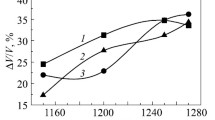

The features peculiar to the production of iron-based metal composites with additions of superfine composite powders synthesized as master alloys were studied. The composite powders resulted from the interaction of nanosized silicon carbide with iron oxide and sintered iron ore concentrate (SIOC). The superfine SiC–Fe2O3 and SiC–SIOC powder composites as master alloys contained multiple phases including silicon carbide, iron silicides, and silicon oxide and oxynitride (β-SiC, SiO2, β-Si3N4, Si2N2O, Fe2Si, Fe5Si3, FeO). The average particle size of the composite master alloy powders was 130 and 150 nm. Iron-based metal composites with 3, 5, and 7% master alloy were melted in an induction furnace at 1700°C for 40 min without a protective atmosphere through the complete dissolution of doping components and the formation of a homogeneous ferrite structure. Spectral analysis indicated that the total content of admixtures in the iron-based metal composites varied from 2.0 wt.% with a 3% master alloy addition to 4.1 wt.% with a 7% master alloy addition. The resultant alloys had a nanosized pearlite structure. The iron carbide lamellas reached 20–25 nm in size and the distance between them was no greater than 150 nm. Microdiffraction patterns showed α-Fe phase and nanocrystalline Fe3C and FeC carbides. The mechanical properties of the metal composites were examined. The addition of the synthesized superfine powder composites to the iron melt promoted excellent mechanical characteristics: in particular, the yield strength in uniaxial compression up to 1251 MPa, hardness (HV 10) up to 3.1 GPa, and plastic strain up to 31.1%. The influence of different heat treatment stages on the mechanical characteristics of the alloy was analyzed. Cold rolling of the pre-forged metal composites increased the yield stress to 1660 MPa and hardness to 4.4 GPa. Annealing of the metal composites at 700°C for 2 h resulted in 750 MPa yield stress, 34.5% plastic strain, and 2.5 GPa hardness.

Similar content being viewed by others

References

A.I. Gusev and A.A. Rempel, Nanocrystalline Materials [in Russian], Moscow (2001), p. 224.

R.Z. Valiev and I.V. Aleksandrov, Bulk Nanostructured Metallic Materials: Production, Structure, and Properties [in Russian], Moscow (2007), p. 398.

M.A. Meyers, A. Mishra, and D.J. Benson, “Mechanical properties of nanocrystalline materials,” Prog. Mater. Sci., 51, No. 4, 427–556 (2006).

I. I. Kositsyna, V. V. Sagaradze, and V. I. Kopylov, “Formation of high-strength and high-ductile state in metastable austenitic steels by equal-channel angular pressing,” Fiz. Met. Metalloved., 88, No. 5, 84–89 (1999).

A.V. Korznikov, I.M. Safarov, A.A. Nazarov, and R.Z. Valiev, “High strength state in low carbon steel with submicron fibrous structure,” Mater. Sci. Eng. A, 206, No. 1, 39–44 (1996).

M.D. Chapetti, H. Miyata, T. Tagawa, T. Miyata, and M. Fujioka, “Fatigue strength of ultra-fine grained steels,” Mater. Sci. Eng. A, 381, No. 1–2, 331–336 (2004).

O.V. Mikhailov, T.M. Pavlygo, G.G. Serdyuk, and L.I. Svistun, “Technology of sintered fine structural materials,” in: Rheology, Structure, and Properties of Powder and Composite Materials: Collected Scientific Papers [in Ukrainian], Lutsk State Tekh. Univ., Lutsk (2004), pp. 100–108.

L.N. Tyalina, A.M. Minaev, and V.A. Pruchkin, New Composite Materials: Handbook [in Russian], Tambov (2011), p. 80.

Yu.P. Vorobiev, “Carbides in steels,” Izv. Chelyab. Nauch. Tsentr., 23, Issue 2, 34–60 (2004).

Yu.S. Karabasov, New Materials [in Russian], Moscow (2002), p. 736.

