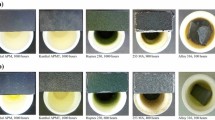

The interaction of titanium diboride with chromium was studied in the temperature range 1200– 1950°C in vacuum. A solid-phase reaction was established to proceed within two-hour holding at the contact boundary at up to 1580 ± 20°C to form a chromium diboride (Cr2B) layer 40 μm thick on the chromium side. Above 1580°C, the interaction process occurs according to the contact melting mechanism, being characteristic of eutectic systems. Chromium, a solid solution of titanium in chromium, chromium diboride Cr2B, and a phase of composition close to ternary boride Cr2TiB2 are predominant in the hypoeutectic region of the quasibinary phase diagram. The eutectic forms in the region of 1580°C at 14% titanium diboride. The liquid phase that emerges at 1600°C wets the diboride surface with a contact angle of ~75°. When temperature increases to 1950°C, the contact angle decreases to ~10°. The liquid phase interacting with TiB2 disappears as higher-temperature reaction products are formed. Binary (Cr2B, TiB) and ternary (Cr2TiB2) compounds based on titanium diboride and chromium lattices show up. The phase composition depends on the ratio of components in the alloy: the amount of reaction products increases with higher titanium diboride content. Considering the eutectic nature of the Cr–TiB2 quasibinary phase diagram, the small contact angle resulting from the interaction of titanium boride with the eutectic, and the capability of chromium to be uniformly distributed over the starting mixture through the vapor phase, chromium seems to be a promising element for activating the sintering process. Based on the studies conducted, a technique for the activated sintering of titanium diboride was developed and allowed its bending strength to be increased by 1.5 to 2 times.

Similar content being viewed by others

References

G.V. Samsonov, L.Ya. Markovskii, A.F. Zhigag, and V.A. Lyashko, Boron and Its Compounds and Alloys [in Russian], Izd. Akad. Nauk USSR, Kyiv (1960), p. 596.

G.V. Samsonov, T.I. Serebryakova, and V.A. Neronov, Borides [in Russian], Atomizdat, Moscow (1975), p. 374.

G.V. Samsonov and I.M. Vinitskii, Refractory Compounds [in Russian], Metallurgiya, Moscow (1976), p. 558.

S.S. Kiparisov, G.A. Libenson, and A.P. Pankevich, “On sintering mechanism in the production of lowporosity titanium diboride parts,” Izv. Vuz. Tsvet. Metall., No. 5, 145–149 (1974).

G.L. Zhunkovskii, P.V. Mazur, T.M. Evtushok, V.B. Vinokurov, L.V. Strashinskaya, M.G. Servetskaya, and T.I. Shaposhnikova, “Structure and some properties of composites based on double titanium–chromium boride,” in: Borides: Collected Scientific Paper [in Russian], Inst. Probl. Materialoved. AN USSR, Kyiv (1990), pp. 130–136.

S.C. Zhang, G.E. Hilmans, and W.G. Fahrenholtz, “Pressureless densification of zirconium diboride with boron carbide additions,” J. Am. Ceram. Soc., 89, No. 5, 1544–1550 (2006).

G.L. Zhunkovskii, T.M. Evtushok, B.U. Shagorova, and E.E. Ostapenko, “Sintering and hot pressing of materials produced from refractory compounds,” in: Sintering and Hot Pressing of Materials Produced from Refractory Compounds: Collected Scientific Papers [in Russian], Inst. Probl. Materialoved. AN USSR, Kyiv (1986), pp. 70–77.

G.L. Zhunkovskii, T.M. Evtushok, O.N. Grigoriev, V.A. Kotenko, and P.V. Mazur, “Activated sintering of refractory borides,” Powder Metall. Met. Ceram., 50, No. 3–4, 212–216 (2011).

O.N. Grigoriev, G.L. Zhunkovskii, D.V. Vedel, and V.O. Kotenko, “Features of zirconium boride–chromium interaction,” Powder Metall. Met. Ceram., 58, No. 7–8, 455–462 (2019).

O.N. Grigoriev, G.L. Zhunkovskii, D.V. Vedel, and N.D. Bega, “Component-interaction mechanism in the quasibinary HfB2–Cr system,” 58, Powder Metall. Met. Ceram., No. 9–10, 508–513 (2020).

I.M. Fedorchenko and R.A. Andrievskii, Fundamentals of Powder Metallurgy [in Russian], Izd. AN USSR, Kyiv (1961), p. 420.

A.D. Panasyuk, V.S. Fomenko, and G.G. Glebov, Stability of Nonmetallic Materials in Melts [in Russian], Naukova Dumka, Kyiv (1986), p. 352.

R.P. Elliot, Constitution of Binary Alloys [in Russian], Vol. 1, Metallurgiya, Moscow (1970), p. 456.

D. Kotzott, M. Ade, and H. Hillebrecht, “Synthesis and crystal structures of α- and β-modifications of Cr2IrB2 containing 4-membered B4 chain fragments, the τ-boride Cr7.9Ir14.1B6 and orthorhombic Cr2B,” Solid State Sci., No. 10, 291–302 (2008), DOI: https://doi.org/10.1016/j.solidstatesciences.2007.09.014.

G.V. Samsonov, Physicochemical Properties of Elements [in Russian], Naukova Dumka, Kyiv (1965), p. 808.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 5–6 (539), pp. 66–75, 2021.

Rights and permissions

About this article

Cite this article

Zhunkovskii, G.L., Grigoriev, O.N. & Vedel, D.V. The Interaction of Titanium Diboride with Chromium. Powder Metall Met Ceram 60, 310–317 (2021). https://doi.org/10.1007/s11106-021-00241-1

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00241-1