Abstract

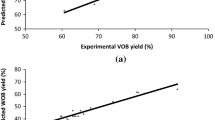

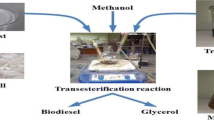

In this study, we investigated the application of waste avocado peel oil (WAPO) as a convenient and abundant source for biodiesel production using calcium oxide (CaO) biocatalysts derived from waste chicken eggshell via transesterification process. Likewise the functional group of extracted waste avocado peel oil and the structure of synthesized CaO biocatalyst were performed by using FT-IR (Fourier Transform Infrared Spectroscopy) and X-ray diffractometer analysis respectively. The physicochemical properties of the avocado peel oil and properties of biodiesel such as flash point, kinematic viscosity, density, cetane number, and acid number were also determined according to international standards. The optimum conditions were at a reaction temperature of 65 °C, a reaction time of 3 h, a catalytic load of 1.2 g, and a ratio of methanol to oil of 5:1 was achieved 94.45% with the desirability of 1 and the corresponding optimized biodiesel yield of 94.89%. The physicochemical properties of the avocado peel oil and the produced biodiesel were characterized using GC–MS to identify the composition of oil and biodiesel compound. The results represented that avocado peel oil can be used as a renewable feedstock source to produce biodiesel.

Similar content being viewed by others

Data availability

All data generated or analyzed during this study are included in this article and its supplementary files.

References

Math MC, Chandrashekhara KN (2016) Optimization of alkali catalyzed transesterification of safflower oil for production of biodiesel. J Eng. https://doi.org/10.1155/2016/8928673

Singh D, Kumar V, Sandhu SS, Sarma AK (2016) Process optimization for biodiesel production from indigenous non-edible Prunus armeniaca oil. Adv Energy Res 4:189–202

El-Gendy NS, Deriase SF, Hamdy A, Abdallah RI (2015) Statistical optimization of biodiesel production from sunflower waste cooking oil using basic heterogeneous biocatalyst prepared from eggshells. Egypt Pet Res Instit 24:37–48. https://doi.org/10.1016/j.ejpe.2015.02.004

Dinkar SK, Deep K (2019) Process optimization of biodiesel production using antlion optimizer. J Inf Optimiz Sci. https://doi.org/10.1080/02522667.2018.1491821

Anbessa TT, Karthikeyan S (2019) Optimization and mathematical modeling of biodiesel production using homogenous catalyst from waste cooking oil. Int J Eng Adv Technol 9:1733–1739

Beyecha K, Abdissa D (2022) Optimization of biodiesel production parameters from Prosopis julifera seed using definitive screening design. Heliyon 8:e08965. https://doi.org/10.1016/j.heliyon.2022.e08965

Aworanti OA, Agarry SE, Ajani AO (2013) Statistical optimization of process variables for biodiesel production from waste cooking oil using heterogeneous base catalyst. Egypt J Pet 3:116–132

Bello EI, Ogedengbe TI, Lajide L, Daniyan IA (2016) Optimization of process parameters for biodiesel production using response surface methodology. Am J Energy Eng 4:8–16

Nurdin M, Fatma F, Natsir M, Wibowo D (2017) Characterization of methyl ester compound of biodiesel from industrial liquid waste of crude palm oil processing. Anal Chem Res 12:1–9

Hundie KB, Shumi LD, Bullo TA (2022) Investigation of biodiesel production parameters by transesterification of watermelon waste oil using definitive screening design and produced biodiesel characterization. South Afr J Chem Eng 41:140–149. https://doi.org/10.1016/j.sajce.2022.06.002

Foroutan R, Mohammadi R, Ramavandi B (2021) Waste glass catalyst for biodiesel production from waste chicken fat: optimization by RSM and ANNs and toxicity assessment. Fuel 291:120–151. https://doi.org/10.1016/j.fuel.2021.120151

Naik L, Radhika N, Sravani K, Hareesha A, Mohanakumari B, Bhavanasindhu K (2015) Optimized parameters for production of biodiesel from fried oil. Int Adv Res J Sci Eng Technol 2:62–65

Foroutan R, Mohammadi R, Esmaeili H, Mirzaee Bektashi F, Tamjidi S (2020) Transesterification of waste edible oils to biodiesel using calcium oxide@magnesium oxide nanocatalyst. Waste Manag 105:373–383. https://doi.org/10.1016/j.wasman.02.032

Bai L, Tajikfar A, Tamjidi S, Foroutan R, Esmaeili H (2021) Synthesis of MnFe2O4@graphene oxide catalyst for biodiesel production from waste edible oil. Renew Energy 170:426–437. https://doi.org/10.1016/j.renene.2021.01.139

Ishola F, Adelekan D, Mamudu A, Abodunrin T, Aworinde A, Olatunji O (2020) Biodiesel production from palm olein: a sustainable bioresource for Nigeria. Heliyon. https://doi.org/10.1016/j.heliyon.2020.e03725

Boonmee K, Chuntranuluck S, Punsuvon V, Silayoi P (2010) Optimization of biodiesel production from jatropha oil (Jatropha curcas L.) using response surface methodology. Kasetsart J Nat Sci 44:290–299

Biernat K, Matuszewska A, Samson-Bręk I, Owczuk M (2021) Biological methods in biodiesel production and their environmental impact. Appl Sci. https://doi.org/10.3390/app112210946

