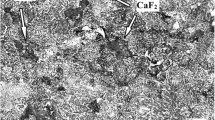

The paper analyzes the distribution of doping elements and their influence on the phase composition, structure, and tribological properties of a new self-lubricating copper-based antifriction composite doped with nickel, titanium, aluminum, and silicon, with additions of the CaF2 solid lubricant. The composite is intended for operation at elevated loads up to 2.0 MPa and high rotation speeds up to 10,000 rpm. The maps of chemical elements showed that they were uniformly distributed over the composite and there were no segregation phenomena. The homogeneous distribution of doping elements throughout the volume promoted strengthening phases that were uniformly distributed in the composite. These phases, together with the CaF2 solid lubricant distributed uniformly, increased the tribological properties in severe friction conditions. The composite’s high tribological properties were due to a uniform antiseize film that developed on the contact surfaces in operation, preventing the adhesion of surfaces and providing constant self-lubrication. The experimental results indicated that the new composite, Cu–(4.0–6.0)% Ni–(1.0–1.5)% Ti–(7.0–10.0)% Al–(0.5–0.8)% Si–(5.0–8.0)% CaF2, had greater antifriction characteristics than the well-known BrOTsS6-6-3 cast bronze used in the same operating conditions. In operation of the cast bronze, high rotation speeds lead to the ejection of the liquid lubricant by centrifugal forces from the contact area. The contact surfaces thus remain unprotected, which increases the friction coefficient and wear rate and leads to seizure of the contact surfaces. Homogeneous antiseize friction films make the new composite effective in operation without liquid lubrication at high rotation speeds and elevated loads. Such films act as a third, lubricating component in the friction unit along with the composite and the counterface. The antifriction copper-based composite can be recommended for friction units of high-speed web offset printing machines.

Similar content being viewed by others

References

A.P. Smirnyagin, Industrial Nonferrous Metals and Alloys [in Russian], Metallurgiya, Moscow (1974), p. 246.

A.G. Kostornov, Tribotechnical Materials Science [in Russian], Knowledge, Lugansk (2012), p. 696.

P.O. Kirichok, T.A. Roik, A.P. Gavrish, A.V. Shevchuk, and Yu.Yu. Vitsyuk, Novel Composites for Friction Parts of Printing Machines [in Ukrainian], NTUU Kyiv Politekh. Inst., Kyiv (2015), p. 428.

Powder Metal Technologies and Applications: The Materials International Society, ASM Handbook, Vol. 7, New York, USA (2015), p. 907, ISBN: 978-1-62708-089-3.

Liu Qian, Miguel Castillo-Rodríguez, Antonio Julio Galisteo, Roberto Guzman de Villoria, and José Manuel Torralba, “Wear behavior of copper–graphite composites processed by field-assisted hot pressing,” J. Compos. Sci., 29, No. 3, 1– 11 (2019).

T.A. Roik, O.A. Gavrysh, Yu.Yu. Vitsyuk, and O.I. Khmiliarchuk, “New copper-based composites for heavy-loaded friction units,” Powder Metall. Met. Ceram., 56, No. 9–10, 516–522 (2018).

H. Torres, M. Rodríguez Ripoll, and B. Prakash, “Tribological behavior of self-lubricating materials at high temperatures,” Int. Mater. Rev., 63, 309–340 (2018).

D. Jianxin and C. Tongkun, “Self-lubricant mechanisms via the in situ formed tribofilm of sintered ceramics with CaF2 additions when sliding against hardened steel,” J. Refract. Met. Hard Mater., 25, No. 2, 189–197 (2007).

T.A. Roik, O.A. Gavrysh, and Yu.Yu. Vitsyuk, Antifriction Copper-Based Composite [in Ukrainian], Ukrainian Patent 135076: IPC (2019.01) C22C9/02, C22C9/00, C22C1/00, C22C1/04, C22C1/05; T.A. Roik appl. patent hold., No. u201900876; appl. January 29, 2019; publ. June 10 (2019), Bulletin No. 11, p. 4.

K. Jamroziak, T. Roik, O. Gavrish, Iu. Vitsiuk, G. Lesiuk, J.A.F.O. Correia, and A. de Jesus, “Improved manufacturing performance of a new antifriction composite parts based on copper,” Eng. Fail. Anal., 91, 225–233 (2018).

T.A. Roik, A.P. Gavrysh, P.A. Kirichok, and Yu.Yu. Vitsyuk, “Effect of secondary structures on the functional properties of high-speed sintered bearings for printing machines,” Powder Metall. Met. Ceram., 54, No. 1–2, 119–127 (2015).

O.V. Bilotskii, High-Temperature Radiography of Phase Transformations in Metallic Materials [in Ukrainian], NTUU Kyiv Politekh. Inst., Kyiv (2012), p. 222.

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 60, Nos. 3–4 (538), pp. 79–87, 2021.

Rights and permissions

About this article

Cite this article

Roik, T.A., Gavrish, O.A. & Vitsiuk, I.I. The Phase Composition and Structure of the Antifriction Copper-Based Composite and their Influence on Tribological Properties. Powder Metall Met Ceram 60, 191–197 (2021). https://doi.org/10.1007/s11106-021-00227-z

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-021-00227-z