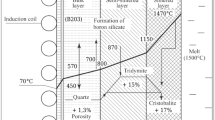

Results are presented from studies of the phase interactions that take place between the metal, lining, slag, and gas inside the lining of an industrial-frequency crucible-type induction furnace (CIF). The lining is composed of quartzite, boric acid, and electrocorundum. The phase composition of the lining is determined. The lining lasted 295 heats in the production of ferrous-metal alloys at temperatures up to 1570°C. The chemical and phase compositions of the slag-covered layer and the sintered layer of the lining are also determined.

Similar content being viewed by others

References

D. S. Belyakin, B. V. Ivanov, and V. V. Lapin, Petrography of Technical Cadmium [in Russian], Izd-vo AN SSSR, Moscow (1952).

B. P. Platonov, A. D. Akimenko, S. M. Bagutskaya, et al., Induction Furnaces for Refining Cast Iron [in Russian], Mashinostroenie, Moscow (1976).

V. A. Kukartsev, A. K. Abkaryan, and V. G. Babkin, “Study of the phase composition of a used quartzite lining from an industrial-frequency crucible-type induction furnace by using x-ray methods,” Novye Ogneupory, No. 11, 44 – 46 (20140.

B. P. Romanov, A. M. Sazonov, and A. V. Manankov, “Structural and phase relations in an enstatite-dioxide system at atmospheric pressure,” Geologiya i Geofizika, No. 10, 1326 – 1334 (1981).

I. S. Yakimov, “Cluster method for roentgenographic identification of multiphase materials,” Kontrol’. Diagnostika, No. 7, 12 – 17 (2010).

V. G. Babkin, B. V. Tsarevskii, and S. I. Popel’, “Spreading of oxide melts over the surface of molding materials,”Wettability and the Surface Properties of Melts and Solids [in Russian], Naukova Dumka, Kiev (1972), pp. 91 – 93.

A. S. Zavertkin, “Interaction of an acid lining with molten metal and slag in an induction-furnace heat of cast iron,” Problems on the Efficient Use of Natural and Technogenic Raw Materials in the Barents Region to make Industrial and Structural Materials,” Proc. Second International Scientific Technical Conference. KarNTs RAN, Petrozavodsk (2005), pp. 64 – 65.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 3. pp. 108 – 112, March, 2015.

Rights and permissions

About this article

Cite this article

Kukartsev, V.A., Sazonov, A.M., Babkin, V.G. et al. Effect of the Addition of Electrocorundum on Structural-Phase Transformations in the Quartz Lining of an Industrial-Frequency Crucible-Type Induction Furnace. Refract Ind Ceram 56, 151–154 (2015). https://doi.org/10.1007/s11148-015-9802-8

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9802-8