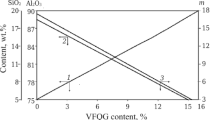

A comprehensive analysis of the quality parameters of fused cast aluminum-zirconium-silicate (AZS) refractories for glass furnaces has been carried out. It was shown that the assessment of the quality of AZS refractories based on the content of ZrO2 and density does not fairly reflect their performance characteristics. Of fundamental importance are the chemical composition and behavior of the glassy phase, which determine the volume and exudation onset temperature. The most important conditions for obtaining high-quality AZS refractories, characterized by a glassy phase melt-out volume of 2 – 3% and melt-out onset temperature above 1,400°C, include the use of an oxidative melting technology and the content of impurities in the chemical composition of the refractory of no more than 0.25 – 0.30%. The service conditions of AZS refractories in the melting tank and the working space of glass-melting furnaces have been formulated. Their effect on the exudation process behavior, corrosion resistance of the refractories, and formation of glass defects was shown.

Similar content being viewed by others

References

V. Ya. Dzyuzer, “Electrofused AZS refractories for high-capacity glass-founding furnaces,” Refract. Ind. Ceram., 54(4), 304 – 306 (2013).

B. Ýzmirlioðlu and S. Yýlmaz, “Glass melting furnace refractories and refractory related defects,” Journal of Chemical Technology and Metallurgy, 50(4), 404 – 410 (2013).

V. Ya. Dzyuzer, “Use of refractories in the melting tank of a high-production-capacity glass melting furnace,” Refract. Ind. Ceram., 59(5), 435 – 440 (2019).

GOST 23053–78, Baddeleyite-corundum refractories for the glass-making furnaces. Specifications.

STANDART JC 493–2015. Fused cast AZS refractories for glass furnace: ICS 81.080 Q44, The general specification of building materials in China.

SEFPRO. Products and services for the glass industry: http://www.ru.sefpro.com.

RHI GLAS. Feuerfeste Werkstoffe für die Glasindustrie: http://www.rhi.com.

MOTIM. Fused Cast Refractories Ltd: http://www.motim.hu.

ZIRCOR Electrofusion s. a. AZS Fused Cast Refractories: http://www.zircor.com.

Luoyang Dayang Refractory: http://www.dyrefractory.com.

JSC “Podol’skiye Ogneupory”: info@podolskrefractories.com.

O. N. Popov, P. T. Rybalkin, V. A. Sokolov, and S. D. Ivanov, Production and Use of Fused Cast Refractories [in Russian], Metallurgiya, Moscow (1985).

ASTM C 621–09 (2018), Standard test method for isothermal corrosion resistance of refractories to molten glass.

D. Walrod, “How furnace operation affects AZS glassy phase exudation,” Glass Ind., 71(8), 19 – 27 (1990).

R. Heidrich and A. Gupta, “Fused cast AZS glassy phase exudation: intrinsic or pathologic property?” RHI Bulletin, No. 2, 24 – 28 (2011).

B. Fleischmann, “Glassy phase segregation from AZS blocks,” Glass Science and Technology, 78(6), 295 – 300 (2005).

J. Canaguier, “How to reduce corrosion on fused-cast AZS,” 16th Conference on the Electric Glass Melting, Prague, Czech Glass Society (2016).

ASTM C 1223–19, Standard test method for testing of glass exudation from azs fusion-cast refractories.

https://www.diytrade.com/china/pd/9843042/AZS_refractory_Glass_refractory.html.

K. Selkregg and A. Gupta, “Investigation of defects in high-quality glasses,” 64th Conference on glass problems: ceramic engineering and science proceedings, 25(1), 13 – 32 (2008).

F. A. G. van Dijk, Glass Defects Originating from Glass Melt/Fused Cast AZS Refractory Interaction, Eindhoven, Technische Universitet Eindhoven (1994).

P. Simurka, J. Kraxner, P. Vrabel, and T. Pauco, “Corrosion of AZS refractories – source of defects in tableware glass,” 76th Conference on Glass Problems (2016), pp. 89 – 102.

K. Selkregg, “Characterization of glass defects arising in today’s evolving glass technologies,” RHI Bulletin, No. 2, 19 – 26 (2014).

D. A. Walrod, “Study of the driving force behind AZS glassy phase exudation,” Proceedings of the 49th conference on glass problems, Ceramic Engineering and Science Proceedings, 10(3/4), 338 – 347 (2008).

V. A. Dziuser and V. S. Shvydkii, Design of Energy-efficient Glass-melting Furnaces [in Russian], Teplotekhnik, Moscow (2009).

V. Ya. Dzyuzer and V. S. Shvydkii, “Boundary conditions for designing the lining of a glass-founding furnace with innovative parameters to improve technical efficiency,” Refract. Ind. Ceram., 56(6), 597 – 600 (2016).

H. Bach, F. G. K. Baucke, R. Brueckner, et al., Types of defects in Glass Production, ed. by G. Jebsen-Marwedel and R. Brueckner [in Russian], abbreviated transl. from German by L. G. Weiburt, et al., ed. by N. N. Rokhlin, Stroyizdat, Moscow (1986).

N. A. Ozerov, B. A. Semenov, and V. N. Lunkin, “Mathematical modeling of high-temperature corrosion of melting tank refractories of glass-melting furnaces,” Izv. Vuzov, Problemy Energetiki, No. 7/8, 88 – 93 (2010).

R. Heidrich, A. Gupta, S. Postrach, and M. Dietrich, “REFEL 1616ULX – an ultra-low exudation fused cast product for the super-structure of glass melting furnaces,” RHI Bulletin, No. 2, 16 – 17 (2014).

I. Cabodi, M. Gaubil, and C. Morand, “ER 2001 SLX – very low exudation AZS product for glass furnace superstructures,” Refractories Worldforum, 3(2), 83 – 86 (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 4, pp. 3 – 9, April, 2021.

Rights and permissions

About this article

Cite this article

Dzyuzer, V.Y. Analysis of Quality Parameters of Fused Cast AZS Refractories for Glass-Making Furnaces. Refract Ind Ceram 62, 123–129 (2021). https://doi.org/10.1007/s11148-021-00570-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-021-00570-z