Abstract

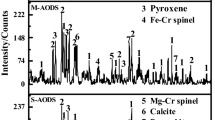

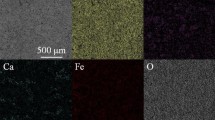

Specimens of post-service ShA-5-grade chamotte refractory are analyzed for total elemental aluminum and silicon. Products of the electrolysis of cryolitic melt Na (gas), AlF, Al2O, and, possibly, Na2F are shown to diffuse through pores of the carbon refractory bottom lining blocks of an aluminum electrolysis cell. The lower compounds and Na(gas) as they reach the refractory layer enter into a reaction with the refractory material. The Gibbs free energy of hypothetic reactions in the Al - Si - O - F - Na system involving a gas phase has been calculated. It is inferred that the performance characteristics of the ShA-5 refractory fail to meet standard operational requirements.

Similar content being viewed by others

REFERENCES

V. V. Sharapova, I. I. Lishchuk, D. Yu. Boguslavskii, and V. V. Chesnyak, “Part 1. Mineral composition and phase transformations in the refractory lining of the bottom of aluminum electrolysis cells,” Novye Ogneupory, No. 3, 13–17 (2005).

D. V. Pruttskov, I. M. Bastryga, T. F. Raichenko, et al., “Phase transformations in the chamotte brick of the base plate of an aluminum electrolysis cell,” Tsvetn. Met., No. 11, 41–43 (1986).

D. V. Pruttskov, A. B. Bukher, V. P. Pirozhkova, Yu. I. Rys'eva, V. E. Pruttskov, A. P. Khvalin, and S. N. Dotsenko, “A mechanism of failure of the lining of an aluminum electrolysis cell,” Zh. Prikl. Khim., No. 1, 61–66 (1986).

D. V. Pruttskov, P. I. Titaev, A. A. Andriiko, and V. P. Pirozhkova, “The cryolite-nepheline state diagram and thermodynamic activity of its components,” Ukr. Khim. Zh., 56(5), 470–475 (1990).

G. N. Kozhevnikov and A. G. Vodop'yanov, The Lower Oxides of Silicon and Aluminum for Electrometallurgy [in Russian], Nauka, Moscow (1977).

A. I. Belyaev, “The use of monovalent aluminum in the electrolytic preparation of aluminum,” Tsvetn. Metal., No. 6, 40–44 (1953).

M. B. Dell, “Aluminum electrolysis,” J. Met., 23(6), 18–20 (1971).

K. Grjjtheim, C. Krohn, M. Malinosry, et al., “Aluminium electrolysis,” in: Aluminium, Verlag, Dusseldorf (1982).

L. I. Karyakin, Petrography of Refractories [in Russian], Metallurgizdat, Kharkov (1962).

A. I. Efimov, L. P. Belorukova, I. V. Vasil'kova, et al., Properties of Inorganic Compounds. Handbook [in Russian], Khimiya, Leningrad (1982).

V. P. Glushko (ed.), Thermal Constants of Materials. Handbook. Vol. 5 [in Russian], AN SSSR, Moscow (1971).

M. M. Vetyukov, “Electrometallurgy of Nonferrous Metals,” Trudy LPI, No. 239, 39–56 (1964).

Author information

Authors and Affiliations

Additional information

__________

Translated from Novye Ogneupory, No. 5, pp. 24 – 26, May, 2005.

Rights and permissions

About this article

Cite this article

Sharapova, V.V., Lishchuk, I.I., Boguslavskii, D.Y. et al. Mineral Composition and Phase Transformations in the Refractory Lining of the Bottom of Aluminum Electrolysis Cells. Part 2.. Refract Ind Ceram 46, 175–176 (2005). https://doi.org/10.1007/s11148-005-0078-2

Received:

Issue Date:

DOI: https://doi.org/10.1007/s11148-005-0078-2