J. Li, B.Y. Zong, Y.M. Wang, and W.B. Zhuang, “Experiment and modeling of mechanical properties on iron matrix composites reinforced by different types of ceramic particles,” Mater. Sci. Eng. A, 527, No. 29–30, 7545–7551 (2010).

Y. Wang, B. Y. Zong, Y. Yang, and J. Li, “SiC particulate reinforced iron matrix composites processed by specimen current heating hot press sintering,” TMS 2009, 138th Annual Meeting and Exhibition: Conference (2009), Vol. 3, pp. 395–401.

Y. Yang, Y. Zong, G. Wang, and N. Xu, “Manufacture of SiC particulate reinforced iron matrix composites by specimen current heating hot press sintering,” Chin. J. Mater. Res., 21, No. 1, 67–71 (2007).

S. Ito, K. Miyazaki, N. Yoneda, and K. Asaka, “Preparation of silicon carbide–iron composite using HIP,” J. Jpn. Soc. Powder Powder Metall., 36, No. 7, 831–836 (1989).

J. Pelleg, “Reactions in the matrix and interface of the Fe–SiC metal matrix composite system,” Mater. Sci. Eng. A, 269, No. 1–2, 225–241 (1999).

C. K. Srinivasa, C. S. Ramesh, and S. K. Prabhakar, “Blending of iron and silicon carbide powders for producing metal matrix composites by laser sintering process,” Rapid Prototyping J., 16, No. 4, 258–267 (2010).

B. Song, S. Dong, and C. Coddet, “Rapid in-situ fabrication of Fe/SiC bulk nanocomposites by selective laser melting directly from a mixed powder of micro-sized Fe and micro-sized SiC,” Scr. Mater., 75, 90–93 (2014).

C.L. Wu, S. Zhang, C.H. Zhang, J.B. Zhang, Y. Liu, and J. Chen, “Effects of SiC content on phase evolution and corrosion behavior of SiC-reinforced 316L stainless steel matrix composites by laser melting deposition,” Opt. Laser Technol., 115, 134–139 (2019).

Ya.G. Timoshenko and M.P. Gadzyra, “Phase formation and interaction between nanosized nonstoichiometric silicon carbide and iron oxide,” Powder Metall. Met. Ceram., 51, No. 5–6, 295–300 (2012).

M. Gadzira, G. Gnesin, O. Mykhaylyk, and O. Andreyev, “Synthesis and structural peculiarities of nonstoichiometric β-SiC,” Diamond Relat. Mater., 7, No. 10, 1466–1470 (1998).

N.F. Gadzyra, G.G. Gnesin, and A.A. Mykhailik, “Mechanism for the formation of a solid solution of carbon in silicon carbide,” Powder Metall. Met. Ceram., 40, No. 9–10, 519–525 (2001).

G. G. Gnesin, Silicon Carbide Materials [in Russian], Moscow (1977), p. 216.

I.V. Derevyanko, A.V. Zhadanos, and M.I. Gasik, “Melting of high-strength cast irons with spherical graphite based on synthetic and semisynthetic cast irons using byproduct materials of electrothermal production process,” Suchas. Probl. Metall., 19, Issue 1, 45–48 (2016).

V.I. Izotov, V.A. Pozdnyakov, E.V. Lukianenko, O. Yu. Usanova, and G.A. Filippov, “Effect of pearlite particle size on the mechanical properties, strain behavior, and fracture of high-carbon steel,” Fiz. Met. Metalloved., 103, No. 5, 549–560 (2007).

R. Tongsri and B. Vetayanugul, “Thermal analysis of Fe–carbide and Fe–C mixtures,” J. Met. Mater. Miner., 20, No. 1, 45–49 (2010).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 5–6 (539), pp. 82–91, 2021.

Rights and permissions

About this article

Cite this article

Tymoshenko, Y.G., Gadzyra, M., Davydchuk, N. et al. Structurization of Steel Produced from Iron Doped with a Nanosized Silicon Carbide Composite Powder. Powder Metall Met Ceram 60, 323–330 (2021). https://doi.org/10.1007/s11106-021-00243-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00243-z