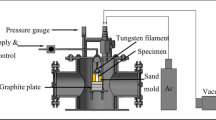

A fundamental possibility is demonstrated of using SHS-extrusion and SHS-compression methods, combining combustion and high-temperature deformation, for preparing compact materials and objects of silicide ceramics based on MoSi2. Formability of silicide ceramic by free SHS-compression is studied. The effect of holding time before high-temperature deformation, heating temperature, and metal binder content in an original charge workpiece, on the degree of synthesized material deformation is studied. Specimen macro- and microstructure, prepared by SHS-extrusion is provided, and the effect of high-temperature heating on specific electrical resistance is also studied.

Similar content being viewed by others

References

A. G. Merzhanov, Material Combustion Processes and Synthesis, V. T. Telepa and A. V. Khachoyan, editors) [in Russian], ISMAN, Chernogolovka (1998).

Z. I. Zaki, Y. M. Nasser, and Y. M. Ahmed, “Synthesis of dense mullite/MoSi2 composite for high temperature applications,” Int. J. Refractory Metals & Hard Materials, 45, 23 – 30 (2014).

A. A. Sharif, A. Misra, and T. E. Mitchell, “Strength of MoSi2-based crystals at ultrahigh temperature,” Scripta Materialia, 52, 399 – 402 (2005).

P. S. Kislyi, A. Kh. Badyan, V. S. Kindysheva, et al., High-Temperature Nonmetallic Heaters [in Russian], Naukova Dumka, Kiev (1981).

L. G. Tkachev and M. Ya. Pogrebisskii, “Computer design of electric furnace resistance heaters used in metallurgy,” Élektrometallurgiya, No. 9, 42 – 46 (2000).

Yue Chen, T. Hammerschmidt, D. G. Pettifor, et al., “Influence of vibrational entropy on structural stability of Nb–Si and Mo–Si systems at elevated temperatures,” Acta Materialia, 57, 2657 – 2664 (2009).

F. A. Rioult, S. D. Imhoff, R. Sakidja, et al., “Transient oxidation of Mo–Si–B alloys: Effect of the microstructure size scale,” Acta Materialia, 57, 4600 – 4613 (2009).

S. T. Mileiko, “High-temperature metal matrix composites,” J. Appl. Mechan. Techn. Phys., 55(1), 136 – 146.

I. Grammenos and P. Tsakiropoulos, “Study of the role of Hf, Mo and W additions in the microstructure of Nb–20Si silicide based alloys,” Intermetallics, 19, 1612 – 1621 (2011).

A. M. Stolin and P. M. Bazhin, “Manufacture of multipurpose composite and ceramic materials in the combustion regime and high-temperature deformation (SHS Extrusion),” Theoretical Foundations of Chem. Eng., 48(6), 751 – 763 (2014).

S. N. Galyshev, A. M. Stolin, and P. M. Bazhin, “Preparation of intermetallic materials based on nickel aluminide by free SHS-compression,” Inzh. Fiz., No. 9, 25 – 28 (2009).

A. M. Stolin and P. M. Bazhin, “SHS extrusion: an overview,” Int. J. Self-Propagating High-Temperature Synthesis, 23(2), 65 – 73 (2014).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 6, pp. 56 – 61, June 2015.

Proceedings of the International Conference of Refractory Workers and Metallurgists (19 – 20 March 2015, Moscow).

Rights and permissions

About this article

Cite this article

Stolin, A.M., Bazhin, P.M., Mikheev, M.V. et al. Silicide Ceramic Synthesis Based on Molybdenum Disilicide in a Combustion Regime Under High-Temperature Deformation Conditions. Refract Ind Ceram 56, 304–309 (2015). https://doi.org/10.1007/s11148-015-9835-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9835-z