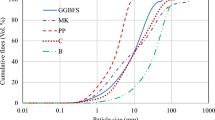

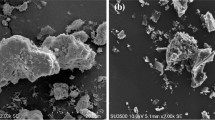

The object of research is a ceramic brick taken from the wall of the Nativity Church (Rozhdestveno village, Samara region). The oxide chemical composition showed an increased content of Fe2O3 (3.45%) and alkalis (4.59%) in the material samples, which ensures the formation of a liquid phase already at 950°C. Element-by-element chemical analysis revealed an increased content of CaO (3.75%) in the samples, which contributes to the formation of anorthite that increases the products strength. The increased content of carbon in the samples (15.2%) indicates the introduction of fuel into the raw material, which ensures uniform sintering of the ceramic material inside the sample. The results of x-ray phase analysis and IR spectroscopic analysis of the samples composition confirmed that the increased content of calcium in them contributes to the formation of anorthite.

Similar content being viewed by others

References

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Relationship of phase and chemical compositions with the durability of the ceramic material of the fortress wall of Thessaloniki (Greece) aged more than 1000 years,” Nov. Ogneupory, No. 9, 56 – 59 (2020).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Relationship of phase and chemical compositions with the durability of the ceramic material of the Barcelona Catholic Cathedral aged more than 600 years,” Steklo Keram., No. 1, 37 – 41 (2020).

V. Z. Abdrakhimov, “Relationship of the phase composition with durability of ceramic bricks aged more than 600 years on the example of the Ipatiev Monastery,” Steklo Keram., No. 3, 29 – 33 (2013).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Study of the phase composition and porosity structure of a ceramic material that is more than 400 years old (Spain),” Refract. Ind. Ceram., 61(4), 404 – 406 (2020).

V. Z. Abdrakhimov, “Phase composition of clinker bricks based on waste from nonferrous metallurgy of Eastern Kazakhstan,” Khim. Tekhnol., No. 9, 406 – 413 (2019).

V. Z. Abdrakhimov and E. S. Abdrakhimova, “Study of the phase composition of ceramic materials based on aluminum-containing waste from non-ferrous metallurgy, chemical and petrochemical industries,” Nov. Ogneupory, No. 1, 3 – 9 (2015).

A. K. Kairakbaev, V. Z. Abdrakhimov, and E. S. Abdrakhimova, “Structure of porosity and technical properties of clinker materials based on waste from non-ferrous metallurgy of Eastern Kazakhstan,” Steklo Keram., No. 2, 45 – 50 (2020).

V. Z. Abdrakhimov and E. S. Abdrakhimova, “Structure of porosity of a porous filler based on burnt rock, burnt clay and liquid glass compositions,” Khim. Tekhnol., 20(8), 354 – 360 (2019).

E. S. Abdrakhimova and V. Z. Abdrakhimov, “Chemical, phase compositions and porosity structure of bricks of the White Tower (Greece) aged more than 450 years,” Steklo Keram., No. 4, 40 – 43 (2019).

A. K. Kairakbaev, V. Z. Abdrakhimov, and E. S. Abdrakhimova, “Research of iron oxides in acid-resistant ceramic materials based on industrial waste by the method of Moessbauer spectroscopy,” Nov. Ogneupory, No. 3, 56 – 60 (2020).

V. Z. Abdrakhimov and E. S. Abdrakhimova, “Oxidation processes in the firing of porous filler based on oil production wastes and intershale clay,” Theor. Found. Chem. Eng., 54(4), 750 – 755 (2020).

V. Z. Abdrakhimov, “Phase composition of clinker bricks based on waste from nonferrous metallurgy of Eastern Kazakhstan,” Khim. Tekhnol., No. 9, 406 – 413 (2019).

B. N. Vinogradov, Petrography of Artificial Porous Fillers [in Russian], Stroiizdat, Moscow (1972).

S. T. Suleimenov, Physico-Chemical Processes of Structure Formation in Building Materials and Industrial Mineral Waste [in Russian], Manuskript, Moscow (1996).

T. I. Litvinova, V. P. Pirozhkova, and A. K. Petrov, Petrography of nonmetallic inclusions [in Russian], Metallurgiya, Moscow (1972).

S. Zh. Saibulatov, “Investigation of the effect of ash composition on phase transformations in ash-ceramics,” Kompleks. Ispol’z. Mineral. Syr’ya, No. 11, 78 – 81 (1985).

E. S. Abdrakhimova, A. V. Abdrakhimov, and V. Z. Abdrakhimov, “Polymorphic transformations of SiO2 in clay materials of various chemical and mineralogical composition,” Materialovedenie, No. 7, 35 – 41 (2002).

V. V. Shevando, E. V. Vdovina, and A. V. Abdrakhimov, “Polymorphic transformations of quartz in clays of various chemical and mineralogical composition,” Izv. VUZov, Stroit., No. 6, 40 – 47 (2007).

V. F. Pavlov, “Features of the transformation of silica contained in clays,” Trudy NIIstroikeram., 38, 3 – 11 (1973).

G. V. Kukolev, Chemistry of Silicon and Physical Chemistry of Silicates [in Russian], Vysshaya Shkola, Moscow (1966).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 3, pp. 59 – 63, March, 2021.

Rights and permissions

About this article

Cite this article

Abdrakhimova, E.S., Abdrakhimov, V.Z. Relationship of Phase and Chemical Compositions with Durability of Ceramic Bricks Aged More Than 170 Years (Nativity Church, Samara Region). Refract Ind Ceram 62, 185–188 (2021). https://doi.org/10.1007/s11148-021-00580-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00580-x