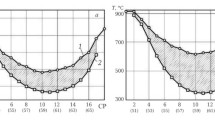

A coating for a Si3N4 ceramic end mill was selected based on the analysis of the results of numerical simulation of the stress-strain behavior of its cutting edge. It was found that the TiC coating is more effective than TiN coating, and reduces the temperature and stresses of the cutting edge of the mill under the transient thermoelastic conditions. This is critical for reducing the intensity of micro-chipping of ceramic material during operation.

Similar content being viewed by others

References

V. V. Kuzin, S. N. Grigoriev, and M. A. Volosova, “Design of the ceramic-bladed and milling cutters with regard for their stress-strain state for the innovation technological processes. Choice of ceramics. Part 1,” Refract. Ind. Ceram., 59(5), 558 – 563 (2019).

V. V. Kuzin and S. N. Grigoriev, “Design of the ceramic-bladed and milling cutters with regard for their stress-strain state for the innovation technological processes. Choice of ceramics. Part 2,” Novye Ogneupory, No. 4, 65 – 69 (2019).

V. V. Kuzin and S. N. Grigoriev, “Design of the ceramic-bladed and milling cutters with regard for their stress-strain state for the innovation technological processes. Choice of ceramics. Part 3,” Novye Ogneupory, No. 6, 46 – 49 (2019).

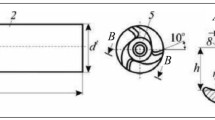

V. A. Grechishnikov, S. N. Grigoriev, P. M. Pivkin, et al., “Development of an integral ceramic end mill design with toroidal shape of the cutting edge,” Stanki i Instrument (STIN), No. 7, 31 – 35 (2019).

S. N. Grigoriev, V. A. Grechishnikov, M. A. Volosova, et al., “Development of integrated end mills from cutting ceramics for machining workpieces from hard-to-cut materials,” Vestn. MGTU Stankin, No. 4, 87 – 93 (2018).

V. V. Kuzin, S. N. Grigoriev, S. Yu. Fedorov, et al., “Spark plasma sintering of Al2O3-ceramics ingots for small-sized end mills,” Novye Ogneupory, No. 11, 64 – 68 (2018).

V. V. Kuzin, M. A. Volosova, and S. Yu. Fedorov, “Wear of tools from nitride ceramics when machining nickel-based alloys,” Journal of Friction and Wear, 34(3), 199 – 203 (2013).

M. A. Volosova and V. V. Kuzin, “Regular features of wear of cutting plates from oxide and nitride ceramics,” Metal Science and Heat Treatment, 54(1/2), 41 – 46 (2012).

V. V. Kuzin, S. N. Grigoriev, and M. A. Volosova, “The role of the thermal factor in the wear mechanism of ceramic tools: Part 1. Macrolevel,” Journal of Friction and Wear, 35(6), 505 – 510 (2014).

V. V. Kuzin, S. N. Grigoriev, and M. A. Volosova, “The role of the thermal factor in the wear mechanism of ceramic tools: Part 2. Microlevel,” Journal of Friction and Wear, 36(1), 40 – 44 (2015).

V. Kuzin, S. Grigoriev, M. Volosova, et al., “Designing of details taking into account degradation of structural ceramics at exploitation,” Applied Mechanics and Materials, 752/753, 268 – 271 (2015).

V. V. Kuzin, S. N. Grigoriev, D. R. Burton, et al., “A new generation of ceramic tools,” Proc. of the 10th Int. Conf. Manuf. Res. (ICMR), 523 – 528 (2012).

V. V. Kuzin, S. I. Dosko, V. F. Popov, et al., “Tooling for high-speed cutting,” Russian Engineering Research, 25(9), 20 – 25 (2005).

V. V. Kuzin, Tools with Ceramic Cutting Inserts [in Russian], Yanus-K, Moscow (2006).

S. N. Grigoriev, V. I. Shalenkov, and V. V. Kuzin, “The automated system for calculating thermal strength of ceramic inserts,” Vestn. Mashinostr., No. 11, 26 – 31 (2011).

V. Kuzin and S. Grigoriev, “Method of investigation of the stress-strain state of surface layer of machine elements from a sintered nonuniform material,” Applied Mechanics and Materials, 486, 32 – 35 (2014).

V. Kuzin, S. Grigoriev, and M. Portnoi, “Effect of thermal loading on stresses in defective surface layer of ceramics,” Applied Mechanics and Materials, 827, 189 – 192 (2016).

S. Grigoriev, V. Kuzin, D. Burton, et al., “The stress-strained state of ceramic tools with coating,” Proc. of the 37th Int. MATADOR Conf., 181 – 184 (2013).

V. Kuzin, S. Grigoriev, and M. Fedorov, “Applications of multi-level method of stress-strain state analysis in ceramic tools design,” Applied Mechanics and Materials, 827, 173 – 176 (2016).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 68 – 72, November, 2019.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigoriev, S.N. & Volosova, M.A. Selecting a Coating for Ceramic End Mill Based on the Stress-Strain Behavior of its Cutting Edge. Part 1. Refract Ind Ceram 60, 599–602 (2020). https://doi.org/10.1007/s11148-020-00413-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-020-00413-3