The significance of the question of corrosion and erosion resistance for refractory materials in direct heating electric furnaces for vitrification of highly active waste (HAW) is substantiated. Algorithms are provided for evaluating their resistance to action of phosphate melts under electric furnace operating conditions. Comparative corrosion tests are performed for refractory materials surpassing Bk-33 objects with respect to quality in melts of aluminophosphate glass with simulation of HAW. Tests results are valuable for selecting lining material in planning ÉP-500 type vitrification electric furnaces with a prolonged service life, and also the next generation of moveable and small-scale melting units.

Similar content being viewed by others

References

V. D. Tokarev, S. M. Ignat’ev, and O. M. Popov, “Analysis of refractory material service in glass-melting furnace baths,” Steklo Keram., No. 5, 19 – 22 (2006).

Ya. Stanek, Electric Melting of Glass [Russian translation], Legkaya Industriya, Moscow (1979).

M. B. Remizov, P. V. Kozlov, M. V. Logunov, et al., “Conceptual and technical solutions for creating vitrification units of flowing and accumulated liquid HAC in PO Mayak,” Vopr. Radiats. Bezopasnosti, No. 3, 17 – 25 (2014).

Prospectus of the firm Zhengzhou Yuandong Refractory Co., Ltd., Wulibao Industrial Zone, Dawei, Xinmi, Henan, China.

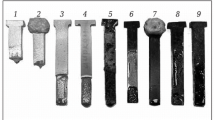

M. B. Remizov, A. A. Kazadaev, P. V. Kozlov, et al., “Corrosion testing of melted and cast refractory materials in melts of aluminophosphate glasses,” Ogneupor. Tekhn. Keram., No. 6, 3 – 8 (2015).

M. B. Remizov, A. A. Kazadaev, P. V. Kozlov, et al., “Study of the corrosion resistance of baddeleyite-corundum and chrome-alumina-zirconia refractory materials of domestic and imported production in melts of aluminoborophosphate glasses,” Ogneupor. Tekhn. Keram., No. 4/5, 3 – 7 (2015).

S. A. Popov, Corrosion and Service of Refractory Materials in Glass-Melting Furnace Baths During High-Temperature Glass Melting: Review [in Russian], VNIIÉSM, Moscow (1974).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 1, pp. 3 – 7, January, 2018.

Rights and permissions

About this article

Cite this article

Remizov, M.B., Kozlov, P.V., Kazadaev, A.A. et al. Corrosion Testing of Baddeleyite-Corundum and Chromium Oxide Materials in Aluminum Phosphate Glass Melts. Refract Ind Ceram 59, 1–5 (2018). https://doi.org/10.1007/s11148-018-0171-y

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0171-y