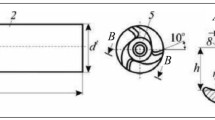

We develop a procedure aimed at the analysis of the main regularities of external burnishing of cylindrical billets of 40Kh steel with the use of a tool made of Al2O3–TiC ceramics. On the basis of results of experimental investigations, we construct a system of operation of a ceramic burnisher that takes into account the stress-strain state of the ceramics in the zone of contact with the billet.

Similar content being viewed by others

Change history

25 May 2019

The Acknowledgement on page 105 should read

References

A. G. Suslov, Quality of the Surface Layer of Machine Components [in Russian], Mashinostroenie, Moscow (2000).

L. G. Odintsov, Finish Machining of the Components by Diamond Burnishing and Vibroburnishing [in Russian], Mashinostroenie, Moscow (1981).

N. A. Lalazarova, L. I. Putyatina, L. A. Timofeeva, et al., “Control of the surface quality in the process of diamond burnishing of components made of high-strength cast iron,” Vest. KhNADU, Issue 54, 114 – 117 (2011).

G. P. Bashkov, Burnishing of Renovated Components [in Russian], Mashinostroenie, Moscow (1979).

Ya. I. Barats, Finish Plastic Metal Working (Thermal Physics and Quality) [in Russian], Saratov University, Saratov (1982).

V. M. Torbilo, Diamond Burnishing [in Russian], Mashinostroenie, Moscow (1972).

V. V. Kuzin, “Effective use of high-density ceramic for manufacture of cutting and working tools,” Refract. Industr. Ceram., 51(6), 421 – 426 (2010).

V. N. Gadalov, D. N. Romanenko, V. V. Samoilov, et al., “Procedure for the evaluation of the surface roughness of electric-spark coatings after burnishing by mineral ceramics,” Izv. Vyssh. Uchebn. Zaved., Poroshk. Metallurg. Funkts. Pokryt., No. 4, 44 – 46 (2010).

S. N. Grigor’ev and V. V. Kuzin, “Prospects for tools with ceramic cutting plates in modern metal working,” Glass Ceram., 68(7 – 8), 253 – 257 (2011).

V. V. Kuzin, S. Yu. Fedorov, and M. Yu. Fedorov, “Contact processes in cutting by ceramic tools,” Vest. MGTU “Stankin,” No. 4, 85 – 94 (2010).

A. S. Vereshchaka, V. M. Provotorov, V. V. Kuzin, et al., “Investigation of the thermal state of cutting tools with the help of temperature-indicating substances,” Vestn. Mashinostr., No. 1, 45 – 49 (1986).

M. A. Volosova and V. V. Kuzin, “Regular features of wear of cutting plates from oxide and nitride ceramics,” Met. Sci. Heat Treat., 54(1 – 2), 41 – 46 (2012).

V. V. Kuzin, “Increasing the operational stability of nitride-ceramic cutters by optimizing their grinding conditions,” Russ. Eng. Res., 23(12), 32 – 36 (2003).

V. V. Kuzin, “Thermal state of ceramic cutting tools in high-speed cutting,” Russ. Eng. Res., 24(9), 32 – 40 (2004).

V. Kuzin, S. N. Grigoriev, and M. Yu. Fedorov, “Role of the thermal factor in the wear mechanism of ceramic tools. Part 2: Microlevel,” J. Frict. Wear, 36(1), 40 – 44 (2015).

V. V. Kuzin, M. R. Portnoi, and S. Yu. Fedorov, “Stress inhomogeneity in oxide-carbide ceramic surface with developed relief under action of heat flow,” Refract. Industr. Ceram., 56(5), 557 – 560 (2016).

V. V. Kuzin, “Microstructural model of ceramic cutting plate,” Russ. Eng. Res., 31(5), 479 – 483 (2011).

V. V. Kuzin, “Methodological approach to the increase in the serviceability of ceramic tools,” Vestn. Mashinostr., No. 9, 87 – 88 (2006).

The work was performed with financial support of the Ministry of Education and Science of the Russian Federation within the framework of execution of the state assignment in the field of scientific activity (Assignment No. 2014/105, Project No. 1908).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, February, pp. 63 – 68, 2018

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Grigor’ev, S.N. & Volosova, M.A. System of Operation of Ceramic Tools in the External Burnishing of Cylindrical Billets. Refract Ind Ceram 59, 100–105 (2018). https://doi.org/10.1007/s11148-018-0190-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0190-8