Abstract

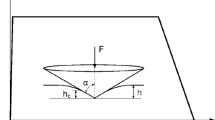

The use of vibratory techniques in the shaping of complex-shaped components, specifically, high-voltage insulators, by quasi-isostatic pressing are discussed. The advantage of quasi-isostatic pressing over hydrostatic pressing is emphasized.

Similar content being viewed by others

References

M. I. Timokhova, Factors Involved in the Hydrostatic Pressing of Electroceramic Components, Author’s Abstract of Candidate’s Thesis [in Russian], Moscow (1964).

R. Ya. Popil’skii and Yu. E. Pivinskii, The Pressing of Powdered Ceramic Mixtures [in Russian], Metallurgiya, Moscow (1983).

M. I. Timokhova, “Quasi-isostatic pressing of components from powder materials,” Novye Ogneupory, No. 11, 31–34 (2003).

M. I. Timokhova, “Quasi-isostatic pressing — a promising technology in the production of refractory components,” Novye Ogneupory, No. 6, 19–23 (2004).

M. I. Timokhova, “Volumetric quasi-isostatic pressing of powder materials,” Novye Ogneupory, No. 12, 43–44 (2004).

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 6, pp. 13–16, June, 2006.

Rights and permissions

About this article

Cite this article

Timokhova, M.I. Vibratory techniques in isostatic pressing technology. Refract Ind Ceram 47, 152–154 (2006). https://doi.org/10.1007/s11148-006-0076-z

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-006-0076-z