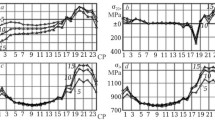

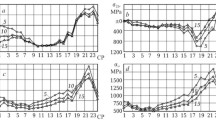

The effect of titanium carbide coating thickness on transformation of the stressed state of a Si3N4–TiC–Y2O3-ceramic surface layer under action of heat flow is studied. It is established as a result of numerical experiments that an increase in TiC coating thickness from 5 to 15 μm, applied to nitride ceramic, leads to a reduction in ceramic temperature, and increase in σ11, σ22, σ12, and σ i , and indices of their structural inhomogeneity in a ceramic surface layer.

Similar content being viewed by others

References

W. O. Soboyejo, J. D. Obayemi, E. Annan, et al., “Review of high temperature ceramics for aerospace applications,” Advanced Mater. Res., 1132, 385 – 407 (2016).

V. V. Kuzin, S. I. Dos’ko, V. F. Popov, et al., “Tooling for high-speed cutting,” Russ. Eng. Res., 25(9), 20 – 25 (2005).

U. De, “Ferroelectric materials for high temperature piezoelectric applications,” Solid State Phenomena, 232, 235 – 278 (2015).

A. MohdNor, M. R. Abbas, S. Rajoo, et al., “Review on ceramic application in automotive turbocharged engine,” Appl. Mechan. Mater., 660, 219 – 228 (2014).

V. V. Kuzin, “Effectiveness of the nitride ceramic cutting tools in machining the gray irons,” Russ. Eng. Res., 24(5), 21 – 27 (2004).

V. V. Kuzin, “Thermal state of ceramic cutting tools in highspeed cutting,” Russ. Eng. Res., 24(9), 32 – 40 (2004).

V. V. Kuzin, S. N. Grigor’ev, and S. Yu. Fedorov, “Wear of nitride ceramic inserts in machining gray cast iron castings,” Russ. Eng. Res., 33(6), 343 – 347 (2013).

V. V. Kuzin, S. N. Grigor’ev, and S. Yu. Fedorov, “Wear of tools from nitride ceramics when machining nickel-based alloys,” J. Friction and Wear, 34(3), 199 – 203 (2013).

V. V. Kuzin, S. N. Grigoriev, and M. A. Volosova, “The role of the thermal factor in the wear mechanism of ceramic tools. Part 1. Macrolevel,” J. Friction and Wear, 35(6), 505 – 510 (2014).

V. V. Kuzin, S. N. Grigoriev, and M. Yu. Fedorov, “Role of the thermal factor in the wear mechanism of ceramic tools. Part 2. Microlevel,” J. Friction and Wear, 36(1), 40 – 44 (2015).

D. W. Kim, Y. J. Park, J. G. Lee, and J. S. Chun, “TiC and TiN coatings formed on Si3N4–TiC composite ceramics by chemical vapour deposition,” Thin Solid Films, 165(1), 149 – 161 (1988).

F. A. Almeida, M. Belmonte, A. J. S. Fernandes, et al., “MPCVD diamond coating of Si3N4–TiN electroconductive composite substrates,” Diamond and Related Materials, 16(4 – 7), 978 – 982 (2007).

S. N. Grigor’ev and M. A. Volosova, “Engineering of a metal cutting tool surface by combined vacuum-plasma treatment. Part 1,” Remont, Vosstan., Modernizatsiya, No. 7, 2 – 6 (2004).

V. Kuzin and S. Grigoriev, “Tool life and wear mechanism of coated Si3N4 ceramic tools in turning grey cast iron,” Key Engin. Mater., 581, 14 – 17 (2014).

S. Grigoriev, V. Kuzin, D. Burton, and D. Batako, “The stressstrained state of ceramic tools with coating,” Proc. 37th Internat. Conf. MATADOR, 2012.

V. Kuzin, S. Grigoriev, and M. Fedorov, “Applications of multi-level method of stress-strain state analysis in ceramic tools design,” Appl. Mechan. Mater., 827, 173 – 176 (2016).

V. Kuzin, S. Grigoriev, M. Volosova, et al., “Designing of details taking into account degradation of structural ceramics at exploitation,” Appl. Mechan. Mater., 752/753, 268 – 281 (2015).

S. N. Grigor’ev, V. V. Kuzin, and M. A. Volosova, “Stress-strain state of a coated nitride-ceramic tool,” Russ. Eng. Res., 32(7/8), 561 – 566 (2012).

S. N. Grigor’ev, V. V. Kuzin, D. Burton, et al., “Influence of ceramic properties on the stress-strain state of a plate in steady heat conduction,” Russ. Eng. Res., 32(4), 374 – 379 (2012).

V. V. Kuzin, S. N. Grigor’ev, and M. A. Volosova, “Effect of a TiC coating on the stress-strain state of a plate of a high-density nitride ceramic under nonsteady thermoelastic conditions,” Refract. Indus. Ceram., 54(5), 376 – 380 (2014).

M. A. Volosova, S. N. Grigor’ev, and V. V. Kuzin, “Effect of titanium nitride coating on stress structural inhomogeneity in oxide-carbide ceramic. Part 4. Action of heat flow,” Refract. Indus. Ceram., 56(1), 91096 (2015).

V. V. Kuzin and M. Yu. Fedorov, “Transformation of the stressed state of a surface layer of nitride ceramic with a change in thickness of a TiC-coating. Loading version, a concentrated force load operates,” Novye Ogneupory, No. 8, 59 – 65 (2016).

V. V. Kuzin and M. Yu. Fedorov, ““Transformation of the stressed state of a surface layer of nitride ceramic with a change in thickness of a TiC-coating. Loading version, a distributed force load operates,” Novye Ogneupory, No. 10, 58 – 63 (2016).

V. Kuzin and S. Grigoriev, “Method of investigation of the stress-strain state of surface layer of machine elements from a sintered nonuniform material,” Appl. Mechan. Mater., 486, 32 – 35 (2014).

Work was carried out with support of the Russian Ministry of Education and Science within the scope of fulfilling a state assignment in the sphere of scientific activity.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 2, pp. 54 – 60, February, 2017.

Rights and permissions

About this article

Cite this article

Kuzin, V.V., Fedorov, M.Y. & Volosova, M.A. Nitride Ceramic Surface Layer Stressed State Transformation with a Change in TiC-coating Thickness. Stress Version — Heat Flow. Refract Ind Ceram 58, 82–88 (2017). https://doi.org/10.1007/s11148-017-0059-2

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-017-0059-2