Abstract

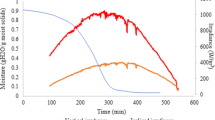

This study aimed to evaluate the solar dryers' cover material effects on the colorimetric and physicochemical properties of pumpkin flowers (Cucurbita maxima). A direct cabinet solar dryer was designed using three cover types: polycarbonate, polyethylene, and aluminum with selective surface (titanium oxide coating). A unifactorial experimental design with three levels was adopted. Pumpkin flower stability was assured by reducing the initial moisture content (95.22%) and water activity (0.989) to 3.15% and 0.276 in the polycarbonate dryer, to 3.03% and 0.279 in the selective surface dryer, and 5.19% and 0.364 in the polyethylene dryer. The drying kinetics showed that the drying time needed to achieve the moisture equilibrium was 480, 540, and 720 min in the respective dryers, depending on the ambient conditions. The initial pumpkin flower hue angle was 76.52°; however, this value decreased to 74.81, 69.52, and 70.23° in the dryers with polycarbonate, polyethylene, and the selective surface respectively; this behavior indicates a pumpkin flower tendency to orange color. The dryer with the selective surface obtained the best properties in pumpkin flowers. The pumpkin flower showed an initial total soluble solid of 1.5°Brix increased to 30°Brix in the polycarbonate and polyethylene dryers and 39°Brix in the selective dryer. The titanium oxide dryer observed an increment in ascorbic acid content from 3.5 to 8.806 mg/100 g, whereas 6.45 and 5.87 mg/100 g in the polycarbonate and polyethylene dryer, respectively.

Similar content being viewed by others

Data Availability

Data supporting the findings of this study are available from the corresponding author upon reasonable request.

References

Fornaris G (2012) Conjunto tecnológico para la producción de calabaza. Universidad de Puerto Rico. https://www.upr.edu/eea/wp-content/uploads/sites/17/2016/04/2.calabaza-caracteristicas-de-la-planta.pdf. Accessed 21 June 2022

SADR Secretaría de Agricultura y Desarrollo Rural (2016) Flor de calabaza, una belleza gastronómica. Publishing gob.mx website: https://www.gob.mx/agricultura/es/articulos/flor-de-calabaza-una-belleza-gastronomica. Accessed 21 June 2022

Ghosh P, Singh S (2021) Physicochemical, nutritional, bioactive compounds and fatty acid profling of pumpkin fower (Cucurbita maxima), as a potential functional food. Appl Sci 3:216. https://doi.org/10.1007/s42452-020-04092-0

Mulík S, Hernandez M, Pacheco S, Aguilar N, Ozuna C (2022) Culinary uses of mexican edible flowers: recipe analysis. Int J Gastron Food Sci 28:100539. https://doi.org/10.1016/j.ijgfs.2022.100539

Shantamma S, Vasikaran E, Waghmare R, Nimbkar S, Moses J, Anandharamakrishnan C (2021) Emerging techniques for the processing and preservation of edible flowers. Future Foods 4:100094. https://doi.org/10.1016/j.fufo.2021.100094

Toro K, Chavez R, Wessel L, Brunner B (2022) Production and postharvest assessment of tropical pumpkin flowers harvested for consumption. Horttechnology 32:199–212. https://doi.org/10.21273/HORTTECH04955-21

Kong D, Wang Y, Li M, Liu X, Huang M, Li X (2021) Analysis of drying kinetics, energy and microstructural properties of turnips using a solar drying system. Sol Energy 230:721–731. https://doi.org/10.1016/j.solener.2021.10.073

Devan P, Bibin C, Shabrin I, Gokulnath R, Karthick D (2020) Solar drying of fruits – a comprehensive review. Mater Today Proc 33:253–260. https://doi.org/10.1016/j.matpr.2020.04.041

Krabch H, Tadili R, Idrissi A, Bargach M (2022) Indirect solar dryer with a single compartment for food drying. Application to the drying of the pear. Sol Energy 240:131–139. https://doi.org/10.1016/j.solener.2022.05.025

