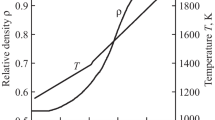

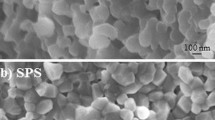

The time dependence of densification for a zirconium diboride powder during the isothermal sintering in vacuum assisted with applied pressure varying from 12 to 60 MPa in the range 2110– 2300°C and the nonisothermal pressure sintering with temperature being constantly increased by 20 and 40°C/min was studied experimentally. The densification kinetics was analyzed within the framework of continuum theory for bulk viscous flow taking the powder particle shape influenced the rheological properties of porous bodies into account. The densification kinetics was represented by equations describing nonlinear steady-state creep of the matrix forming a porous body. In isothermal sintering conditions, the root-mean-square strain rate is proportional to the fourth exponent of the root-mean-square stress. The creep is controlled by the dislocation climb mechanism with an estimated activation energy that is equal to 626 kJ/mol and is consistent with the activation energy for self-diffusion of atoms in the metal sublattice of borides. The estimated Laplace pressure is virtually comparable with the average applied pressure. The root-mean-square shear stress induced by additive pressure decreases with increase in the relative density and approaches zero at neartheoretical density of the material. The root-mean-square strain rate sharply decreases in the isothermal sintering process and increases reaching the maximum on the nonisothermal sintering curve. Two temperature ranges with different activation energies were found for nonisothermal pressure sintering. The higher temperature range is characterized by energies that are significantly greater than those for isothermal sintering and is indicative of endothermic process. The estimated critical cold brittleness temperature for zirconium diboride to transform to plastic condition is 1345°C.

Similar content being viewed by others

References

F. Monteverde, D.D. Fabbriche, and A. Bellosi, “Zirconium diboride-based composites,” Key Eng. Mater., 206–213, 961–964 (2002).

J.J. Meléndez-Martínez, A. Domínguez-Rodríguez, F. Monteverde, C. Melandri, and G. Portu, “Characterization and high temperature mechanical properties of zirconium boride-based materials,” J. Eur. Ceram. Soc., 22, Issues 14–15, 2543–2549 (2002).

A.L. Chamberlain, W.G. Fahrenholtz, and G.E. Hilmas, “Low-temperature densification of zirconium diboride ceramics by reactive hot pressing,” J. Am. Ceram. Soc., 89, Issue 12, 3638–3645 (2006).

J.K. Sonber, T.S.R.Ch. Murthy, C. Subramanian, Kumar Sunil, R.K. Fotedar, and A.K. Suri, “Investigations on synthesis of ZrB2 and development of new composites with HfB2 and TiSi2,” Int. J. Refract. Met. Hard Mater., 29, 21–30 (2011).

M.J. Thompson, Densification and Thermal Properties of Zirconium Diboride Based Ceramics, Doctoral Dissertations, p. 2150; https://scholarsmine.mst.edu/doctoral_dissertations/2150. 2012.

E.W. Neuman, Elevated Temperature Mechanical Properties of Zirconium Diboride Based Ceramics, Doctoral Dissertations, p. 2164; http://scholarsmine.mst.edu/doctoral_dissertations/2164. 2014.

M.W. Bird, R.P. Aune, A.F. Thomas, P.F. Becher, and K.W. White, “Temperature-dependent mechanical and long crack behavior of zirconium diboride–silicon carbide composite,” J. Eur. Ceram. Soc., 32, 3453–3462 (2012).

O.N. Grigoriev, V.B. Vinokurov, L.I. Klimenko, N.D. Bega, and N.I. Danilenko, “Sintering of zirconium diboride and phase transformations in the presence of Cr3C2,” Powder Metall. Met. Ceram., 55, No. 3–4, 185–194 (2016).

S. Chakraborty, P.K. Das, and D. Ghosh, “Spark plasma sintering and structural properties of ZrB2 based ceramics: a review,” Rev. Adv. Mater. Sci., 44, 182–193 (2016).

V.B. Vinokurov, M.S. Kovalchenko, L.I. Klimenko, N.D. Bega, and T.V. Mosina, “Kinetics of nonisothermal pressure sintering of zirconium diboride powder with additives of boron and chromium carbides in vacuum,” Powder Metall. Met. Ceram., 57, No. 1–2, 27–37 (2018).

M.S. Kovalchenko, “Pressure sintering kinetics of tungsten and titanium carbides,” Int. J. Refract. Met. Hard Mater., 39, 32–37 (2013).

V.V. Skorokhod, Rheological Fundamentals of Sintering Theory [in Russian], Naukova Dumka, Kyiv (1972), p. 151.

M.S. Kovalchenko, “Pressure sintering of powder materials,” Powder Metall. Met. Ceram.,” 50, No. 1–2, 18–33 (2011).

M.S. Kovalchenko, “Rheological models of pressure sintering of powders,” Powder Metall. Met. Ceram., 52, No. 1–2, 7–19 (2013).

M.S. Kovalchenko, “Rheology and kinetics of pressure sintering,” Mater. Sci. Forum, 835, 76–105 (2016).

M.S. Kovalchenko, T.P. Hrebenok, N.P. Brodnikovskii, and A.A. Rogozinskaya, “Features of brittle material powder compaction during pressing,” Powder Metall. Met. Ceram., 55, No. 5–6, 259–269 (2016).

D.S. Wilkinson and M.F. Ashby, “Pressure sintering by power law creep,” Acta Met., 23, 1277–1285 (1975).

T.P. Hrebenok, V.I. Subbotin, and M.S. Kovalchenko, “Densification kinetics of titanium carbide based cermet during the pressure sintering,” Aspects Min. Miner. Sci., 4, Issue 4, 517–518 (2020).

A. Angot, Mathematics for Electrical and Telecommunications Engineers [in French], Éditions de la Revue d’Optique, Paris (1949), p. 660.

J. Friedel, Dislocations, Pergamon Press, Oxford–London–Edinburgh–New York–Paris–Frankfurt (1964), p. 512.

G.P. Cherepanov, “Chapter 4. Physics of sintering,” in: Solid Mechanics and Its Applications, Vol. 51: Methods of Fracture Mechanics: Solid Matter Physics, Kluwer Academic Publishers, Dordrecht (1997), p. 333.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 5–6 (539), pp. 25–41, 2021.

Rights and permissions

About this article

Cite this article

Kovalchenko, M.S., Vinokurov, V.B., Litvin, R.V. et al. The Densification Kinetics of Porous Zirconium Diboride in Vacuum Pressure Sintering. Powder Metall Met Ceram 60, 278–290 (2021). https://doi.org/10.1007/s11106-021-00238-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00238-w