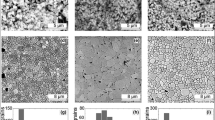

Results are provided for a study of the phase composition and fritting of magnesia silicate composite powder with a SiO2 content from 32 to 70%. The powder is prepared by a sol-gel method based on inorganic precursors. Optimum synthesis conditions and powder composition are indicated, providing a reduction in its fritting temperature.

Similar content being viewed by others

References

A. Kazakos, S. Komarneni, and R. Roy, “Preparation and densification of forsterite (Mg2SiO4) and nanocomposite sol-gel processing,” Materials Letters, No. 9/10, 405 – 409 (1990).

L. A. Kuznetsova, E. E. Grinburg, L. V. Shmelev, et al., “Preparation of single-phase crystalline substances of the MgO–SiO2 system by alkoxy technology,” Metalloorganicheskaya Khim., 6,, No. 6, 16 – 19 (1993).

M. T. Adrianov, “Sol-gel method in oxide material technology,” Steklo Keram., No. 10, 17 – 23 (2003).

G. A. Afonina, V. G. Leonov, and O. M. Popova, “Preparation of forsterite powder by sol-gel technology,” Steklo Keram., No. 8, 19 – 24 (2005).

Author information

Authors and Affiliations

Additional information

Translated from Novye Ogneupory, No. 1, pp. 38 – 40, January 2011.

Rights and permissions

About this article

Cite this article

Leonov, V.G., Afonina, G.A. & Popova, O.N. Synthesis and fritting of magnesia silicate composite powder. Refract Ind Ceram 52, 32–34 (2011). https://doi.org/10.1007/s11148-011-9359-0

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11148-011-9359-0