Abstract

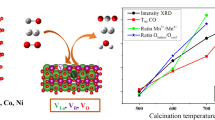

A series of perovskite-type oxide catalysts 40LaNi0.75Fe0.25−xMxO3/SiO2 (M=Ce, Zr) were synthesized by the citrate sol–gel method. The synthesized catalysts were characterized by various techniques such as BET, XRD, TEM, TGA, H2-TPR, FTIR, and Raman spectroscopy. The synthesized catalysts used for the dry reforming of methane (DRM) reaction at temperature 1073 K to produce synthesis gas. The effect of ceria and zirconia promoters on the percent conversion of CH4, CO2, and yield of the product was tested. An optimum ratio of (Fe–Ce) and (Fe–Zr) showed the highest yield and the highest conversion. The study demonstrated that the ceria or zirconia dispersed the excess nickel oxide present in the perovskite catalysts, which increased the conversion (CH4 and CO2), the stability of the catalysts and suppressed the carbon deposition during DRM. The percent yield obtained highest with the catalyst 40LaNi0.75Fe0.15Ce0.10O3/SiO2 and the highest percent conversion with the catalyst 40LaNi0.75Fe0.10Zr0.15O3/SiO2. The carbon formation was absent up to the 6 h of time-on-stream study during the DRM reaction. The catalyst maintained its activity without any deactivation.

Graphical abstract

Similar content being viewed by others

References

Mesrar F, Kacimi M, Liotta LF, Puleo F, Ziyad M (2018) Syngas production from dry reforming of methane over Ni/perlite catalysts: effect of zirconia and ceria impregnation. Int J Hydrogen Energy 43:17142–17155. https://doi.org/10.1016/j.ijhydene.2018.07.104

Lovell EC, Horlyck J, Scott J, Amal R (2017) Flame spray pyrolysis silica/ceria-zirconia supports for the carbon dioxide reforming of methane. Appl Catal A 546:47–57. https://doi.org/10.1016/j.apcata.2017.08.002

Munoz MA, Calvino JJ, Izquierdo JMR, Blanco G, Arias DC, Omil JAP, Garrido JCH, Leal JMG, Cauqui MA, Yeste MP (2017) Highly stable ceria-zirconia-yttria supported Ni catalysts for syngas production by CO2 reforming of methane. Appl Surf Sci 426:864–873. https://doi.org/10.1016/j.apsusc.2017.07.210

Moretti E, Storaro L, Talon A, Chitsazan S, Garbarino G, Busca G, Finocchio E (2015) Ceria-zirconia based catalysts for ethanol steam reforming. Fuel 153:166–175. https://doi.org/10.1016/j.fuel.2015.02.077

Cheah SK, Massin L, Aouine M, Steil MC, Fouletier J, Gellin P (2018) Methane steam reforming in water deficient conditions on Ir/Ce0.9Gd0.1O2−x catalysts: metal-support interactions and catalytic activity enhancement. Appl Catal B 234:279–289. https://doi.org/10.1016/j.apcatb.2018.04.048

Stekrova M, Paavoda AR, Karinen R (2018) Hydrogen production by aqueous phase reforming over nickel modified Ce, Zr, and La oxide supports. Catal Today 304:143–152. https://doi.org/10.1016/j.cattod.2017.08.030

Valderrama G, Goldwasser MR, Navarro CU, Tatibouet JM, Barrault J, Dupeyrat CB, Martinez F (2005) Dry reforming of methane over Ni perovskite type oxides. Catal Today 107–108:785–791. https://doi.org/10.1016/j.cattod.2005.07.010

Hu YH, Ruckenstein E (1996) An optimum NiO content in the CO2 reforming of CH4 with NiO-MgO solid solution catalysts. Catal Lett 36:145–149

Slagtern A, Olsbye U, Blom R, Dahl IM, Fjellvag H (1996) In situ XRD characterization of La-Ni-Al-O model catalysts for CO2 Reforming of methane. Appl Catal B 145:375–388. https://doi.org/10.1016/0926-860X(96)00157-3

Coronado I, Stekrova M, Moreno LG, Reinikainen M, Simell P, Karinen R, Lehtonen J (2017) Aqueous phase reforming of methanol over nickel-based catalysts for hydrogen production. Biomass Bioenerg 106:29–37. https://doi.org/10.1016/j.biombioe.2017.08.018

Wolfbeisser A, Sophiphun O, Bernardi J, Wittayakun J, Fottinger K, Rupprechter G (2016) Methane dry reforming over ceria-zirconia supported ni catalysts. Catal Today 277:234–245. https://doi.org/10.1016/j.cattod.2016.04.025

Bartholomew CH (1982) Carbon deposition in steam reforming of methanation. J Catal Rev Sci Eng 24:67–112. https://doi.org/10.1080/03602458208079650

