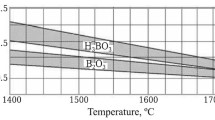

Results are presented from a study of the phase composition of spent quartzite lining from a crucible-type industrial frequency induction furnace. The study is performed by the methods of x-ray analysis. The lining that was examined contained quartzite, boric acid, and electrocorundum. Different regions of the lining were identified and their phase composition was determined along with the changes in the lattice parameters of the components of each region’s phases.

Similar content being viewed by others

References

B. P. Platonov, A. D. Akimenko,. M. Bagutskaya, et al., Induction Furnaces for Making Cast Iron [in Russian], Mashinostroenie, Moscow (1976).

V. A. Kukartsev and A. K. Abkaryan, “Study by x-ray methods of the effect of temperature on crystal lattice interplanar distances of Pervoural’sk quartzite used for induction furnace lining,” Novye Ogneupory, No. 10, 44 – 46 (2013).

A. G. Betekhtin, Course in Mineralogy: Text [in Russian], KDU, Moscow (2007).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Novye Ogneupory, No. 11, pp. 44 – 46, November, 2014.

Rights and permissions

About this article

Cite this article

Kukartsev, V.A., Abkaryan, A.K. & Babkin, V.G. Study of the Phase Composition of Spent Quartzite Lining from a Crucible-Type Industrial Frequency Induction Furnace by X-ray methods. Refract Ind Ceram 55, 529–531 (2015). https://doi.org/10.1007/s11148-015-9757-9

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-015-9757-9