Abstract

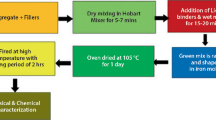

Refractory mixes of high alumina composition are developed for plastic molding. The mixes are distinguished from more traditional ones by a low clay content (by a factor of 3–5) due to introduction into the mix composition of highly concentrated ceramic binding suspension based on high alumina fireclay that promotes an improvement in the basic physicomechanical properties of articles made from these mixes.

Similar content being viewed by others

References

Yu. E. Pivinskii, Unmolded Refractories. General Questions of Technology [in Russian], Teploé nergetik, Moscow (2003).

I. S. Kainarskii (ed.), Refractories and Linings [in Russian], Metallurgiya, Moscow (1976).

Ya. Inamura (ed.), Refractories and Their Application [Russian translation, A. G. Yudin], Metallurgiya, Moscow (1984).

Monolithic Refractory Technology, Plibrico, Vienna (1994).

Yu. E. Pivinskii, “New refractory composites and binder systems, basic direction in developing, producing and using refractories in the 21st century. Part IV. Low-cement concretes and cementless unformed refractories,” Ogneupory i Tekhnicheskaya Keramika, No. 5, 2–10 (1998).

Yu. E. Pivinskii, Ceramic Binders and Ceramic Concretes [in Russian], Metallurgiya, Moscow (1990).

Yu. E. Pivinskii and A. V. Cherepatova, “Materials based on highly concentrated ceramic binder suspensions (HCBS). 3. Properties of mixed binders in the system HCBS quartz sand-refractory clay,” Ogneupory i Tekhnicheskaya Keramika, No. 8, 22–26 (1997).

Yu. E. Pivinskii and V. Yu. Belousova, “Materials based on highly concentrated ceramic binder suspensions (HCBS). Corundum and corundum-mullite ceramic concretes based on plastified HCBS bauxite,” Ogneupory i Tekhnicheskaya Keramika, No. 9, 13–18 (1999).

Yu. E. Pivinskii, “Rheology and technology of ceramics and refractories. 6. Dilation systems and factors determining their properties,” Ogneupory i Tekhnicheskaya Keramika, No. 4, 2–14 (1997).

Yu. E. Pivinskii, “Rheology and technology of ceramics and refractories. 8. Dispersed systems with a complex flow character,” Ogneupory i Tekhnicheskaya Keramika, No. 12, 2–8 (1998).

V. L. Baklevich and Yu. M. Mosin, Rheological Properties of Ceramic Mixes [in Russian], D. I. Mendeleev MKhTI, Moscow (1983).

Yu. E. Pivinskii, V. A. Doroganov, and E. A. Doroganov, “Refractory plastic mixes based on highly concentrated ceramic binder suspensions (HCBS). I. Structural and mechanical properties of suspensions (pastes) of refractory clays,” Ogneupory i Tekhnicheskaya Keramika, No. 4, 14–19 (2000).

V. A. Doroganov, Yu. E. Pivinskii, and E. A. Doroganov, “Refractory plastic mixes based on highly concentrated ceramic binder suspensions (HCBS). II. Structural and mechanical properties of plastified HCBS in the system SiO2-clay,” Ogneupory i Tekhnicheskaya Keramika, No. 3, 17–21 (2001).

V. A. Doroganov, Yu. E. Pivinskii, and E. A. Doroganov, “Refractory plastic mixes based on highly concentrated ceramic binder suspensions (HCBS). III. Structural and mechanical properties of plastified mixes based on HCBS bauxite and some characteristics of materials based on it,” Ogneupory i Tekhnicheskaya Keramika, No. 4, 18–23 (2001).

V. A. Doroganov, Yu. E. Pivinskii, and A. V. Cherevatova, “Thinning and plastification of HCBS based on high silica fireclay,” Novye Ogneupory, No. 2, 25–29 (2004).

Yu. E. Pivinskii, Theoretical Aspects of Ceramic and Refractory Technology: Selected Works [in Russian], Stroizdat, St. Petersburg (2003).

Yu. E. Pivinskii, and V. A. Doroganov, “Structural and mechanical properties of plastified mixes based on HCBS of high alumina fireclay,” Novye Ogneupory, No. 12, 62–68 (2004).

S. P. Nichiporenko, Physicochemical Mechanics of Dispersed Structures in Structural Ceramic Technology [in Russian], Naukova Dumka, Kiev.

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 3, pp. 120–125, March, 2007.

Rights and permissions

About this article

Cite this article

Doroganov, V.A., Evtushenko, E.I. & Pivinskii, Y.E. Plastic molding refractory mixes based on highly concentrated ceramic binding suspensions of high alumina fireclay. Refract Ind Ceram 48, 63–68 (2007). https://doi.org/10.1007/s11148-007-0028-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-007-0028-2