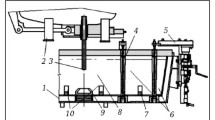

We consider the refractory equipment of section continuous billet-casting machines (CBCM) of the following system: tundish ladle (TL)–submerged nozzle (SN)–crystallizer, and analyze the processes of control over the metal flows in this system. We indicate the specific features of the structure of elements of section CBCM responsible for the rational transportation of the poured metal in the TL–SN–crystallizer system and the efficient formation of steel flows in the crystallizer and creating conditions for the enhancement of the quality of metal.

Similar content being viewed by others

References

V. V. Tochilkin, “Modernization of the tundish ladle of CBCM for the improvement of the quality of cast steel,” Remont Vosstan. Moderniz., No. 2, 5 – 7 (2007).

K. N. Vdovin, V. V. Tochilkin, and O. A. Marochkin, “Application of plastic refractories of improved design for the protection of metal stream in the process of casting on section CBCM,” Novye Ogneupory, No. 1, 3 – 5 (2014).

K. N. Vdovin, V. V. Tochilkin, O. A. Marochkin, et al., “New plastic refractory linings for protecting a metal stream during pouring into a CBCM,” Refract. Ind. Ceram., 55(4), 318 – 320 (2014).

K. N. Vdovin, Vas. V. Tochilkin, and Vik. V. Tochilkin, “Technologies for controlling flows of steel and the development of refractory structures for the tundish of a four-strand continuous caster,” Refract. Ind. Ceram., 57(1), 6 – 8 (2016).

K. N. Vdovin, S. N. Ushakov, O. A. Marochkin, and V. V. Tochilkin, “Development of the system of argon feed for the tundish ladle of the section CBCM,” Tekhnol. Met., No. 6, 38 – 40 (2013).

K. N. Vdovin, Vas. V. Tochilkin, and Vik. V. Tochilkin, “Analysis of operation of a steel-pouring ladle-tundish system for a sectional CBCM and improved refractory structures for the tundish receiving chamber,” Refract. Ind. Ceram., 57(3), 221 – 223 (2016).

K. N. Vdovin, V. V. Tochilkin, and I. M. Yachikov, “Designing refractories for the tundish of a continuous caster,” Refract. Ind. Ceram., 56(6), 569 – 573 (2016).

V. V. Tochilkin, “A procedure for the numerical analysis of a metal reservoir for the tundish ladle of CBCM,” Remont Vosstan. Modern., No. 6, 44 – 47 (2008).

I. M. Yachikov, K. N. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Simulation of the growth of metal skin in a sectional crystallizer in the presence of displacement of the stream relative to its axis,” Izv. Vyssh. Uchebn. Zaved., Chern. Met., 60(1), 24 – 29 (2017). DOI: https://doi.org/10.17073/0368-0797-2017-1-24-29.

K. N. Vdovin, V. V. Tochilkin, R. I. Abdrakhmanov, et al., “Comparative analysis of the application of different systems for rapid replacements of metering nozzles in the course of steel casting on section CBCMs,” Novye Ogneupory, No. 10, 62 – 64 (2014).

K. N. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Improvement of steel pouring in sectional CBCM,” Metallurgist, 58(4), 306 – 309 (2014).

K. N. Vdovin, V. V. Tochilkin, and I. M. Yachikov, Continuous Steel Casting. Hydromechanics of Continuous Billet-Casting Machines [in Russian], Izd. Magnitogorsk Gos. Tekh. Univ., Magnitogorsk (2014).

J. Szekely, “Computer construction (CAD-CAM-method) of the tundish,” in: J. Szekely and N. El Kadakh, Injection Metallurgy’86 [Russian translation], Metallurgiya, Moscow (1990), pp. 134 – 146.

K. N. Vdovin, V. F. Mysik, and V. V. Tochilkin, Design of Steelmaking Shops: A Textbook [in Russian], Izd. Magnitogorsk Gos. Tekh. Univ., Magnitogorsk (2016).

A. V. Antsupov, V. P. Antsupov, M. G. Slobodianskii, and V. A. Rusanov, “Energy-mechanical concept of the durability prediction of friction units on the wear resistance criterion of elements,” J. Frict. Wear, 37(5), 494 – 499 (2016). DOI: https://doi.org/10.3103/S1068366616050032.

K. N. Vdovin, O. A. Marochkin, and V. V. Tochilkin, “Creating a stream simulator to improve the wear resistance of refractories during the casting of steel on continuous section casters,” Refract. Ind. Ceram., 54(6), 435 – 437 (2013).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, February, pp. 3 – 6, 2018.

Rights and permissions

About this article

Cite this article

Tochilkin, V.V., Filatova, O.A., Umnov, V.I. et al. Analysis of the Process of Metal Casting and the Structure of Refractory Equipment of the “Tundish Ladle – Submerged Nozzle – Crystallizer” System of a Section CBCM. Refract Ind Ceram 59, 6–9 (2018). https://doi.org/10.1007/s11148-018-0172-x

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0172-x