Shiozaki R, Andersen AG, Hayakawa T, Hamakwa S, Suzuki K, Shimizu M, Takehira K (1997) Sustainable Ni/Ba/TiO3 catalysts for partial oxidation of methane to synthesis gas. Stud Surf Sci Catal 110:701–710. https://doi.org/10.1016/S0167-299(97)81032-4

Hayakawa T, Suzuki S, Nakamura J, Uchijima T, Hamakawa S, Suzuki K, Shishido T, Takehira K (1999) CO2 reforming of CH4 over Ni/perovskite catalysts prepared by solid phase crystallization method. Appl Catal A 183:273–285

Ben Hammouda S, Zhao F, Safaei Z, Babu I, Ramasamy DL, Sillanpaa M (2017) Reactivity of novel ceria-perovskite composites CeO2-LaMO3 (M=Cu, Fe) in the catalytic wet peroxidative oxidation of the new emergent pollutant “bisphenol F”: Characterization, kinetic and mechanism studies. Appl Catal B 218:119–136. https://doi.org/10.1016/j.apcatb.2017.06.047

Shikha P, Kang TS, Randhawa BS (2015) Effect of different synthetic routes on the structural, morphological, and magnetic properties of Ce doped LaFeO3 nanoparticles. J Alloys Compd 625:336–345. https://doi.org/10.1016/j.jallcom.2014.11.074

Valderrama G, Kiennemann A, Navarro CU, Goldwasser MR (2018) LaNi1−xMnxO3 Perovskite-Type Oxides As Catalysts Precursors For Dry Reforming Of Methane. Appl Catal A 565:26–33. https://doi.org/10.1016/j.apcata.2018.07.039

Kozuka H, Ohbayashi K, Koumoto K (2015) Electronic conduction in La-based perovskite-type oxides. Sci Technol Adv Mater 16:1–16

Daza CE, Gallego J, Mondragon F, Moreno S, Molina R (2010) High stability of Ce-promoted Ni/Mg-Al catalysts derived from hydrotalcites in dry reforming of methane. Fuel 89:592–603. https://doi.org/10.1016/j.fuel.2009.10010

Swirk K, Ronning M, Motak M, Grzybek T, Costa PD (2020) Synthesis strategies of Zr-and Y-promoted mixed oxides derived from double-layered hydroxides for syngas production via dry reforming of methane. Int J Hydrogen Energy. https://doi.org/10.1016/j.ijhydene.2020.239

Tsoukalou A, Imtiaz Q, Kim SM, Abdala PM, Yoon S, Muller CR (2016) Dry reforming of methane over bimetallic Ni-M/La2O3 (M=Co, Fe): the effect of the rate La2O2CO3 formation and phase stability on the catalytic activity and stability. J Catal 343:208–2014. https://doi.org/10.1016/j,jcat.201603.018

Atta NF, Galal A, E.H. EI-Ads, L. Pan, G. Zhu. (2016) Perovskite materials-synthesis, characterization, properties and applications. InTech. https://doi.org/10.1016/10.5772/61280

Sagar TV, Sreelatha N, Hannant G, Upendra K, Lingaiah N, Rama Rao KS, Satyanarayana CVV, Reddy IAK, Sai Prasad PS (2014) Methane reforming with carbon dioxide over La-Nix-Ce1−x mixed oxide catalysts. Indian J Chem 53A:478–483

Liu C, Chen D, Ashok J, Hongmanorom P, Wang W, Li T, Wang Z, Kawi S (2020) Chemical looping steam reforming of bio-oil for hydrogen-rich syngas production: effect of doping on LaNi0.8Fe0.2O3 perovskite. Int J Hydrogen Energy 45:21123–21137. https://doi.org/10.1016/j.ijhydene.2020.05.186

Koubaissy B, Pietraszek A, Roger AC, Kiennemann A (2010) CO2 reforming of methane Ce-Zr-Ni-Me mixed catalysts. Catal Today 157:436–439. https://doi.org/10.1016/j.cattod.2010.01.050

Das S, Bhattar S, Liu L, Wang Z, Xi S, Spivey JJ, Kawi S (2020) Effect of partial Fe substitution in La0.9Sr0.1NiO3 perovskite-derived catalysts on the reaction mechanism of methane dry reforming. Catalysis 10:12466–12486. https://doi.org/10.1021/acscatal.0c01229

Silva CKS, Baston EP, Meglar LZ, Bellido JDA (2019) Ni/Al2O3-La2O3 catalysts synthesized by a one-step polymerization method applied to the dry reforming of methane: effect of precursor structures of nickel perovskite and spinel. React Kinet Mech Catal 128:251–269. https://doi.org/10.1007/s11144-019-01644-3