Mongi R, Ngoma S (2022) Effect of solar drying methods on proximate composition, sugar profile and organic acids of mango varieties in Tanzania. Appl Food Res 2:100140. https://doi.org/10.1016/j.afres.2022.100140

Catorze C, Tavares A, Cardão P, Castro A, Silva M, Ferreira D, Lopes S, Brás I (2022) Study of a solar energy drying system—energy savings and effect in dried food quality. Energy Rep 8:392–398. https://doi.org/10.1016/j.egyr.2022.01.070

Peñaloza S, Delesma C, Muñiz J, Ortiz A (2022) The anthocyanin’s role on the food metabolic pathways, color and drying processes: an experimental and theoretical approach. Food Biosci 47:101700. https://doi.org/10.1016/j.fbio.2022.101700

Purohit S, Rana S, Idrishi R, Sharma V, Ghosh P (2021) A review on nutritional, bioactive, toxicological properties and preservation of edible flowers. Future Foods 4:100078. https://doi.org/10.1016/j.fufo.2021.100078

Jangde K, Singh A, Arjunan T (2022) Efficient solar drying techniques: a review. Environ Sci Pollut Res 29:50970–50983. https://doi.org/10.1007/s11356-021-15792-4

Rodríguez J, Méndez L, López A, Muñiz S, Nair K (2021) Solar drying of strawberry using polycarbonate with UV protection and polyethylene covers: influence on anthocyanin and total phenolic content. Sol Energy 221:120–130. https://doi.org/10.1016/j.solener.2021.04.025

Singh P, Shrivastava V, Kumar A (2018) Recent developments in greenhouse solar drying: a review. Renew Sust Energ Rev 82:3250–3262. https://doi.org/10.1016/j.rser.2017.10.020

Mhd N, Zainuddin Z, Syahriman M, Zulkifle I, Fudholi A, Hafidz M, Sopian K (2021) Current status of solar-assisted greenhouse drying systems for drying industry (food materials and agricultural crops). Trends Food Sci Technol 114:633–657. https://doi.org/10.1016/j.tifs.2021.05.035

López I, Ramos M, Zamilpa A, Bautista S, Ventura R (2021) Comparative analysis of the antioxidant compounds of raw edible flowers and ethanolic extracts of Cucurbita pepo, Tagetes erecta, and Erythrina americana during storage. J Food Process Preserv 45:15842. https://doi.org/10.1111/jfpp.15842

Aquino E, Corona R, Capistrán A, Chávez J (2016) Uso de diferentes películas plásticas de empaque para conserver la calidad poscosecha de flor de calabaza (Cucurbita máxima). Compendio de Investigaciones Científicas en México, pp 25–32. https://www.researchgate.net/publication/314092228. Accessed 14 March 2022

Karaaslan S, Ekinci K, Ertekin C, Kumbul B (2020) Thin layer peach drying in solar tunnel drier. Erwerbs-obstbau 63:65–73. https://doi.org/10.1007/s10341-020-00536-4

Berni P, Campoli S, Negri T, Toledo N, Brazaca C (2019) Non-conventional tropical fruits: characterization, antioxidant potential and carotenoid bioaccessibility. Plant Foods Hum Nutr 74:141–148. https://doi.org/10.1007/s11130-018-0710-1

Komonsing N, Reyer S, Khuwijitjaru MB, Müller J (2022) Drying behavior and curcuminoids changes in turmeric slices during drying under simulated solar radiation as influenced by different transparent cover materials. Foods 11:1–17. https://doi.org/10.3390/foods11050696

Ayua E, Mugalavai V, Simon J, Weller S, Obura P, Nyabinda N (2017) Comparison of a mixed modes solar dryer to a direct mode solar dryer for african indigenous vegetable and chili processing. J Food Process Preserv 41:13216. https://doi.org/10.1111/jfpp.13216

