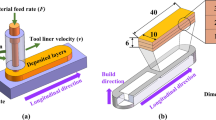

Samples of AA5356 aluminum alloy manufactured by the electron-beam additive method and modified using the friction stir processing method have been investigated. Processing was carried out along and across the sample growth direction. It has been established that pores formed in the 3D-printing process are eliminated during friction stir processing by the severe thermo-mechanical action. It has been found that the modes are not the same for different processing directions. As a result of adjustment of the processing parameters, it has been revealed that a higher loading force must be applied to form a high-strength stir zone across the direction of layers deposition. This is caused by the interlayer boundaries that were formed during layer deposition process and offered greater mechanical resistance to the tool.

Similar content being viewed by others

References

T. DebRoy, H. L. Wei, J. S. Zuback, et al., Prog. Mater. Sci., 92, 112–224 (2018).

E. Brandl, A. Schoberth, and C. Leyens, Mater. Sci. Eng. A, 532, 295–307 (2012).

D. Herzog, V. Seyda, E. Wycisk, and C. Emmelmann, Acta Mater., 117, 371–392 (2016).

W. S. W. Harun, M. S. I. N. Kamariah, N. Muhamad, et al., Powder Technol., 327, 128–151 (2018).

B. Wysocki, P. Maj, R. Sitek, et al., Appl. Sci., 7, 657 (2017).

B. Wu, Z. Pan, D. Ding, et al., J. Mater. Process. Technol., 258, 97–105 (2018).

M. J. Bermingham, L. Nicastro, D. Kent, et al., J. Alloys Compd., 753, 247–255 (2018).

P. L. Threadgill, A. J. Leonard, H. R. Shercliff, and P. J. Withers, Int. Mater. Rev., 54, 49–93 (2009).

M. Koilraj, V. Sundareswaran, S. Vijayan, and S. R. K. Rao, Mater. Des., 42, 1–7 (2012).

G. Rambabu, D. B. Naik, C. H. V. Rao, et al., Def. Technol., 11, No. 4, 330–337 (2015).

Q. Li and V. L. Popov, Phys. Mesomech., 20, No. 5, 91–95 (2017).

A. A. Eliseev, S. V. Fortuna, T. A. Kalashnikova, et al., Russ. Phys. J., 60, No. 6, 1022–1026 (2017).

M. Y. Murashkin, A. R. Kil’mametov, and R. Z. Valiev, Phys. Met. Metallogr., 106, No. 1, 90–96 (2008).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 9, pp. 26–33, September, 2019.

Rights and permissions

About this article

Cite this article

Kalashnikova, T.A., Chumaevskii, A.V., Rubtsov, V.E. et al. Structural Heredity of the Aluminum Alloy Obtained by the Additive Method and Modified Under Severe Thermomechanical Action on Its Final Structure and Properties. Russ Phys J 62, 1565–1572 (2020). https://doi.org/10.1007/s11182-020-01877-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-020-01877-z