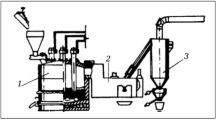

The article analyzes samples of chamotte refractory after service in the shaft and in the crucible of a coke gas cupola furnace during melting of cast iron with spheroidal graphite using carbon waste from the electrolysis production of aluminum as a reducing agent. It was established that the products acquire a pronounced zonal nature in service. After service in a shaft, products have a complex compaction property associated with the depth of penetration of volatile components of the charge. After service in the crucible of a coke gas cupola furnace, refractories contain a melted crust of the working zone formed in contact with the cast iron melt; working zone formed as a result of impregnation of cast iron and/or slag with melt; the least changed transition and impregnated (weakly metamorphosed) zones which structure differs little from the structure of the original refractory.

Similar content being viewed by others

References

V. M. Grigoriev, Ya. V. Zhatchenko, “Cast iron remains a promising alloy for brake pads, Transp. Aziat.-Tikhookeans. Reg., 6(1), 12 – 15 (2016).

V. M. Kolokoltsev, E. V. Petrochenko, “Structure feature and properties of high-alloy white irons” Vest. Nosov Magnitogorsk State Tech. Univ., 45(5), 5 – 8 (2013).

P. K. Sain, C. P. Sharma, and A. K. Bhargava, “Microstructure aspects of a newly developed, low cost, corrosion-resistant white cast iron,” J. Metall. Mater. Trans. A, 44F, 1665 – 1671 (2013).

J. Yoganandh, S. Natarjan, and S. P. Kumaresh Babu, “Wear behavior of nickel-based high alloy white cast iron under mining conditions using orthogonal array,” Erosive J. Mater. Eng. Perform., 22(9), 2534 – 2540 (2013).

B. Abbasi-Khazaei, S. Ghaderi, “A novel process in semi-solid metal casting,” J. Mater. Technol., 28(10), 946 – 950 (2012).

M. A. Kobozev, N. A. Maryin, R. V. Pavlyuk, et al., “Indicators of relative wear resistance of the main friction pairs of serial and modernized vacuum pumps of plate type,” Nauchn. Obozren., No. 22, 95 – 99 (2016).

L. V. Kostyleva, D. S. Gapich, V. A. Motorin, et al. “Increase in the wear resistance of soil-cultivating working bodies due to structuring of high-carbon alloys,” Izv. Nizhnevolzh. Agrouniv. Kompleksa: Nauka Vyssh. Prof. Obrazov., 51(3), 283 – 291 (2018).

V. K. Afanasyev, M. V. Popova, A. P. Chernysh, et al., “Some results and prospects for the development of unalloyed high-strength cast iron,” Metallurg. Mashinostr., No. 4, 11 – 16 (2020).

V. K. Afanasyev, S. A. Gladyshev, L. A. Godik, et al., Blast-Furnace Iron is Metal of the Future [in Russian],”ed. V. K. Afanasyev, Kuzbassvuzizdat, Kemerovo (2005).

A. P. Trukhov, Yu. A. Sorokin, M. Yu. Ershov, et al., Technology of Foundry Production: Casting in Sand Molds, a textbook for universities [in Russian], ed. A. P. Trukhov, IC Akademiya, Moscow (2005).

V. I. Matyukhin, A. V. Matyukhina, Calculation and Design of a Cupola Complex for Cast Iron Melting [in Russian], FGAOU VO UrFU, Yekaterinburg (2015).

A. A. Cherny, Gas Cupolas and Energy-Saving Processes of Cast Iron Melting in them, study guide [in Russian], Penzen. Gos. Univ., Penza (2009).

Yu. S. Sukharchuk, A. L. Yudin, Cast Iron Melting in Cupolas [in Russian], Mashinostroenie, Moscow (1989).

