Abstract

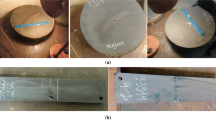

The defects of the existing methods for producing continuous lining for steel-casting ladles using sand-slinging units are demonstrated and a new solution of the problem is proposed. The proposed device is based on slinging briquettes using compressed air at a speed of 40–80 m/sec and frequency of 3–5 sec−1. The preliminary density of briquettes is 1.56–1.70 g/cm3; they are prepared on the same rotary briquette-slinging unit. The new unit has an original air-distributing control valve. Data are given on the application of a technogenic powder material in experimental studies.

Similar content being viewed by others

References

S. V. Kolpakov, “Energy saving in metallurgy,” Stal’, No. 3, 71 (2004).

Yu. E. Pivinskii, Non-Molded Refractories: Reference Book, Vol. 1. Book 1 [in Russian], Teploenergetik, Moscow (2003).

I. V. Matveensko, A. Z. Isagulov, and A. A. Daiker, Dynamic and Pulse Process and Machinery for Compacting Foundry Molds [in Russian], Gylym, Almaty (1998).

USSR Inventor’s Certificate No. 519283, S. V. Kolpakov, O. L. Bondarenko, E. D. Gugnin, et al., “The Orbita machine for lining metallurgical ladles,” Izobr., Otkr., No. 24 (1976).

N. I. Biryukov, N.M. Bashilov, and G. A. Konstantinov, “RF Patent No. 2214315, A sand-slinging unit,” Byull. Izobr., No. 29 (2003).

N. M. Bashilov, E. G. Chernyshevich, and A. A. Rodionov, “A briquetting rotor-pulse slinger for ramming continuous lining in metallurgical ladles and molds,” Liteishchik Rossii, No. 9, 37–39 (2004).

I. V. Matveenko, “Pulse and pulse-extrusion compaction of molds and rods,” Liteinoe Proizvod., No. 9, 16 (2001).

A. T. Elishevich, Briquetting Natural Minerals, A Manual [in Russian], Nedra, Moscow (1989).

S. V. Kolpakov and O. L. Bondarenko, “Service experience of the Orbita machine and steel-casting ladles of capacity 130–200 tons with continuous lining made of refractory ramming mixtures,” Stal’, No. 6, 13 (1976).

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 8, pp. 33–36, August, 2006.

Rights and permissions

About this article

Cite this article

Matveenko, I.V. A new method for dynamic compaction of bulk mixtures in ramming continuous ladle lining. Refract Ind Ceram 47, 237–240 (2006). https://doi.org/10.1007/s11148-006-0097-7

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-006-0097-7