Rajkumar P, Kulanthaisami S, Raghavan G, Gariépy Y, Orsat V (2007) Drying kinetics of tomato slices in vacuum assisted solar and open sun drying methods. Dry Technol 25:1349–1357. https://doi.org/10.1080/07373930701438931

Yan J, Zhang L, Li X, Wu Q, Liu J (2022) Effect of temperature on color changes and mechanical properties of poplar/bismuth oxide wood alloy during warm-press forming. J Wood Sci 68:1–9. https://doi.org/10.1186/s10086-022-02032-7

Onwude D, Hashim N, Janius R, Nawi N, Abdan K (2017) Color change kinetics and total carotenoid content of pumpkin as affected by drying temperature. Ital J Food Sci 29:1–18. https://doi.org/10.14674/1120-1770%2Fijfs.v398

Zielinska M, Ropelewska E, Xiao H, Mujumdar A, Law C (2020) Review of recent applications and research progress in hybrid and combined microwave-assisted drying of food products: quality properties. Crit Rev Food Sci Nutr 60:2212–2264. https://doi.org/10.1080/10408398.2019.1632788

Pepa L, Rodríguez S, Santos C, Pilar M (2020) Interpretation of the color due to the ubiquitous nonenzymatic browning phenomena in foods. Color Res Appl 46:446–455. https://doi.org/10.1002/col.22574

Meléndez A, Benítez A, Corell M, Hernanz D, Mapelli P, Stinco C, Coyago E (2021) Screening for innovative sources of carotenoids and phenolic antioxidants among flowers. Foods 10:2625. https://doi.org/10.3390/foods10112625

Chuyen H, Roach P, Golding J, Parks S, Nguyen M (2016) Effects of four different drying methods on the carotenoid composition and antioxidant capacity of dried gac peel. J Sci Food Agric 97:1656–1662. https://doi.org/10.1002/jsfa.7918

Fernandes L, Casal S, Pereira J, Saraiva J, Ramalhosa E (2018) Effects of different drying methods on the bioactive compounds and antioxidant properties of edible centaurea (Centaurea cyanus) petals. Brazilian J Food Technol 21:1–10. https://doi.org/10.1590/1981-6723.21117

Minuye M, Getachew P, Laillou A, Chitekwe S, Baye K (2021) Effects of different drying methods and ascorbic acid pretreatment on carotenoids and polyphenols of papaya fruit in Ethiopia. Food Sci Nutr 9:3346–3353. https://doi.org/10.1002/fsn3.2324

Acknowledgements

To Investigadores for México CONACYT and the solar food drying laboratory IER-UNAM throughout the project PAPIIT IN103021 solar drying of agricultural products and CONACyT project 319188 Centro Comunitario para el Deshidratado Solar de Productos Agropecuarios de Pequeños Productores Indígenas en Hueyapan, Morelos

Funding

This research received no specific grant from any funding agency in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Contributions

O. García-Valladares: Conceptualization, writing, review and editing; A.M. Lucho-Gómez: Experimentation, E.A. Montiel-Baltazar: Investigation, M. Castañeda-Vazquez: Investigation; C.A. Ortiz-Sánchez: Experimentation, investigation; B. Castillo-Téllez: Validation, formal analysis; G. Luna-Solano: Methodology, A. Domínguez-Niño: Writing, review and editing.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Ethics Approval

Not applicable.

Consent to Participate

Informed consent was obtained from all participants included in the study.

Consent for Publication

All authors approve this manuscript for publication of results.

Conflict of Interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

García-Valladares, O., Lucho-Gómez, A.M., Montiel-Baltazar, E.A. et al. Effect of Modified Solar Dryers on Colorimetric and Physicochemical Properties of Pumpkin Flower (Cucurbita maxima). Plant Foods Hum Nutr 78, 139–145 (2023). https://doi.org/10.1007/s11130-022-01032-8

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11130-022-01032-8