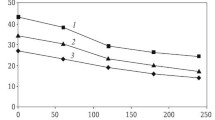

The microstructure of corundum ceramics based on powders with a varying grain size has been investigated. Both commercial alumina powders and those fabricated by denitration of aluminum salts in a high-frequency discharge plasma were used. An increase in the plasma-chemical Al2O3 powder content in the sample was found to change the pore structure of the corundum ceramics from a high-porosity ceramic skeleton with a well-developed system of channel-forming pores to ceramics with isolated pores. The change in the pore structure was observed for 50% porosity and caused an increase in the level of crystal lattice microdistortions. An increase in the sintering temperature from 1200 to 1650°C is shown to be responsible for a two-fold increase in the average crystallite size and for annealing of lattice defects along grain boundaries.

Similar content being viewed by others

References

E. S. Lukin, A. L. Kuteinikova, and N. A. Popova, Steklo Keram, No. 3, 17–18 (2003).

E. S. Lukin, N. A. Makarov, A. I. Kozlov, et al., Ibid., No. 10, 27–31 (2008).

E. M. Tomilina, O. V. Pronina, E. S. Lukin, and G. G. Kagramanov, Ibid., No. 6, 23–24 (2000).

T. P. Salikhov, V. V. Kan, E. M. Urazaeva, et al., Ibid., No. 8, 28–31 (2008).

B. L. Krasnyi, V. P. Tarasovskii, A. B. Krasnyi, and A. L. Kuteinikova, Ibid., No. 6, 18–21 (2009).

S. N. Kulkov, V. I. Maslovskii, S. P. Buyakova, and D. S. Nikitin, Tech. Phys., 47, No. 3, 320–324 (2002).

S. P. Buyakova and S. N. Kulkov, Ogneupory Tekhn. Keram., No. 11, 6–11 (2005).

Yu. L. Krasulin, Porous Structural Ceramics [in Russian], Metallurgiya, Moscow (1980).

Man F. Yan, J. Am. Ceram. Soc., 21, 53–72 (1987).

M. V. Grigoriev and S. N. Kulkov, Zh. Sib. Fed. Univ., Tekhn. Tekhnol., 3, No. 2, 294–300 (2009).

Ya. O. Umanskii, Yu. A. Skakov, A. N. Ivanov, et al., Crystallography, Roentgenography and Electronic Microscopy [in Russian], Metallurgiya, Moscow (1982).

A. Guinier, Theorie et Technique de la Radiocristallographie, Dunod, Paris (1956).

A. I. Gusev, Phys. Usp., 41, No. 1, 49–76 (1998).

P. V. Korolev and S. N. Kulkov, Perspektiv. Mater., No. 2, 55–61 (1998).

V. N. Antsiferov, G. V. Bobrov, L. K. Druzhinin, et al., Powder Metallurgy and Sprayed Coatings [in Russian], Metallurgiya, Moscow (1987).

P. Kofstad, Nonstoichiometry, Diffusion and Electrical Conductivity in Binary Metal Oxides, Wiley, N. Y. (1972).

S. N. Kulkov, J. Tomaś, and S. P. Buyakova, Tech. Phys. Lett., 32, No. 1, 73–75 (2006).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Izvestiya Vysshikh Uchebnykh Zavedenii, Fizika, No. 12, pp. 77–82, December, 2010.

Rights and permissions

About this article

Cite this article

Grigoriev, M.V., Kulkov, S.N. Fine crystal structure of porous corundum ceramics. Russ Phys J 53, 1305–1311 (2011). https://doi.org/10.1007/s11182-011-9565-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11182-011-9565-8