Yadav PK, Das T (2019) Production of syngas from carbon dioxide reforming of methane by using LaNixFe1−xO3 perovskite type catalysts. Int J Hydrogen Energy 44:1659–1670. https://doi.org/10.1016/j.ijhydene.2018.11.108

Sohn JR, Kim HW, Park MY, Park EH, Kim JT, Park SE (1995) Highly active catalyst of NiO-ZrO2 modified with H2SO4 for ethylene dimerization. Appl Catal A 128:127–141. https://doi.org/10.1016/0926-860X(95)00057-7

Yi Y, Liu H, Chu B, Qin Z, Dong L, He H, Tang C, Fan M, Bin L (2019) Catalytic removal NO by CO over LaNi0.5M0.5O3 (M=Co, Mn, Cu) perovskite oxide catalysts: tune surface chemical composition to improve N2 selectivity. Chem Eng J 369:511–521. https://doi.org/10.1016/j.cej.2019.03.066

Khaleed AA, Bello A, Dangbegnon JK, Madito MJ, Ugbo FU, Akande AA, Dhonge BP, Barzegar F, Momodu DY, Mwakikunga BW, Manyala N (2017) Gas sensing study of hydrothermal reflux synthesized NiO/graphene foam electrode for CO sensing. J Mater Sci 52:2035–2044. https://doi.org/10.1007/s10853-016-0491-6

Reddy GK, Peck TC, Roberts CA (2019) CeO2-MxOy (M=Fe Co, Ni and Cu) Based Oxides For Direct NO decomposition. J Phys Chem 123:28695–28706. https://doi.org/10.1021/acs.jpcc.9b07736

Li K, Pei C, Li X, Chen S, Zhang X, Liu R, Gong J (2020) Dry reforming of methane over La2O2CO3-modified Ni/Al2O3 catalysts with moderate metal support interaction. Appl Catal B 264:118448–118456. https://doi.org/10.1016/j.apcatb.2019.118448

Das T, Nah IW, Choi JG, Oh IH (2016) Synthesis of iron oxide catalysts using various methods for the spin conversion of hydrogen. Reac Kinet Mech Catal 118:669–681. https://doi.org/10.1007/s11144-016-1035-4

Tang C, Sun B, Sun J, Hong X, Deng Y, Gao F, Dong L (2017) Solid state preparation of NiO-CeO2 catalyst for NO reduction. Catal Today 281:575–582. https://doi.org/10.1016/j.cattod.2016.05.026

Wang N, Liu J, Gu W, Song Y, Wang F (2016) Toward synergy of carbon and La2O3 in their hybrid as an efficient catalyst for the oxygen reduction reaction. R Soc Chem 6:77786–77795. https://doi.org/10.1039/c6ra17104d

Mondal T, Pant KK, Dalai AK (2015) Oxidative and non-oxidative steam reforming of crude bio-ethanol for hydrogen production over Rh promoted Ni/CeO2-ZrO2 catalyst. Appl Catal A 499:19–31. https://doi.org/10.1016/j.apcata.2015.04.004

Jbeli R, Boukhachem A, Saadallah F, Alleg S, Amlouk M, Ezzaouia H (2019) Synthesis and physical properties of Fe doped La2O3 thin films grown by spray pyrolysis for photocatalytic applications. Mater Res Express 6:066414–066424. https://doi.org/10.1088/2053-1591/ab0e29

Mrabet C, Ben AM, Boukhachem A, Amlouk M, Manoubi T (2016) Physical properties of LA-doped NiO sprayed thin films for optoelectronic and sensor applications. Ceram Int 42:5963–5978. https://doi.org/10.1016/j.ceramint.2015.12.144

Ashok J, Das S, Dewangan N, Kawi S (2019) H2S and NOx tolerance capability of CeO2 doped La1−xCexCo0.5Ti0.5O3−δ perovskites for steam reforming of biomass tar model reaction. Energy Convers Manag X1:100003–100015. https://doi.org/10.1016/j.ecmx.2019.100003

Acknowledgements

The authors thank for the financial support of SERB, DST (ECR/2016/001424), India, and the SMILE Scheme (SMILE-10/2017) to the Director and SRIC, IIT Roorkee for the instrument support by providing FTIR and Raman spectroscopy.

Author information

Authors and Affiliations

Contributions

PY: conceptualization, investigation, data correction, formal analysis, writing; TD: project administration, resources, supervision, reviewing, and editing.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Yadav, P.K., Das, T. Study of the perovskite-type catalysts 40LaNi0.75Fe0.25−X MXO3/SiO2 (M=Ce, Zr) for the dry reforming of methane. Reac Kinet Mech Cat 132, 279–300 (2021). https://doi.org/10.1007/s11144-021-01926-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11144-021-01926-9