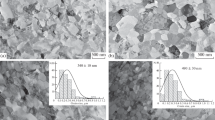

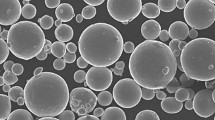

This paper is focused on a clarification and analysis of the regularities of formation of the structure and properties of samples of the titanium-based alloy VT6, obtained by methods of conventional metallurgy and formed by layered selective electron-beam sintering in vacuum (using the Arcam A2X (3D printer) system (Arcam, Sweden)) of VT6 titanium powder with particle size 40–100 μm. Additional modification of the samples was realized by irradiating the surface with an intense pulsed electron beam (15 keV, 45 J/cm2, 200 μs, 10 pulses, 0.3 s–1, 3.5·10–2 Pa). It is shown that the action of a pulsed electron beam on the surface of samples formed by layered selective electron-beam sintering leads to a significant reduction in the porosity of the surface layer of the material and formation in the surface layer of a polycrystalline structure (grain size 15–60 μm) with a substructure in the form of crystallization cells (cell size 0.5–1.2 μm). Electron-beam processing of samples prepared by methods of conventional metallurgy for the indicated electron-beam parameters leads to the formation in the surface layer of a polycrystalline structure (grain size 50–800 μm) with a laminar intragrain substructure. Mechanical tests, performed by stretching flat samples, showed that the highest combination of mechanical strength and plasticity is possessed by samples obtained by layered selective electron-beam sintering with subsequent irradiation by an intense pulsed electron beam.

Similar content being viewed by others

References

B. Evans, Practical 3D Printers: The Science and Art of 3D Printing, Apress, New York (2012).

S. L. Campanelli et аl., Polytechnic of Bari, Department of Management and Mechanical Engineering, Viale Japigia, 182 Italy [http://cdn.intechweb.org/pdfs/12285.pdf].

E. Louvis et аl., J. Mater. Proc. Technol., 211, No. 2, 275–284 (2011).

E. Yasa et аl., Rapid Prototyp. J., 17, No. 5, 312–327 (2011).

E. Yasa and J. Kruth, Adv. Product. Engin. & Manag., 6, No. 4, 259–270 (2011); [https://lirias.kuleuven.be/bitstream/123456789/332611/2/APEM6-4_259-270.pdf].

V. V. Smirnov and E. F. Shaikhutdinova, Vestn. KGТU im. Тupoleva, No. 2-2, 90–94 (2013).

L. S. Baeva and A. A. Marinin, Herald of Bauman Moscow State Technical University, 17, No. 1, 7–12 (2014).

Additive Manufacturing (2016) [http://www.arcam.com/technology/additive-manufacturing/]; Submission date 05.31.2016.

N. N. Koval and Yu. F. Ivanov, Russ. Phys. J. 51, No. 5, 505–516 (2008).

A. D. Teresov, N. N. Koval, and E. A. Petrikova, Izv. Vyssh. Uchebn. Zaved. Fizika, 59, No. 9/2, 264–266 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 8, pp. 93–97, August, 2017.

Rights and permissions

About this article

Cite this article

Teresov, A.D., Ivanov, Y.F., Petrikova, E.A. et al. Structure and Properties of VT6 Alloy Obtained by Layered Selective Sintering of a Powder. Russ Phys J 60, 1367–1372 (2017). https://doi.org/10.1007/s11182-017-1223-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-017-1223-3