Metallurgical Bulletin. Electronic resource. Access mode: https://www.metaltorg.ru/metalcatalog/metallurgicheskoyesyryeipolufabrikaty/koks/coke. Date of reference 03/01/2021.

Metallurgical Bulletin. Electronic resource. Access mode: https://www.metaltorg.ru/metalcatalog/metallurgicheskoyesyryei-polufabrikaty/koksuyushchiisyaugol/koksuyushchiisyaugol/. Date of reference 03/01/2021.

O. T. Ibraeva, I. K. Ibraev, “Improving environmental cleanliness and reducing the resource intensity of metallurgical production,” Sci. Time, No. 10, 146 – 159 (2014).

I. K. Ibraev, O. Artybekov, and A. A. Artybekova, “On the study of the influence of various carbonaceous fuels on the agglomeration process,” Tekhnol. Proizvod. Metallov Vtorich. Mater., 19(1), 45 – 52 (2011).

I. K. Ibraev, O. T. Ibraeva, and A. Z. Isagulov, Main directions of using wastes from coal flotation in metallurgical production, Tr. Innovats. Yevraziysk. Univ., 24(2/3), 48 – 54 (2006).

I. K. Ibraev, O. T. Ibrayeva, “Research and development of technology for utilization of carbon-containing sludge in metallurgical production,” Sci. Time, No. 5, 72 – 90 (2014).

I. K. Ibraev, O. T. Ibrayeva, “Use of coal refining waste in metallurgical production,” Proceedings of the Congress with International Participation and Elements of the School of Young Scientists “Fundamental Research and Applied Development of the Processes of Processing and Disposal of Technogenic Formations”(Technogen-2014), Yekaterinburg, June 2 – 6, 359 – 362 (2014).

V. Yu. Bazhin, A. A. Vlasov, and R. K. Patrin, “Disposal of technogenic waste of electrolysis aluminum production,” Bezopas. Zhizned., No. 9, 18 – 21 (2010).

R. K. Patrin, V. M. Sizyakov, and V. Yu. Bazhin, “Prospects for pyrometallurgical processing of technogenic waste from aluminum production,” Izv. Vuzov. Tsvetn. Metallurg., No. 6, 61 – 63 (2013).

S. I. Ivankov, A. V. Troitsky, “Patented technological solutions for processing and disposal of large-tonnage wastes of aluminum production,” Nauchnyye Tekhnich. Aspekty Okhr. Okruzhayush.. Sredy, No. 3, 38 – 102 (2020).

N. V. Golovnykh, “Strengthening of technological materials and recycling of wastes of lining of aluminum production electrolysis cells,” Ekolog. Promyshl. Proizvod., No. 4, 47 – 52 (2010).

A. V. Ermienko, “Problems of production and consumption waste at the Kazakhstan Electrolysis Plant (Pavlodar),” Agrarnyy Vest. Urala, 57(3), 95 – 97 (2009).

A. N. Baranov, N. V. Nemchinova, V. V. Anikin, et al., “Recycling and disposal of fluorine-carbon-containing wastes of aluminum production,” Vestnik IrGTU, 61(2), 63 – 70 (2012).

V. G. Terentyev, R. M. Shkolnikov, I. S. Grinberg, et al., Aluminum Production [in Russian], MANEB, St. Petersburg (2001).

C. R. Hubbard, E. H. Evans, and D. K. Smith, “The reference intensity ratio for computer simulated powder patterns,” J. Appl. Cryst., 169(9), 169 – 174 (1976).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 9, pp. 3 – 8, September, 2021.

Rights and permissions

About this article

Cite this article

Isagulov, A.Z., Kashcheev, I.D., Sidorina, E.A. et al. Behavior of the Fireclay Lining of a Coke Gas Cupola Furnace When Melting Cast Iron Using Anode Scrappage in Electrolysis Production. Part 1. Refract Ind Ceram 62, 492–496 (2022). https://doi.org/10.1007/s11148-022-00632-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-022-00632-w