Abstract

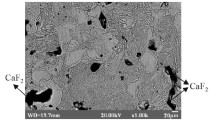

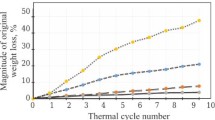

We describe the development of the technology of periclase-carbon composite refractories with a new complex binder, which combines the properties of phenolic resins and coal-tar pitch. Theoretical analysis and the results of application in steel teeming ladle lining show that a combination of these thermoreactive and thermoplastic components in the new binder provides a more compact (denser) structure of the coke framework (residue) possessing increased resistance to oxidation. Articles made of the new composite refractory have been successfully tested in the lining of steel teeming ladles. The wear characteristics of new lining materials in steel ladles has been studied.

Similar content being viewed by others

References

R. S. Takhautdinov, A. D. Nosov, and V. F. D’yachenko, “The Experiense in Using Periclase-Carbon Composite Lining in Converters at the Nizhneserginsk Metalware and Metallurgical Works,” Nov. Ogneupory, No. 3, 7–11 (2003).

F. S. Kaplan, L. M. Aksel’rod, and V. N. Koptelov, “Heat Conductivity of Carbon-Containing Refractories,” Nov. Ogneupory, No. 6, 46–49 (2003).

K. Maeda, O. Nakagawa, and E. Minamibuti, “Estimating Electric Conductivity and Corrosion Resistance of Magnesia-Carbonaceous Composite Refractories for Conductive Bottom of DC Electric-Arc Furnaces,” Taikabutsu, 47(8), 407–408 (1995).

V. I. Sizov, O. F. Shatilov, and V. N. Koptelov, “Prospects of Providing Domestic High-Quality Refractories for Electric Furnaces,” Stal’, No. 12, 29–30 (1999).

A. P. Nagornyi, I. D. Buga, A. B. Kovura, et al., “The Experiense in Using Periclase-Carbon Composite Refractories in Converter Lining,” Ogneupory Tekh. Keram., No. 12, 29 (1997).

“Neuerungen bei Feuerfestzustellungen für den LD-Stahlbereich,” Stahl Eisen, 112(5), 121–124 (1992).

W. Zhang, Carbon-Containing Composite Refractories, Science Press, Beijing (1990).

US Pat. No. 4454239, C04B 835/52, Jr. Cassens, Carbonaceous Refractory Composition for Pressing Brick Shapes.

K. K. Strelov, Theoretical Principles of Refractory Technology [in Russian], Metallurgiya, Moscow (1996).

S. Akai, K. Anan, and S. Takanaga, “Corrosion of MgO-C Bricks by Low-Basicity Slag,” J. Tech. Assoc. Refract. Jpn., 21(3), 217 (2001).

V. G. Ovsyannikov, O. B. Voronina, and V. F. D’yachenko, “Service of Periclase-Carbon Composite Refractories in the Lining of Steel Teeming Channel of a 340-ton Converter,” Ogneupory Tekh. Keram., No. 1, 7–9 (2002).

I. D. Kashcheev, Oxide-Carbon Composite Refractories [in Russian], Intermet Engineering, Moscow (2000).

S. G. Sennikov, V. N. Zhirikov, Yu. A. Puzyrev, et al., “Converter Lining Materials of Mayerton Refractories Company,” Ogneupory Tekh. Keram., No. 11, 47–51 (1999).

US Pat. No. 4184883, C08L 075/03, R. H. Hughes and R. Morena, Pitch Bonded Refractory.

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 8, pp. 14–20, August, 2007.

Rights and permissions

About this article

Cite this article

Yarushina, T.V., Akbashev, V.A., Plyukhin, V.A. et al. Periclase-carbon composite refractories with a new complex binder. Refract Ind Ceram 48, 170–175 (2007). https://doi.org/10.1007/s11148-007-0053-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-007-0053-1