Abstract

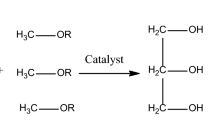

The present study investigated the synthesis of biodiesel through transesterification reaction of non-edible extracted oil from a cheap Rumex crispus leaves using a methanol alcohol in the presence of a nanocatalyst calcium oxide derived from mango seed shell. In line with this the synthesized calcium oxide nanocatalyst were characterized for structural patterns functional group, and energy band gab energy using XRD, FTIR and UV–Vis spectra. The effects of transesterification parameters; methanol to oil molar ratio, reaction temperature, reaction time, and catalyst loading on biodiesel yield were investigated and optimized by using a Response Surface Methodology (RSM) typically Central Composite Design (CCD). The catalyst loading turned out to be the most significant parameter with 93.72%. A 8:1 molar ratio of methanol to oil, a catalyst loading of 1.5 wt%, a reaction temperature of 65 °C and a reaction time of 3 h determines optimal conditions for the conversion of R. crispus leave oil to biodiesel yield of up to 93.72%. Under these conditions, the predicted and experimental biodiesel yields were 93.72% and 94.18%, respectively. The R2 value of the model was 0.9855, indicating the accuracy of the model. The biodiesel characterization parameters met the biodiesel specifications of European Standard (EN) EN14214 and characterized by GC–MS and FTIR analysis. The biodiesel produced from R. crispus leaves oil as an alternative energy source could be utilized as a substitute for fossil fuels for a variety of purposes while also improving sustainable energy utilization.

Similar content being viewed by others

Data availability

The availability of data, i.e., experimental design, data analysis (RSM), FTIR, Gas chromatography-mass spectrometry (GC–MS) used to support the results of this study are incorporated in the article.

Abbreviations

- ANOVA:

-

Analysis of variance

- CaO:

-

Calcium oxide

- CCD:

-

Central composite design

- FTIR:

-

Fourier transforms infrared

- GC–MS:

-

Gas chromatographs–mass spectroscopy

- FAC:

-

Fatty acids

- RSM:

-

Response surface methodology centered

References

Palani Y, Devarajan C, Manickam D, Thanikodi S (2022) Performance and emission characteristics of biodiesel-blend in diesel engine. A review. Environ Eng Res 27(1):200338

Ahmia AC, Danane F, Bessah R, Boumesbah I (2014) Raw material for biodiesel production. Valorization of used edible oil. J Renew Energies 17(2):335–343

Bayisa YM, Bullo TA, Hundie KB (2022) Optimizing process parameter for biodiesel production from avocado peel oil using chicken eggshell biocatalysts using central composite design (CCD). Reac Kinet Mech Cat 135(6):3185–3203

Zulqarnain, Mohd Yusoff MH, Ayoub M, Ramzan N, Nazir MH, Zahid I, Butt TA (2021) Overview of feedstocks for sustainable biodiesel production and implementation of the biodiesel program in Pakistan. ACS Omega 6(29):19099–19114

Adeniyi AG, Ighalo JO, Adeoye AS, Onifa DV (2019) Modelling and optimisation of biodiesel production from Euphorbia lathyris using ASPEN Hysys. SN Appl Sci 1(11):1452

Olagunju OA, Musonge P, Kiambi SL (2022) Production and optimization of biodiesel in a membrane reactor using a solid base catalyst. Membranes 12(7):674

Dharma S, Hassan MH, Ong HC, Sebayang AH, Silitonga AS, Kusumo F (2017) Optimization of biodiesel production from mixed Jatropha curcas–Ceiba pentandra using artificial neural network-genetic algorithm: evaluation of reaction kinetic models. Chem Eng Trans 56:547–552

Anwar M, Rasul M, Ashwath N, Rahman M (2018) Optimisation of second-generation biodiesel production from Australian native stone fruit oil using response surface method. Energies 11:2566

Ahmia AC, Danane F, Bessah R, Boumesbah I (2014) Raw material for biodiesel production Valorization of used edible oil. J Renew Energies 17(2):335–343

Fan X, Wang X, Chen F (2011) Biodiesel production from crude cottonseed oil: an optimization process using response surface methodology. Open Fuels Energy Sci J 4(1):1–8

Iqbal MF, Shad GM, Feng YL, Liu MC, Wang S, Lu XR, Tariq M (2019) Efficacy of postemergence herbicides for controlling curled dock (Rumex crispus L.) in wheat crops. Appl Ecol Environ Res 17(6):12753–12767

Amini R, Bahmani Y, Amjadi E, Nazari Z (2015) Effect of salinity and crop residue on seed germination and early seedling growth of curled dock (Rumex crispus L.). Int J Plant Anim Environ Sci 5(1):68–73

Bullo TA, Bayisa YM, Bultum MS (2022) Biosynthesis of sulfonated carbon catalyst from carbohydrate polymer derivatives for epoxidation of Croton macrostachyus seed oil. Carbohydr Polym Technol Appl 3:100221

Bullo TA, Bayisa YM, Bultum MS (2022) Optimization and biosynthesis of calcined chicken eggshell doped titanium dioxide photocatalyst based nanoparticles for wastewater treatment. SN Appl Sci 4(1):17

