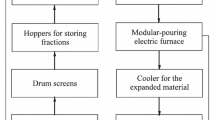

A new modification of electric modular firing furnaces for heat treatment of vermiculite with firing module curved surfaces is considered. The basic designs of such furnaces consist of three or two flat modules installed at an angle to each other for pouring material from one module to another and firing in a thermal field created by electric heaters.With the same length of curved module refractory base the heat treatment time increases by 23%, and the exit velocity of the expanded vermiculite grains decreases to 0, 6 – 0, 65 m/sec, which is enough so that all particles, regardless of size, do not settle at the module outlet and do not form blockages. Increasing firing duration does not reduce furnace productivity, but it reduces the specific energy content of the process. Energy consumption and energy intensity of vermiculite firing are reduced by 13 %, but the module design is not optimal. Optimization of the size and shape of modules to increase furnace unit energy efficiency is a task for subsequent research.

Similar content being viewed by others

References

A. I. Nizhegorodov, “development of the concept of power-engineering units for firing vermiculite concentrates based upon electric modular-delivery furnaces,” Ogneupory Tekhn. Keram., No. 1/2, 48 – 55 (2014).

A. I. Nizhegorodov, “Technological and energy capabilities of electric two-module pouring furnaces with upper heating system,” Refract. Ind. Ceram., 61(3), 260 – 266 (2020).

S. S. Kutateladze, Heat Transfer and Hydrodynamic Resistance: Reference [in Russian], Énergoatomizdat, Moscow (1990).

A. I. Nizhegorodov, Technology and Equipment for Processing Vermiculite: Optimum Fractionation, Electric Firing, Enrichment [in Russian], Izd. IrGTU, Irkutsk (2011).

R. Ya. Akhtyamov, Vermiculite—raw material for producing refractory heat insulation materials,” Ogneupor. Tekhn. Keram., No. 1/2, 59 – 64 (2009).

A. V. Zvezdin, T. B. Bryanskikh, and A. I. Nizhegorodov, “Analytical model of absorption reflection properties of vermiculite under thermal radiation conditions,” Refract. Ind. Ceram., 58(1), 19 – 24 (2017).

F. Kreit and U. Black, Bases of Heat Transfer [Russian translation] Mir, Moscow (1983).

B. M. Yavorskii and A. A. Detlaf, Physics Handbook for Engineers and High School Students [in Russian], Nauka, Moscow (1968).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 12, pp. 22 – 28, December, 2022

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Nizhegorodov, A.I., Gavrilin, A.N. & Moizes, B.B. Development of an Electric Furnace for Heat Treatment of Vermiculite with Firing Module Curved Surfaces. Refract Ind Ceram 63, 610–615 (2023). https://doi.org/10.1007/s11148-023-00778-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-023-00778-1