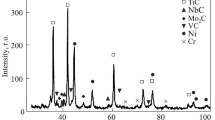

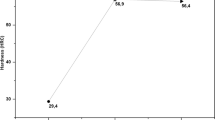

A new cermet material based on titanium carbide with a complex binder consisting of nichrome and nickel, additionally hardened with chromium carbide and a solid solution of chromium in titanium carbide, has been obtained. The influence of the technological parameters of the SHS-extrusion method (the delay time before the application of pressure, the pressing pressure, the speed of the press plunger movement) on the length of the extruded rod is studied, the optimal parameters are found. The microstructure and phase composition of the obtained material was investigated, the physical and mechanical characteristics were measured, and a comparison with analogues was given. It is shown that the microstructure, phase composition, and crystal lattice parameters of the phases do not change depending on the diameter of the extruded rod.

Similar content being viewed by others

References

C. M. Franco- Rendon, H. Leon-Henao, A. D. Bedoya-Zapata, et al., “Failure analysis of fillet welds with premature corrosion in 316L stainless steel slide gates using constitution diagrams,” UIS INGENIERIAS, 19, 141 – 148 (2020).

H. J. Lee, B. G. Thomas, S. H. Kim, “Thermal stress cracking of slide-gate plates in steel continuous casting,” Metall. Mater. Trans. B., 47, 1453 – 1464 (2016).

J. H. Lee, J. C. Ge, J. H. Song, “Study on burr formation and tool wear in drilling CFRP and its hybrid composites,” Appl. Sci.-Basel., 11, Article No. 384 (2021).

Y. B. Tian, L. G. Li, J. G. Han, et al., “Development of novel high-shear and low- pressure grinding tool with flexible composite,” Mater. Manuf. Process., 36, 479 – 487 (2020).

Z. L. Zhu, D. Buck, X. L. Guo, et al., “High-quality and high-efficiency machining of stone-plastic composite with diamond helical cutters,” J. Manuf. Process., 58, 914 – 922 (2020).

H. C. Mohring, M. Muller, J. Krieger, et al., “Intelligent lightweight structures for hybrid machine tools,” Prod. Eng.-Res. Dev., 14, 583 – 600 (2020).

S. Asnaashari and M. Ghambari, “Preparation and characterization of composite WC/Co through rapid omnidirectional compaction,” J. Alloys Compd., 859, Article No. 157764 (2021).

A. Laptiev, “Some trends in improving WC–Co hardmetals. II. Functionally graded hardmetals,” Powder Metall. Met. Ceram., 58, 170 – 183 (2019).

V. Mohanavel, S. Suresh Kumar, T. Sathish, et al., “Microstructure and mechanical properties of hard ceramic particulate reinforced AA7075 alloy composites via liquid metallurgy route,” Mater. Today: Proceed., 5, 26860 – 26865 (2018).

A. M. Stolin and P. M. Bazhin, “SHS extrusion: an overview,” Int. J. Self Propag. High Temp. Synth., 23, 65 – 73 (2014).

W. Zhang, M. L. Sui, Y. Z. Zhou, et al., “Evolution of microstructure in TiC/NiCr cermet induced by electropulsing,” J. Mater. Res., 18, 1543 – 1550 (2003).

J. L. Li, Z. L. Xu, Y. J. Li, et al., “Intergranular passivation of the TiC coating for enhancing corrosion resistance and surface conductivity in stainless-steel bipolar plates,” J. Mater. Sci., 56, 8689 – 8703 (2021).

V. V. Akimov, A. F. Mishurov, and E. V. Akimova, “Heat resistance of tungsten-free TiC- TiNi hard alloys in dependence on volumetric compound of composition at heating up to high temperatures,” Izvestiya. Ferrous Metallurgy, 59, 688 – 691 (2016).

R. Saeedi, R. Razavi, S. Bakhshi, et al., “Optimization and characterization of laser cladding of NiCr and NiCr–TiC composite coatings on AISI 420 stainless steel,” Ceram. Int., 47, 4097 – 4110 (2021).

This work was financed by the grant of the President of the Russian Federation for state support of young Russian scientists — Doctors of Sciences No. MD-2909.2021.4.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 4, pp. 34 – 37, April 2021.

Rights and permissions

About this article

Cite this article

Antipov, M.S., Chizhikov, A.P., Konstantinov, A.S. et al. Sintered Material Based on Titanium Carbide to Increase the Service Life of Slide Gates. Refract Ind Ceram 62, 208–211 (2021). https://doi.org/10.1007/s11148-021-00584-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00584-7