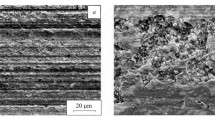

The relationship between grinding regime parameters and the nature of friction interaction and tribological properties of a hybrid friction pair of steel ball-sample Y-TZP ceramic at the run-in stage is established. It is shown that the mechanism of influence of ceramic component manufacturing technology on friction interaction conditions, friction coefficient, width and condition of friction track, is based on changes in roughness and morphology of a ground ceramic surface after finish machining. Engineering recommendations for manufacture of ceramic components for a hybrid friction pair are developed using the features revealed.

Similar content being viewed by others

References

H. C. Garg, V. Kumar, H. B. Sharda, “Performance of slot-entry hybrid journal bearings considering combined influences of thermal effects and non-Newtonian behavior of lubricant,” Tribology International, 43(8), 1518 – 1531 (2010).

GOST R 50740–95 Tribological requirements and indices. Provision principles. General assumptions. Date of introduction 01-01-1996.

V. V. Kuzin, S. Y. Fedorov, V. L. Reutov, and V. V. Koshcheev, “Service-induced damages of the ceramic thrust bearing pivot in the seal section of electrical centrifugal pump system,” Refract. Ind. Ceram., 59(5), 564 – 568 (2019).

I. Birkby, P. Harrison, and R. Stevens, “The effect of surface transformation on the wear behavior of zirconia TZP ceramics,” J. Eur. Ceram. Soc., 5(1), 37 – 45 (1989).

S. Novak, G. Drazic, M. Kalin, “Structural changes in ZrO2 ceramics during sliding under various environments,” Wear, 259(1 – 6), 562 – 568 (2005).

A. Tucci and L. Esposito, “Microstructure and tribological properties of ZrO2 ceramics,” Wear, 172(2), 111 – 119 (1994).

M. Woydt, J. Kadoori, K.-H. Habig, and H. Hausner, “Unlubricated sliding behavior of various zirconia-based ceramics,” J. Eur. Ceram. Soc., 7(3), 135 – 145 (1991).

V. V. Kuzin, S. Yu. Fedorov, and A. E. Seleznev, “Effect of conditions of diamond grinding on tribological behavior of alumina-based ceramics,” Journal of Friction and Wear, 37(4), 371 – 376 (2016).

M. A. Markov, D. V. Snimshchikov, and A. BV. Krasikov, “Tribological rapid investigation of wear resistance for ceramic based on Al2O3 with SiC fibers in a friction pair with steel,” Voprosy Materialovedenie, No. 3(87), 97 – 103 (2016).

K. Madhav Reddy, Amartya Mukhopadhyay. Bikramjit Basu, “Microstructure-mechanical tribological property correlation of multistage spark plasma sintered tetragonal ZrO2,” J. Eur. Ceram. Soc., 30(16), 3363 – 3375 (2010).

B. Venkata Manoj Kumar, Won-Sik Kim, Seong-Hyeon Hong, Hung-Tak Bae, and Dae-Soon Lim,” Effect of grain size on wear behavior in Y-TZP ceramics,” Mater. Sci. Eng., A, 527(3), 474 – 479 (2010).

Pavol Hvizdoš, Álvaro Mestra, Marc Anglada, “Effect of heat treatment on wear damage mechanisms in 3Y-TZP ceramics,” Wear, 269(1/2), 2 – 30 (2010).

Fei Zhang, Benedikt C. Spies, Jef Vleugels, et al., “High-translucent yttria-stabilized zirconia ceramics are wear-resistant and antagonist friendly,” Dental Materials, 35(12), 1776 – 1790 (2019).

Jessica Schiltz, Andrew Rosenberger, Todd Render, et al., “Wear of structural oxide ceramics produced through additive manufacturing,” Procedia Manufacturing, 34, 780 – 788 (2019).

Chen Lu, Yunlong Ai,Weihua Chen, et al., “Microstructure and tribological properties of ZrO2(Y2O3)–Al2O3–graphite composite ceramic fabricated by milling with graphite balls,” Tribology International, 140, 105874 (2019).

Walter Harrer, Marco Deluca, and Roger Morrell, “Failure analysis of a ceramic ball race bearing made of Y-TZP zirconia,” Engineering Failure Analysis, 36, 262 – 268 (2014).

Fernando Rodríguez-Rojas, Rafael Cano-Crespo, Oscar Borrero-López, et al., “Effect of 1-D and 2-D carbon-based nanoreinforcements on the dry sliding-wear behavior of 3Y-TZP ceramics,” J. Eur. Ceram. Soc., 41(6), 3595 – 3602 (2021).

G. K. R. Pereira, S. Fraga, A. F. Montagner, et al., “The effect of grinding on the mechanical behavior of Y-TZP ceramics: A systematic review and meta-analyses,” Journal of the Mechanical Behavior of Biomedical Materials, 63, 417 – 442 (2016).

M. Buciumeanu, J. R. C. Queiroz, A. E. Martinelli, et al., “The effect of surface treatment on the friction and wear behavior of dental Y-TZP ceramic against human enamel,” Tribology International, 116, 192 – 198 (2017).

G. K. R. Pereira, M. Amaral, R. Simoneti, et al., Effect of grinding with diamond disc and -bur on the mechanical behavior of a Y-TZP ceramic,” Journal of the Mechanical Behavior of Biomedical Materials, 37, 133 – 140 (2014).

Gabriela Scatimburgo Polli, Gabriel Rodrigues Hatanaka, Filipe de Oliveira Abi-Rached, et al., “Fatigue behavior and surface characterization of a Y-TZP after laboratory grinding and regeneration firing,” Journal of the Mechanical Behavior of Biomedical Materials, 88, 305 – 312 (2018).

Shuai Yan, Chibin Wei, Hongbo Zou, et al., “Fabrication and tribological characterization of laser textured engineering ceramics: Si3N4, SiC and ZrO2,” Ceram. Int., 47(10), 13789 – 13805 (2021).

M. Antonov, H. Afshari, J. Baronins, et al., “The effect of temperature and sliding speed on friction and wear of Si3N4, Al2O3, and ZrO2 balls tested against AlCrN PVD coating,” Tribology International, 118, 500 – 514 (2018).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Correlation of diamond grinding regime with surface condition of ceramic based on zirconium dioxide,” Refract. Ind. Ceram., 57(6), 625 – 630 (2017).

V. V. Kuzin, S. Yu. Fedorov, S. N. Grigor’ev, “Level of Y-TZP ceramic specimen edge defects after diamond machining,” Refract. Ind. Ceram., 58(4), 415 – 417 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 1, pp. 48 – 54, January, 2022.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kuzin, V.V., Grigor’ev, S.N. & Fedorov, S.Y. Engineering Provision of Tribological Characteristics of a Y-TZP-Ceramic-Hardened Steel Hybrid Friction Pair. Refract Ind Ceram 63, 49–54 (2022). https://doi.org/10.1007/s11148-022-00679-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-022-00679-9