Talebian-Kiakalaieh A, Amin NA, Mazaheri H (2013) A review on novel processes of biodiesel production from waste cooking oil. Appl Energy 104:683–710

Gupta J, Agarwal M, Dalai AK (2016) Optimization of biodiesel production from mixture of edible and nonedible vegetable oils. Biocatal Agric Biotechnol 8:112–120

Habte L, Shiferaw N, Mulatu D, Thenepalli T, Chilakala R, Ahn JW (2019) Synthesis of nano-calcium oxide from waste eggshell by sol–gel method. Sustainability 11(11):3196

Panichikkal AF, Prakasan P, Kizhakkepowathial Nair U, Kulangara Valappil M (2018) Optimization of parameters for the production of biodiesel from rubber seed oil using onsite lipase by response surface methodology. Biotech 8:1–14

El-Gendy NS, Deriase SF, Hamdy A, Abdallah RI (2015) Statistical optimization of biodiesel production from sunflower waste cooking oil using basic heterogeneous biocatalyst prepared from eggshells. Egypt J Pet 24(1):37–48

Foroutan R, Mohammadi R, Ramavandi B (2021) Waste glass catalyst for biodiesel production from waste chicken fat: optimization by RSM and ANNs and toxicity assessment. Fuel 291:120–151

Rajesh K, Devan PK, Bharth Sai Kumar GK (2021) Parametric optimization and biodiesel production from coconut fatty acid distillate. Iran J Chem Chem Eng 40(1):343–355

El Boulifi N, Bouaid A, Martinez M, Aracil J (2010) Process optimization for biodiesel production from corn oil and its oxidative stability. Int J Chem Eng. https://doi.org/10.1155/2010/518070

Foroutan R, Mohammadi R, Esmaeili H, Bektashi FM, Tamjidi S (2020) Transesterification of waste edible oils to biodiesel using calcium oxide@ magnesium oxide nanocatalyst. Waste Manag 105:373–383

Lakshmana Naik R, Radhika N, Sravani K, Hareesha A, Mohanakumari B, Bhavanasindhu K (2015) Optimized parameters for production of biodiesel from fried oil. Int Adv Res J Sci Eng Technol 2(6):62–65

Hundie KB, Shumi LD, Bullo TA (2022) Investigation of biodiesel production parameters by transesterification of watermelon waste oil using definitive screening design and produced biodiesel characterization. S Afr J Chem Eng 41:140–149

Bullo TA, Fana FB (2021) Production and characterization of biodiesel from avocado peel oils using experimental analysis (ANOVA). J Eng Adv 2(02):104–111

Aworanti OA, Agarry SE, Ajani AO (2013) Statistical optimization of process variables for biodiesel production from waste cooking oil using heterogeneous base catalyst. Br Biotechnol J 3(2):116–132

Singh D, Kumar V, Sandhu SS, Sarma AK (2016) Process optimization for biodiesel production from indigenous non-edible Prunus armeniaca oil. Adv Energy Res 4(3):189

Bai L, Tajikfar A, Tamjidi S, Foroutan R, Esmaeili H (2021) Synthesis of MnFe2O4@ graphene oxide catalyst for biodiesel production from waste edible oil. Renew Energy 170:426–437

Dharma SM, Masjuki HH, Ong HC, Sebayang AH, Silitonga AS, Kusumo F, Mahlia TM (2016) Optimization of biodiesel production process for mixed Jatropha curcas–Ceiba pentandra biodiesel using response surface methodology. Energy Convers Manag 115:178–190

Elkady MF, Zaatout A, Balbaa O (2015) Production of biodiesel from waste vegetable oil via KM micromixer. J Chem 2015:630168

Jeyakumar N, Narayanasamy B, Venkatraman B (2021) Optimisation of biodiesel production from jack fruit seed oil using response surface methodology. Int J Ambient Energy 42(16):1864–1875

Acknowledgements

We would like to acknowledge the FT-IR Platform at the Faculty of Material Science and Engineering Faculty of Mechanical Engineering, School of Chemical Engineering Laboratory staff members at Jimma Institute of Technology for their knowledge sharing and technical support. This work was financially supported by the Jimma Institute of Technology Center of Excellence-CRGE RESOURCE CART (Climate Resilient Green Economy Resource Centre for Advanced Research and Training-Linking Energy with Water and Agriculture).

Funding

Not applicable.

Author information

Authors and Affiliations

Contributions

All the authors: TA wrote the main parts of the manuscript, YM, EB and VR have made a substantial contribution in conceptualization, data curation, formal analysis, methodology, designed the study and procedure, interpretation of the data, conducting lab testing, visualization, validation, analysis of FT-IR spectroscopy, and GC–MS analysis. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no competing interests.

Ethical approval

This article does not include human or animal studies conducted by any of the authors.

Informed consent

Consent to participate in the study was also obtained at the individual level.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bullo, T.A., Bayisa, Y.M., Jiru, E.B. et al. Optimization and clean synthesis of biodiesel from Rumex crispus leaves using calcium oxide derived from mango seed shell as a nanocatalyst. Reac Kinet Mech Cat 136, 2955–2975 (2023). https://doi.org/10.1007/s11144-023-02493-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-023-02493-x