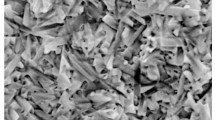

Features of Si3N4-ceramic specimen edge morphology formation with diamond surface grinding are studied, and forms of chipping and geometric parameters are determined. On the basis of correlation revealed for grinding depth, horizontal and longitudinal feed with geometric parameters of chipping, a requirement is determined for planning a production process for manufacturing components and tools of Si3N4-ceramic taking account of edge defectiveness.

Similar content being viewed by others

References

S. N. Grigor’ev, “Solution of problems for engineering production re-equipment,” Vestn. MGTU Stankin, No. 3, 5 – 9 (2008).

B. Zhang, T. Uematsu, and A. Nakajima, “High efficiency and precision grinding of Si3N4 ceramic balls aided by magnetic fluid support using diamond wheels,” JSME Int. J. Series C, 41(3), 499 – 505 (1998).

V. V. Kuzin, “Technology for machining high refractory ceramic parts based on silicon nitride,” Refract. Indust. Ceram., 47(4), 204 – 208 (2006).

V. V. Kuzin, “Increase in the operational stability of nitride-ceramic cutters by optimizing their grinding Conditions,” Russian Engineering Research, 23(12), 32 – 36 (2003).

W. Pfeiffer and T. Hollstein, “Influence of grinding parameters on strength-dominating near-surface characteristics of silicon nitride ceramics,” J. Eur. Ceram. Soc., 17, 487 – 494 (1997).

V. V. Kuzin, “Technological aspects of diamond grinding of the nitride ceramics,” Russian Engineering Research, 24(1), 23 – 28 (2004).

Z.-H. Xie, R. J. Moon, M. Hoffman, et al., “Role of microstructure in the grinding and polishing of a-sialon ceramics,” J. Eur. Ceram. Soc., 23, 2351 – 2360 (2003).

V. Kuzin, “A model of forming the surface layer of ceramic parts based on silicon nitride in the grinding Process,” Key Engineering Materials. Precision Machining, 496, 127 – 131 (2012).

Y. Zheng, J. M. Vieira, F. J. Oliveira, et al., “Relationship between flexural strength and surface roughness for hot-pressed Si3N4 self-reinforced ceramics,” J. Eur. Ceram. Soc., 20, 1345 – 1353 (2000).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Correlation of diamond grinding regimes with Si3N4-ceramic surface quality,” Refract. Indust. Ceram., 58(1), 78 – 81 (2017).

M. Martin-Gil, M. E. Rabanal, A. Varez, et al., “Mechanical grinding of Si3N4 to be used as an electrode in lithium batteries,” Materials Letters, 57, 3063 – 3069 (2003).

V. Kuzin, S. Grigoriev, S. Fedorov, and M. Fedorov, “Surface defects formation in grinding of silicon nitride ceramics,” Appl. Mechan. Mater., 752/753, 402 – 406 (2015).

M. Jiang and R. Komanduri, “On the finishing of Si3N4 balls for bearing applications,” Wear, 215, 267 – 278 (1998).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Features of surface morphology formation for Al2O3–TiC-ceramic specimens during diamond grinding,” Novye Ogneupory, No. 5, 63 – 67 (2017).

V. V. Kuzin, S. Yu. Fedorov, and S. N. Grigor’ev, “Level of edge defectiveness for Y-TZP-ceramic after diamond grinding, “Novye Ogneupory, No. 7, 53 – 65 (2017).

The present work is supported by the RF Ministry of Education and Science within the scope of an MGTU STANKIN state assignment in the sphere of scientific activity (assignment 9.1372.2017/4.6).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 9, pp. 65 – 68, September, 2017.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Fedorov, S.Y. & Grigor’ev, S.N. Production Process Planning for Preparing Si3N4-Ceramic Objects Taking Account of Edge Defectiveness. Refract Ind Ceram 58, 562–565 (2018). https://doi.org/10.1007/s11148-018-0145-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-018-0145-0