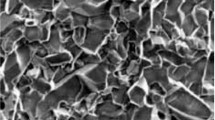

Results are provided for analysis of research results obtained by different scientific schools for abrasive-diamond and boron nitride machining of metal and ceramic materials. Acombined grinding efficiency coefficient RcEfG is suggested for measuring the ceramic grinding efficiency. Mathematical models are obtained of surface roughness for index Ra with surface and circular grinding of quartz ceramic based on SiO2.

Similar content being viewed by others

References

V. A. Rogov. M. I. Shkarupa, and D. K. Grishin, “Comparative analysis of machining ultrahard ceramic materials,” Vestn. RUDN. Inzh. Issled., No. 2, 15 – 21 (2008).

A. V. Pilinskii, “Innovative methods and ways in high-speed and ultra-rapid grinding,” Vektor Nauki TGU, No. 3, 136 – 144 (2015).

I. P. Nikiforov, Contemporary Trends in Abrasive Grinding and Abrasive Treatment: Monograph [in Russian], TNT, Staryi Oskop (2016).

O. V. Dushko and V. M. Shumyacher, Abrasive Grinding of Silicon Carbide Ceramic for Engineering: Monograph [in Russian], Volg-GASU, Volgograd (2009).

Yu. M. Zubarev and A. V. Priemyshev, Theory and Practice of Improving the Efficiency of Grinding Materials: Textbook [in Russian], Lan’, St Petersburg (2010).

N. V. Nikitkov and V. B. Rabinovich, High-Speed Diamond Machining of Engineering Ceramic Components [in Russian], Mashinostroenie, Leningrad (1984).

Z. N. Kremen’V. G. Yurev, and A. F. Baboshkin, Grinding Technology in Engineering [in Russian], Politekhnika, St. Petersburg (2007).

V. A. Rogov, M. I. Shkarupa, and V. V. Kopylov, “Preparation of a mathematical model of surface quality for a component of the shell of rotation type made of quartz structural ceramic,” Vestn. RUDI. Inzh. Issled., No. 3, 68 – 73 (2011).

M. I. Shkarupa, “Increase in machining efficiency and physicotechnical treatment of components of the shell of rotation type made of structural ceramic,” Diss. Cand. Techn. Sci., Moscow (2011).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 5, pp. 56 – 62, May, 2017.

Rights and permissions

About this article

Cite this article

Shkarupa, M.I., Dudakov, V.B., Lashnev, M.M. et al. Main Aspects of Improving Abrasive Treatment Efficiency for Structural and Functional Ceramic Objects. Refract Ind Ceram 58, 312–318 (2017). https://doi.org/10.1007/s11148-017-0102-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0102-3