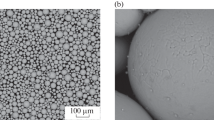

The main factors limiting the application of high-temperature creep-rupture resistant titanium alloys synthesized from powder components by pressing and subsequent vacuum sintering for the manufacture of parts for gas turbine engines are analyzed. The method for synthesizing the VT1-0 alloy and an alloy whose chemical composition corresponds to the high-temperature creep-rupture resistant VT8 alloy is described. Their chemical and phase composition, strength, hardness, and distribution of doping elements are examined. Upon analysis of the composition, structure, and properties of the samples produced from the test alloys synthesized from PT5 titanium powders with different particle sizes by powder metallurgy methods, it was concluded that semi-finished products could be produced from the VT1-0 and VT8 titanium alloys. The effect of the particle size of the titanium matrix on the chemical composition of the synthesized alloys is studied. The chemical composition of the test alloy complies with the industry standard for semi-finished products of hightemperature creep-rupture resistant titanium alloys. The influence of the particle-size distribution of titanium powder on the strength, hardness, and residual porosity of the synthesized alloys is established. Regardless of the particle size of the powder mixture matrix (ranging from 40 to 400 μm), the strength, ductility, and hardness of the test VT8 alloy do not comply with the requirements of standards OST 90002–70 and OST 90006–70, which govern these properties for bars and blanks of gas turbine engine blades. It is concluded that a series of measures are required to eliminate the residual porosity and impart the blade structure to the material to improve the strength properties.

Similar content being viewed by others

References

O.M. Ivasishin, D.G. Savvakin, K.A. Bondareva, V.S. Mokson, and V. A. Duz’, “Production of titanium alloys and parts by economical powder metallurgy method for large-scale industrial application,” Nauka Innovats., 1, No. 2, 44–57 (2005).

O.M. Ivasishin, V.M. Anokhin, A.N. Demidik, and D.G. Savvakin, “Cost effective blended elemental powder metallurgy of titanium alloys for transportation application,” Key Eng. Mater., 188, 55–62 (2000).

O.M. Ivasishin, A.P. Shpak, and D.G. Savvakin, “Economical powder metallurgy process of making titanium parts,” Titan, No. 1, 31–39 (2006).

O.M. Ivasishin, A.P. Shpak, and D.G. Savvakin, “Economical powder metallurgy process of making titanium parts,” in: Proc. Int. Conf. Titan-2005 in CIS (Kyiv", May 22–25, 2005), Mezhgos. Assots. Titan, Kyiv (2005), pp. 322–330.

O.M. Ivasishin, D. Eylon, V. Bondarchuk, and D.G. Savvakin, “Diffusion during powder metallurgy synthesis of titanium alloys,” Defect Diffus. Forum, 277, 177–185 (2008).

O.M. Ivasishin, K.A. Bondareva, A.I. Dekhtyar, D.G. Savvakin, A.N. Gripachevskii, and V.V. Tikhonovich, “Synthesis of Ti–Fe and Ti–Al–Fe alloys from elementary powder mixtures,” Metallofiz. Noveish. Tekhnol., 26, No. 7, 963–980 (2004).

O.M. Ivasishin, D.G. Savvakin, M.V. Matviychuk, and O.G. Molyar, “Effect of the doping method on the microstructure and properties of the Ti–5Al–5V–5Mo–3Cr alloy synthesized by powder component mixtures,” Nauk. Visti NTTU KPI, No. 4, 79–84 (2009).

D.V. Pavlenko, I.A. Ovchinnikova, S.I. Davydov, and A.A. Skrebtsov, “Production of complex master alloys for the synthesis of complex-doped titanium alloys by powder metallurgy method,” in: Construction, Materials Science, and Mechanical Engineering (Collected Scientific Papers) [in Russian], PGASA, Dnepropetrovsk (2015), Issue 80, pp. 235–240.

T.V. Pavlova, O.S. Kashapov, and N.A. Nochovnaya, “Titanium alloys for gas turbine engines,” Entsyklop. Sprav., No. 5, 8–14 (2012).

V.A. Boguslav, P.D. Zhemanyuk, A.V. Ovchinnikov, Z.V. Lechovitzer, and I.O. Bykov, “Use of titanium powders for producing parts for gas turbine engines by powder metallurgy methods,” Aviats. Kosm. Tekh. Tekhnol., No. 9/144, 86–91 (2017).

D.V. Pavlenko, T.A. Kovalenko, and A.V. Ovchinnikov, “Thermal effect on the structure and properties of the VT8M titanium alloy in submicron crystalline state,” Tekhnol. Syst., No. 1, 60–67 (2016).

Y.E. Beygelzimer, D.V. Pavlenko, O.S. Synkov, and O.O. Davydenko, "The efficiency of twist extrusion for compaction of powder materials," Powder Metall. Met. Ceram., 58, No. 1–2, 7–12 (2019).

V.A. Boguslaev, Yu.F. Basov, I.O. Bykov, A.V. Ovchinnikov, and Z.V. Lechovitzer, “Implementation of powder metallurgy methods in serial production of high-temperature creep-rupture resistance of titanium blades for gas turbine engines,” Aviats. Kosm. Tekh. Tekhnol., Issue No. 8/152, 54–59 (2018).

V.A. Boguslaev, V.K. Yatsenko, P.D. Zhemanyuk, G.V. Pukhalska, D.V. Pavlenko, and V.P. Ben, Finishing and Hardening of Gas Turbine Engine Parts [in Russian], Motor Sich Company, Zaporizhzhia (2005), p. 559.

D.V. Pavlenko, “Assessment of gas saturation of titanium alloys synthesized from powders using twist extrusion,” Powder Metall. Met. Ceram., 56, No. 5–6, 46–59 (2017).

D.V. Pavlenko, “Method for pressure shaping of sintered alloys in manufacture of parts for gas turbine engines,” Vest. Dvigatelestroy., No. 1, 83–92 (2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Poroshkova Metallurgiya, Vol. 58, Nos. 9–10 (529), pp. 146–158, 2019.

Rights and permissions

About this article

Cite this article

Bykov, I.O., Ovchinnikov, A.V., Pavlenko, D.V. et al. Composition, Structure, and Properties of Sintered Silicon-Containing Titanium Alloys. Powder Metall Met Ceram 58, 613–621 (2020). https://doi.org/10.1007/s11106-020-00117-w

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11106-020-00117-w