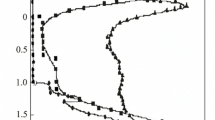

The paper examines the corrosion behavior of dense ZrB2-based ceramic samples in simulated seawater (3% NaCl solution) using polarization curves of electrochemical oxidation (ECO). The dense ceramic samples of 3–5% porosity were produced by hot pressing and had the following composition (wt.%): ZrB2, 77 ZrB2–23 SiC, 70 ZrB2–20 SiC–10 AlN, and 60 ZrB2–20 SiC– 20 (Al2O3–ZrO2). The main ECO parameters were the conduction current i, corrosion current icorr (i value at which di/dE decreased through diversion of some oxygen ions to oxidize the material), and anode potential Ea (E value at which the protective oxide film failed (i > 0)). A two-stage model of the ECO process was proposed upon analysis of the experimental data. At the first stage (E < Ea, i = 0), an oxide film developed on the effective surface: the higher the protective function of the oxide film, the greater its thermodynamic stability. The second ECO stage (E > Ea, i > 0) had two steps of changing the conduction current i, carried by negative oxygen ions. The first step was characterized by an avalanche-like increase in i at E = Ea up to maximum i = icorr, at which the rate of change in i decreased with increasing anode potential (di/dE). At higher icorr (second step), the increase in icorr with greater E slowed down through the interaction of oxygen with the test material, i.e., through oxidation. The higher the maximum icorr value, the greater the oxidation resistance of the material. According to the proposed model, the highest values of Ea and icorr in ECO conditions for ZrB2–SiC materials are reached when AlN is added as it promotes the formation of thermodynamically stable mullite in the protective film. An Al2O3–ZrO2 oxide addition increases the oxidation resistance of the material (high icorr values) but does not change the composition of the outer borosilicate glass film. This explains the close anode potentials of the 77 ZrB2–23 SiC (Ea= 0.1 V) and 60 ZrB2–20 SiC–20 (68 Al2O3–32 ZrO2) composites (Ea = 0 V).

Similar content being viewed by others

References

N. Fredj, S. Cohendoz, X. Feaugas, and S. Touzain, “Ageing of marine coating in natural and artificial seawater under mechanical stresses,” Prog. Org. Coat., 74(2), 391–399 (2012).

Xing-hong Zhang, Ping Hu, Lin Xu, and Song-he Meng, “The addition of lanthanum hexaboride to zirconium diboride for improved oxidation resistance,” Scr. Mater., 57, 1036–1039 (2007).

Daniel Doni Jayaseelan, Eugenio Zapata-Solvas, Peter Brown, and William E. Lee, “In situ formation of oxidation resistant refractory coating on SiC-reinforced ZrB2 ultra high temperature ceramics,” J. Am. Ceram. Soc., 74, 1–8 (2012).

V.A. Lavrenko, V.N. Talash, I.A. Podchernyaeva, A.D. Panasyuk, V.M. Panashenko, and D.V. Yurechko, “Corrosion behavior of zirconium diboride-based ceramics and electrospark coatings in 3% NaCl solution,” Powder Metall. Met. Ceram., 46, No. 1–2, 43–45 (2007).

V.A. Lavrenko, V.N. Talash, and V.A. Shvets, “Corrosion of AlN–TiN ceramics in 3% NaCl solution,” Powder Metall. Met. Ceram., 54, No. 5–6, 340–343 (2015).

V.A. Lavrenko, M. Desmaison-Brut, J. Desmaison, V.A. Shvets, and V.N. Talash, “Kinetics of electrochemical process on surface of TiB2–AlN, TiB2–TiN and TiC0.5N0.5 ceramics in 3% NaCl solution,” in: Abstr. Int. Conf. Advanced Materials, Kyiv, Ukraine (1999), p. 37.

G.V. Samsonov (ed.), Properties of Elements: Handbook [in Russian], Metallurgiya, Moscow (1976), p. 600.

O.N. Grigoriev, I.A. Podchernyaeva, D.V. Yurechko, A.U. Stelmakh, M.A. Vasilkovska, and V.M. Panashenko, “Structural and phase transformations in plasma-spray ZrB2–SiC–AlN coatings on an C/C–SiC substrate after high-temperature thermal cyclic heating,” Powder Metall. Met. Ceram., 58, No. 5–6, 341–350 (2019).

A.S. Berezhnoy, Multicomponent Oxide Systems [in Russian], Kyiv (1970), p. 572.

V.A. Shvets, V.N. Talash, V.A. Lavrenko, V.I. Subotin, and L.I. Kuznetsova, “Anodic oxidation of SiC–TiB2–B4C composites in 3% NaCl solution,” Powder Metall. Met. Ceram., 49, No. 11–12, 702–706 (2010).

V.A. Shvets, V.A. Lavrenko, V.N. Talash, and Yu.B. Rudenko, “Physicochemical properties of SiC–ZrB2 and SiC–ZrB2–ZrSi2 composites in high-temperature and electrochemical oxidation,” in: Int. Conf. Materials Science of Refractory Compounds: Advances and Issues (May 18–20, 2010, Kyiv) [in Russian], Inst. Probl. Materialoved. NAN Ukrainy, Kyiv (2010), p. 23.

Acknowledgment

The authors are grateful to Professor A.D. Panasyuk for providing compact ceramic samples for the experiments.

Author information

Authors and Affiliations

Corresponding author

Additional information

V.A. Lavrenko is deceased.

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 5–6 (539), pp. 111–117, 2021.

Rights and permissions

About this article

Cite this article

Grigoriev, O., Lavrenko, V., Podchernyaeva, I. et al. Physical Model for Electrochemical Oxidation of Composite Ceramics. Powder Metall Met Ceram 60, 346–351 (2021). https://doi.org/10.1007/s11106-021-00249-7

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00249-7