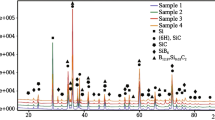

The results of studying the crack resistance of reaction-sintered B4C–SiC composite materials impregnated with liquid silicon with identification and fracture methods are presented. With an increase in the amount of B4C in the reaction-sintered material, its fragility increases. The crack resistance of the material can be increased from 3.40 to 4.02 MPa·m1/2 (when tested by different methods) by adding to the composite material up to 30 wt.% SiC. The material is destroyed mainly by the intercrystalline (intergranular) mechanism. Ceramics containing more than 90 wt.% B4C, is partially destroyed by the transcrystalline mechanism.

Similar content being viewed by others

References

S. N. Perevislov, P. V. Shcherbak, M. V. Tomkovich, “High-density boron carbide ceramics,” Refract. Ind. Ceram., 59(1), 32 – 36 (2018).

N. Cho, Z. Bao, and R. F. Speyer, “Density- and hardness-optimized pressureless sintered and post-hot isostatic pressed B4C,” J. Mater. Res., 20(8), 2110 – 2116 (2005).

X. Du, Z. Zhang, Y. Wang, et al., “Hot-pressing kinetics and densification mechanisms of boron carbide,” J. Am. Ceram. Soc., 98(5), 1400 – 1406 (2015).

S. Hayun, N. Frage, M. P. Dariel, et al., “Dynamic response of B4C –SiC ceramic composites,” Ceramic Armor and Armor Systems II, 178, 147 – 156 (2006).

C. P. Zhang, H. Q. Rue, X. Y. Yue, andW. Wang, “Studies on the RBBC ceramics fabricated by reaction bonded SiC,” Rare Metal Mat. Eng., 40, 536 – 539 (2011).

N. A. Golubeva, L. A. Plyasunkova, I. Yu. Kelina, et al., “Study of reaction-bonded boron carbide properties,” Refract. Ind. Ceram., 55(5), 414 – 418 (2015).

M. P. Dariel and N. Frage, “Reaction bonded boron carbide: recent developments,” Adv. Appl. Ceram., 111(5/6), 301 – 310 (2012).

S. N. Perevislov, P. V. Shcherbak, and M. V. Tomkovich, “Phase composition and microstructure of reaction-bonded boron-carbide materials,” Refract. Ind. Ceram., 59(2), 179 – 183 (2018).

Y. Wang, S. Tan, and D. Jiang, “The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC,” Carbon, 42(8), 1833 – 1839 (2004).

J. C. Margiotta, D. Zhang, D. C. Nagle, and C. E. Feeser, “Formation of dense silicon carbide by liquid silicon infiltration of carbon with engineered structure,” J. Mater. Res., 23(5), 1237 – 1248 (2008).

P. Barick, D. C. Jana, and N. Thiyagarajan, “Effect of particle size on the mechanical properties of reaction bonded boron carbide ceramics,” Ceram. Int., 39(1), 763 – 770 (2013).

C. Zhang, H. Ru, H. Zong, et al., “Coarsening of boron carbide grains during the infiltration of porous boron carbide preforms by molten silicon,” Ceram. Int., 42(16), 18681 – 18691 (2016).

L. Sun, D. Ma, L. Wang, et al., “Determining indentation fracture toughness of ceramics by finite element method using virtual crack closure technique,” Eng. Fract. Mech., 197(6), 151 – 159 (2018).

F. Dai, R. Chen, and K. Xia, “A semi-circular bend technique for determining dynamic fracture toughness,” Exp. Mech., 50(6), 783 – 791 (2010).

A. Moradkhani, H. Baharvandi, M. Tajdari, H. Latifi, and J. Martikainen, “Determination of fracture toughness using the area of micro-crack tracks left in brittle materials by Vickers indentation test,” J. Adv. Ceram., 2(1), 87 – 102 (2013).

S. N. Perevislov, A. S. Lysenkov, and S. V. Vikhman, “Effect of Si additions on the microstructure and mechanical properties of hot-pressed B4C,” Inorg. Mater., 53(4), 376 – 380 (2017).

X. Li, D. Jiang, J. Zhang, et al., “Reaction-bonded B4C with high hardness,” Int. J. Appl. Ceram. Tech., 13(3), 584 – 592 (2016).

S. Hayun, A. Weizmann, M. P. Dariel, and N. Frage, “The effect of particle size distribution on the microstructure and the mechanical properties of boron carbide-based reaction-bonded composites,” Int. J. Appl. Ceram. Tech., 6(4), 492 – 500 (2009).

D. D. Nesmelov and S. N. Perevislov, “Reaction sintered materials based on boron carbide and silicon carbide,” Glass Ceram., 71(9/10), 313 – 319 (2015).

N. Frage, L. Levin, and M. P. Dariel, “The effect of the sintering atmosphere on the densification of B4C ceramics,” J. Solid State Chem., 177(2), 410 – 414 (2004).

S. Hayun, A. Weizmann, H. Dilman, et al., “Rim region growth and its composition in reaction bonded boron carbide composites with core-rim structure,” J. Phys.: Conference Series, IOP Publishing, 176(1), 1 – 7 (2009).

D. Mallick, T. K. Kayal, J. Ghosh, et al., “Development of multi-phase B–Si–C ceramic composite by reaction sintering,” Ceram. Int., 35(4), 1667 – 1669 (2009).

S. N. Perevislov and D. D. Nesmelov, “Properties of SiC and Si3N4 based composite ceramic with nanosize component,” Glass Ceram., 73(7/8), 249 – 252 (2016).

S. N. Perevislov, A. S. Lysenkov, D. D. Titov, M. V. Tomkovich, “Hot-pressed ceramic SiC–YAG materials,” Inorg. Mater., 53(2), 206 – 211 (2017).

S. Xu, G. Qiao, D. Li, et al., “Reaction forming of silicon carbide ceramic using phenolic resin derived porous carbon preform,” J. Eur. Ceram. Soc., 29(11), 2395 – 2402 (2009).

J. H. Chae, J. S. Park, J. P. Ahn, and K. H. Kim, “Mechanical properties of B4C ceramics fabricated by a hot-press sintering,” J. Korean Ceram. Soc., 46(1), 81 – 85 (2009).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 3, pp. 49 – 54, March 2019.

Rights and permissions

About this article

Cite this article

Perevislov, S.N. Evaluation of the Crack Resistance of Reactive Sintered Composite Boron Carbide-Based Materials. Refract Ind Ceram 60, 168–173 (2019). https://doi.org/10.1007/s11148-019-00330-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-019-00330-0