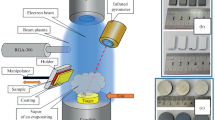

Results of using an electron beam formed by a forevacuum plasma electron source to sinter metalloceramic materials in powder form are reported. As the materials to be sintered, we used mixtures of titanium powder and an aluminum-oxide or zirconium-oxide based ceramic powder. Sintering was performed using a narrowly focused beam directed onto the surface of the metalloceramic powder. It has been shown that using a mixture of finely dispersed zirconium dioxide or aluminum oxide powder with titanium allows one, by using the electron-beam method in the forevacuum pressure region, to obtain a metalloceramic sample with a titanium concentration gradient over the volume of the sample.

Similar content being viewed by others

References

E. N. Kablov, Metally Evrazii, No. 3, 10–15 (2012).

N. Cherradi, A. Kawasaki, and M. Gasik, Compos. Part B-Eng., 4, No. 8, 883–894 (1994).

A. S. Chainkova, L. A. Orlova, N. V. Popovich, et al., Aviats. Mater. Tekhnol., No. S6, 52–58 (2014).

E. N. Kablov, Aviats. Mater. Tekhnol., No. 1 (34), 3–33 (2015).

P. Boch and J. C. Nièpce, Ceramic Materials: Processes, Properties, and Applications, John Wiley & Sons, New York (2010).

A. Mortensen, Int. Mater. Rev., 6, 239–265 (1995).

M. Naebe and K. Shirvanimoghaddam, Appl. Mater. Today, 5, 223–245 (2016).

P. Shanmugavel, G. B. Bhaskar, M. Chandrasekaran, et al., Eur. J. Sci. Res., 68, No. 3, 412–439 (2012).

B. Kieback, A. Neubrand, and H. Riedel, Mater. Sci. Eng. A, 362, 81–105 (2003).

T. Liu, Q. Wang, A. Gao, et al., Scripta Mater., 57, No. 11, 992–995 (2007).

L. Marin, Int. J. Sol. Struct., 42, No. 15, 4338–4351 (2005).

S. J. Marković, J. Eur. Ceram. Soc., 29, 2309–2316 (2009).

H. Yuan et al., Int. J. Refract. Met. H., 34, 13–417 (2012).

A. Teber et al., Int. J. Refract. Met. H., 30, 64–70 (2012).

Z. Qiao et al., Int. J. Refract. Met. H., 38, 7–14 (2013).

J. Wang, J. Am. Ceram. Soc., 89, 1977–1984 (2006).

W. Yan, W. Ge, J. Smith, et al., Acta Mater., 115, 403–412 (2016).

V. Burdovitsin, A. Klimov, and E. Oks, Tech. Phys. Lett., 35, 511–513 (2009).

V. Burdovitsin, A. Klimov, A. Medovnik, and E. Oks, Plasma Sources Sci. Technol., 19, No. 5, 055003 (2010).

A. Klimov, I. Bakeev, E. Oks, and A. Zenin, Laser Part. Beams, 37, No. 2, 203–208 (2019).

É. S. Dvilis, V. A. Burdovitsin, A. O. Khasanov, et al., Fundamental’nye Issled., No. 10-2, 270–279 (2016).

V. Burdovitsin, A. Zenin, A. Klimov, et al., Adv. Mater. Res., 872, 150–156 (2014).

A. V. Kazakov, A. S. Klimov, and A. A. Zenin, Proc. ТUSUR, No. 2, Part 2 (26), 186–189 (2012).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 7, pp. 25–30, July, 2019.

Rights and permissions

About this article

Cite this article

Klimov, A.S., Zenin, A.A., Bakeev, I.Y. et al. Formation of Gradient Metalloceramic Materials Using Electron-Beam Irradiation in the Forevacuum. Russ Phys J 62, 1123–1129 (2019). https://doi.org/10.1007/s11182-019-01826-5

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-019-01826-5