, Comp. Mater. Sci., 79, 540–546 (2013).

S. D. Ji, Comp. Mater. Sci., 63, 218–226 (2012).

W. Pan, Int. J. Plasticity, 48, 189–204 (2013).

H. H. Cho, Acta Mater., 61, 2649–2661 (2013).

R. S. Saluja, R. G. Narayanan, and S. Das, Comp. Mater. Sci., 58, 87–100 (2012).

K. L. Nielsen, Int. J. Solids Struct., 47, 2359–2370 (2010).

R. Citarella, P. Carlone, M. Lepore, et al., Adv. Eng. Softw. Workst., 80, 47–57 (2015).

W. Lee, Int. J. Plasticity, 25, 1626–1654 (2009).

D. E. Boyce, P. R. Dawson, B. Sidle, et al., Comp. Mater. Sci., 38, 158–175 (2006).

V. A. Romanova, Phys. Mesomech., 22, No. 4, 296–306 (2019).

E. S. Emelianova, V. A. Romanova, R. R. Balokhonov, et al., Russ. Phys. J., 62, No. 9, 1539–1552 (2019).

R. R. Balokhonov, V. A. Romanova, S. Schmauder, et al., Theor. Appl. Frac. Mec., 101, 342–355 (2019).

R. Balokhonov, Phys. Mesomech., 23, No. 2, 296–306 (2020).

A. P. Babichev, N. A. Babushkina, A. M. Bratkovckii, et al., Physical Quantities. Reference book [in Russian] (Ed. I. S. Grigorieva and E. Z. Melikhova), Energoizdat, Moscow (1991).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 5, pp. 10–18, May, 2020.

Rights and permissions

About this article

Cite this article

Balokhonov, R.R., Romanova, V.A., Sergeev, M.V. et al. Influence of Polycrystalline Structure on Dynamic Strength and Fracture Character of an Aluminum Alloy in Different Welding Joint Zones. Russ Phys J 63, 721–730 (2020). https://doi.org/10.1007/s11182-020-02090-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-020-02090-8