Foroutan R, Mohammadi R, Razeghi J, Ramavandi B (2021) Biodiesel production from edible oils using algal biochar/CaO/K2CO3 as a heterogeneous and recyclable catalyst. Renew Energy 168:1207–1216. https://doi.org/10.1016/j.renene.2020.12.094

El-Gendy NS, Deriase SF, Hamdy A, Abdallah RI (2015) Statistical optimization of biodiesel production from sunflower waste cooking oil using basic heterogeneous biocatalyst prepared from eggshells. Egypt J Pet Egypt Pet Res Instit 24:37–48

Panichikkal AF, Prakasan P, Kizhakkepowathial Nair U, Kulangara Valappil M (2018) Optimization of parameters for the production of biodiesel from rubber seed oil using onsite lipase by response surface methodology. 3 Biotech 8:1–14. https://doi.org/10.1007/s13205-018-1477-7

Kyari MZ, Danggoggo SM, Usman BB, Muhammad AB (2018) Optimization of process variables in the biodiesel production from Lophira lanceolata seed oil. Niger J Basic Appl Sci 25:75. https://doi.org/10.4314/njbas.v25i2.9

Ngadi N, Hamdan NF, Onn Hassan RPJ (2016) Production of biodiesel from palm oil using egg shell waste as heterogeneous. J Teknol 9:59–63

Bullo TA, Bayisa YM, Bultum MS (2022) Biosynthesis of sulfonated carbon catalyst from carbohydrate polymer derivatives for epoxidation of Croton macrostachyus seed oil. Carbohydr Polym Technol Appl 3:100221. https://doi.org/10.1016/j.carpta.2022.100221

Bayisa YM, Bullo TA (2021) Optimization and characterization of oil extracted from Croton macrostachyus seed for antimicrobial activity using experimental analysis of variance. Heliyon 7:e08095. https://doi.org/10.1016/j.heliyon.2021.e08095

Siddiqua S, Al MA, Enayetul Babar SM (2015) Production of biodiesel from coastal macroalgae (Chara vulgaris) and optimization of process parameters using Box-Behnken design. Springer International Publishing 4:1–11

Bullo TA, Fana FB (2021) Production and characterization of biodiesel from avocado peel oils using experimental analysis (ANOVA). J Eng Adv 02:104–111

Nnodim CJ, Nwakaudu MS, Kamen FL, Nwakaudu AA, Ikhazuangbe PMO, Haruna I (2018) Statistical modeling and optimization of biodiesel production from Azadirachta Indica (Neem) using co-solvent technique. Int J Adv Eng Manag Sci 4:183–188

Marathe SJ, Jadhav SB, Bankar SB, Kumari Dubey K, Singhal RS (2019) Improvements in the extraction of bioactive compounds by enzymes. Curr Opin Food Sci 25:62–72

Dharma S, Haji M, Chyuan H, Hanra A (2017) Optimization of biodiesel production from mixed Jatropha curcas—Ceiba pentandra using artificial neural network-genetic algorithm. Eval Reac Kinet Models 56:547–552

Echabbi F, Hamlich M, Harkati S, Jouali A, Tahiri S, Lazar S (2019) Photocatalytic degradation of methylene blue by the use of titanium-doped calcined mussel shells CMS/TiO2. J Environ Chem Eng 7:103293

Bullo TA, Bayisa YM, Bultum MS (2022) Optimization and biosynthesis of calcined chicken eggshell doped titanium dioxide photocatalyst based nanoparticles for wastewater treatment. SN Appl Sci. https://doi.org/10.1007/s42452-021-04900-1

Bano S, Sha A, Sultana S, Sabir S, Khan MZ (2020) Fabrication and optimization of nanocatalyst for biodiesel production: an overview. Front Energy Res. https://doi.org/10.3389/fenrg.2020.579014

Math MC, Chandrashekhara KN (2016) Optimization of alkali catalyzed transesterification of safflower oil for production of biodiesel. J Eng (United Kingdom). https://doi.org/10.1155/2016/8928673

Foroutan R, Peighambardoust SJ, Mohammadi R, Ramavandi B, Boffito DC (2021) One-pot transesterification of non-edible Moringa oleifera oil over a MgO/K2CO3/HAp catalyst derived from poultry skeletal waste. Environ Technol Innov 21:101250. https://doi.org/10.1016/j.eti.2020.101250

Dhingra S, Bhushan G, Dubey KK (2016) Validation and enhancement of waste cooking sunflower oil based biodiesel production by the trans-esterification process. Energ Source Part A 38:1448–1454

Mohadesi M, Aghel B, Maleki M, Ansari A (2019) The use of KOH/Clinoptilolite catalyst in pilot of microreactor for biodiesel production from waste cooking oil. Fuel. https://doi.org/10.1016/j.fuel.2019.116659

Acknowledgements

The authors would like to acknowledge Jimma University (Jimma Institute of Technology), for internet-free usage.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Bayisa, Y.M., Bullo, T.A. & Hundie, K.B. Optimizing process parameter for biodiesel production from avocado peel oil using chicken eggshell biocatalysts using central composite design (CCD). Reac Kinet Mech Cat 135, 3185–3203 (2022). https://doi.org/10.1007/s11144-022-02327-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-022-02327-2