Abstract

The engineering center at Borovichi Refractory Corporation has researched the optimization of composition for periclase-spinel components for lining the sintering zone in a rotating oven for firing cement clinker. The best composition and the best ratios between the additives have been established for the addition to the finely ground material, and the composition has been determined together with the best amount of temperature compensator, which is needed to improve the thermomechanical properties of the components and give preset working-life characteristics.

Similar content being viewed by others

References

V. I. Shubin, V. I. Zharkov, and G. Yu. Vasilik, The State of the Russian Cement Industry in 2004–2005 and Development Prospects [in Russian], Tsement i ego Primenenie, No. 6, 14–23 (2005).

V. I. Shubin, V. I. Zharkov, G. Yu. Vasilik, et al., “The Russian cement production and market in 2004,” Informtsement (Proceedings of the Seminar on Refractories and Refractory Linings for Rotating Cement Furnaces) [in Russian] (2005), pp. 12–27.

I. D. Kashcheev and E. E. Grishenkov (eds), Refractories for Industrial Plants and Furnaces. Volume 2. Refractory Service [in Russian], Intermet Engineering, Moscow (2002), pp. 465–520.

“Digest,” Tsement i ego Primenenie, No. 3, 46–48 (2001).

Y. Hong, J. Sun, and Z. Li, “A study on damage mechanism of restricted CaO to magnesia alumina spinel,” in: Stahl und Eisen Special, XXXIX Intern. Colloquium on Refractories (1996), pp. 181–184.

G. V. Kukolev, Silicon Chemistry and Silicate Physical Chemistry [in Russian], State Publisher of Literature on Building Materials, Moscow (1951), pp. 401–403.

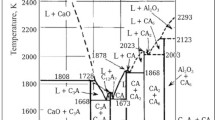

Phase Diagrams for Silicate Systems: Fourth Edition [in Russian], Nauka, Moscow (1974), pp. 38–430.

S. L. Akhnazarova and V. V. Kafarov, Methods of Optimizing Experiments in Chemical Engineering [in Russian], Vysshaya Shkola, Moscow (1995), pp. 159–188.

V. I. Shubin, V. Ya. Sakulin, V. P. Migal’, et al., “The interaction of periclase-spinel items with cement clinker,” Informtsement (Proceedings of the Seminar on Refractories and Refractory Linings for Rotating Cement Furnaces) [in Russian] (2005), pp. 41–50.

V. I. Shubin, Research, Development, and Introduction of Methods of Raising the Resistance and Performance of Linings for Rotating Cement Industry Furnaces. Author’s Abstract of Candidate’s Thesis [in Russian], Moscow (1997).

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 3, pp. 134–137, March, 2007.

Rights and permissions

About this article

Cite this article

Shubin, V.I., Sakulin, V.Y., Migal’, V.P. et al. Choosing functional additives for optimizing the properties of periclase-spinel components. Refract Ind Ceram 48, 69–72 (2007). https://doi.org/10.1007/s11148-007-0029-1

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-007-0029-1