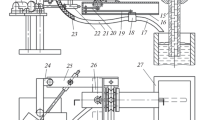

The quality and safety of the operation of continuous casting depend to a large extent on making the correct choices for the slag-forming mixture and the technology to use it. Automated systems developed to feed such mixtures make it possible to introduce a mixture into the mold in small and precisely measured amounts, which improves the surface quality of continuous-cast slabs, decreases the number of metal products rejected for defects of metallurgical origin, and reduces the consumption of slag-forming mixtures.

Similar content being viewed by others

Author information

Authors and Affiliations

Additional information

Translated from Novye Ogneupory, No. 4, pp. 39 – 42, April, 2013.

Rights and permissions

About this article

Cite this article

Gorostkin, S.V., Garten, V. Introduction of a system for automatically feeding a slag-forming mixture into the mold of a continuous caster. Refract Ind Ceram 54, 116–119 (2013). https://doi.org/10.1007/s11148-013-9560-4

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-013-9560-4