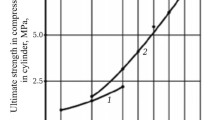

It is established that there are three stages in molding mixture pelletization: nucleus formation, granule growth, and mass transfer between them. Addition of a surfactant improves granulation capacity and reduces molding moisture content, and increases raw granule strength. The fineness of the starting material has a significant effect on capillary reaction forces that are fundamental during molding mixture pelletization.

Similar content being viewed by others

Author information

Authors and Affiliations

Corresponding author

Additional information

1Parts 1 and 2 published in Novye Ogneupory No. 7 (2017), part 3 in No. 9 (2017), and part 4 in No. 11 (2017).

Translated from Novye Ogneupory, No. 1, pp. 55 – 59, January, 2018.

Rights and permissions

About this article

Cite this article

Sokov, V.N. Highly Porous Granulated Corundum Filler of Alumina-Foam Polystyrene Mixture. Part 5. Effect of Molding Mixture Fineness and Moisture Content on Filler Granulation Capacity and Physicotechnical Properties1. Refract Ind Ceram 59, 54–58 (2018). https://doi.org/10.1007/s11148-018-0182-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0182-8